A sizing machine with uniform sizing and its application method

A sizing machine, a uniform technology, applied in the processing of textile materials, continuous processing of textile materials, textiles and papermaking, etc., can solve the problems of product quality and grade reduction, uneven sizing, sizing point, etc., to improve quality And grade, reduce the handling process, improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

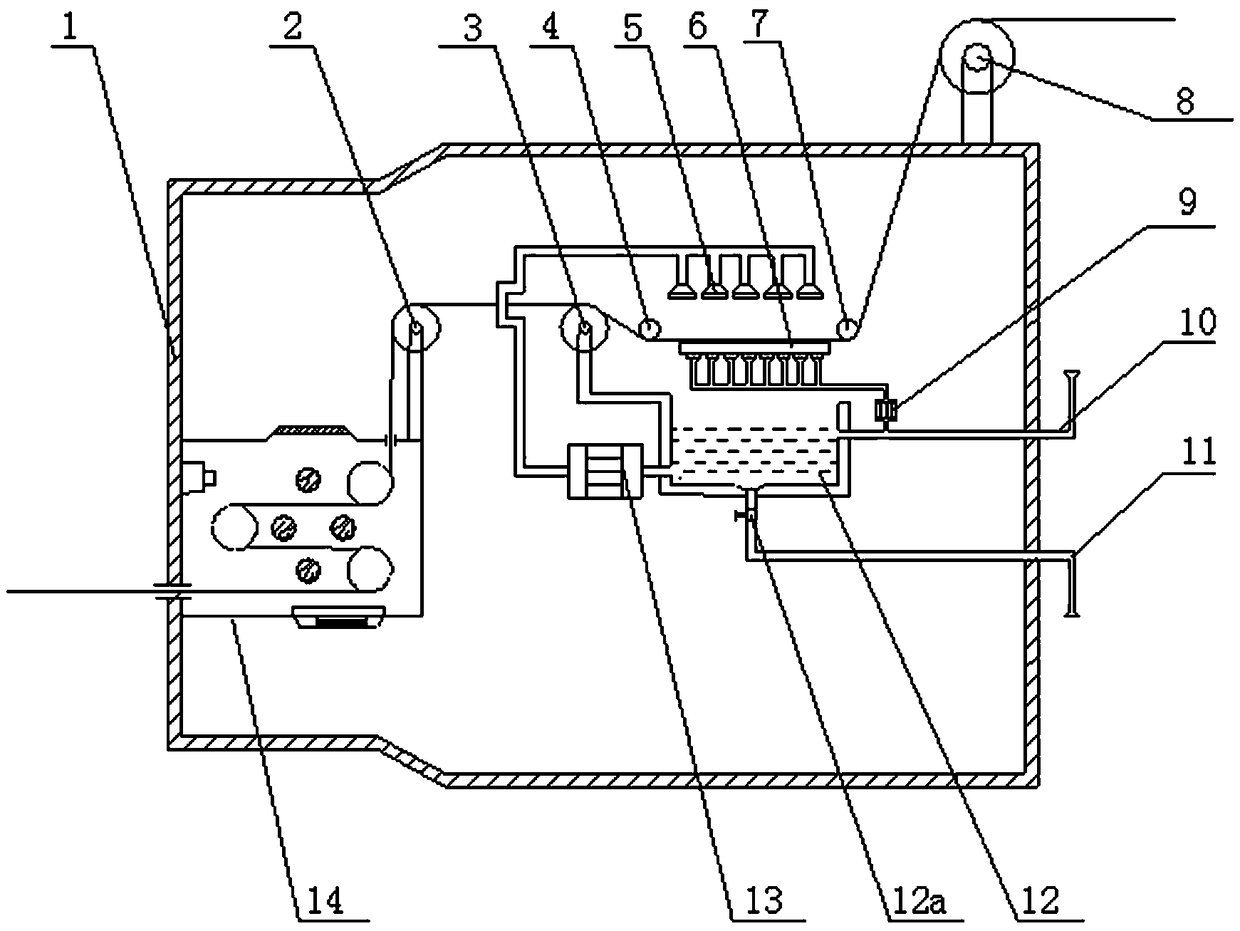

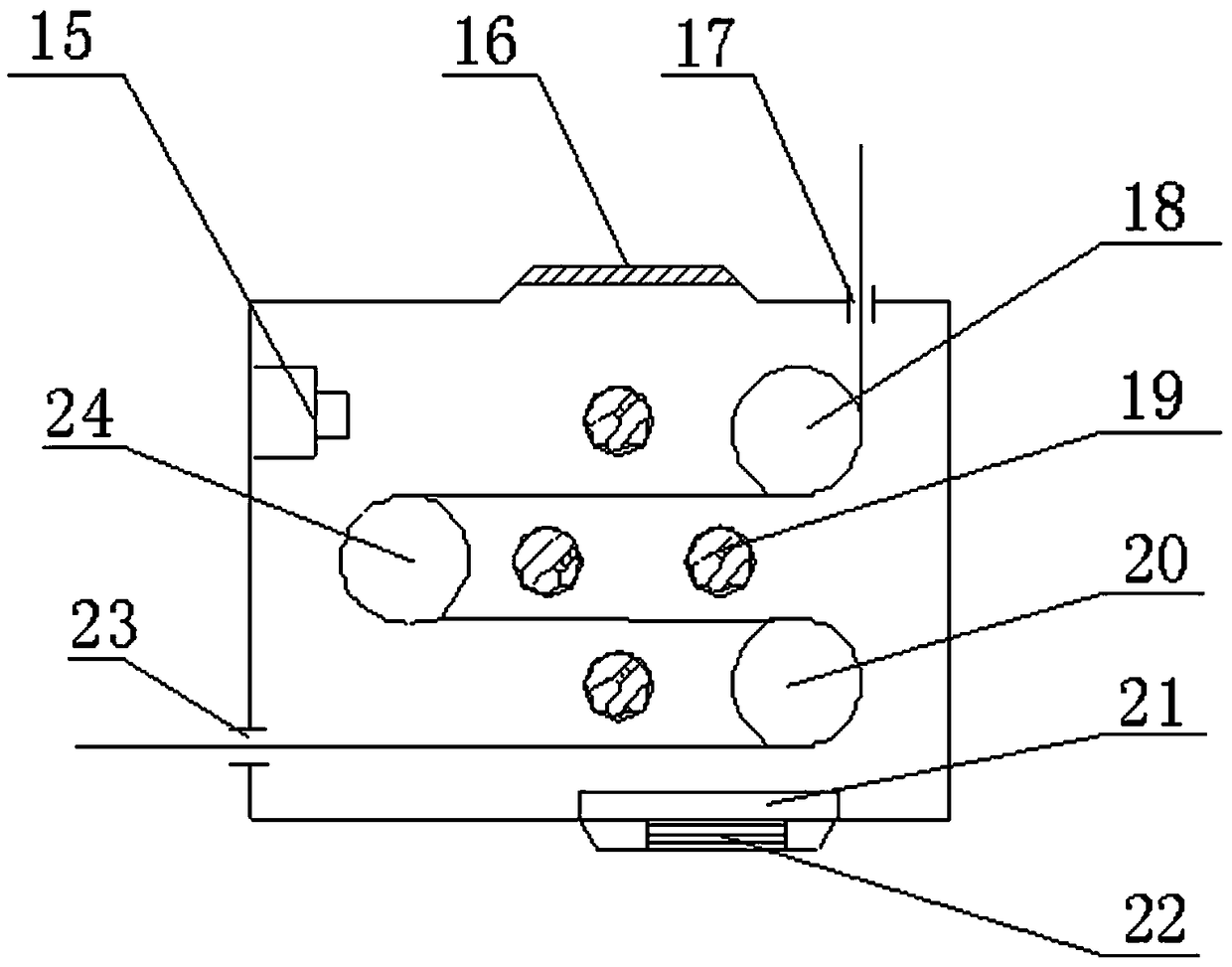

[0037] The sizing machine with uniform sizing of this embodiment, such as figure 1 , 2 As shown in and 3, it includes a casing 1, a slurry tank 12, a drying chamber 14 and a DC power supply (not shown in the figure), and the DC power supply is arranged in the casing 1. A front guide roller 8 is provided at the top front end of the casing 1. The front guide roller 8 is a conductor and is connected with the negative electrode of the DC power supply through a wire. The slurry tank 12 is fixedly arranged in the casing 1, and a slurry inlet pipe 10 is connected in front of the slurry tank 12. A discharge pipe 11 is connected below 12, and a valve 12a is provided on the discharge pipe 11. A front pressure roller 7 is provided above the slurry tank 12 near the front guide roller 8, and a rear pressure roller 7 is provided above the slurry tank 12 away from the front guide roller 8. Press roller 4;

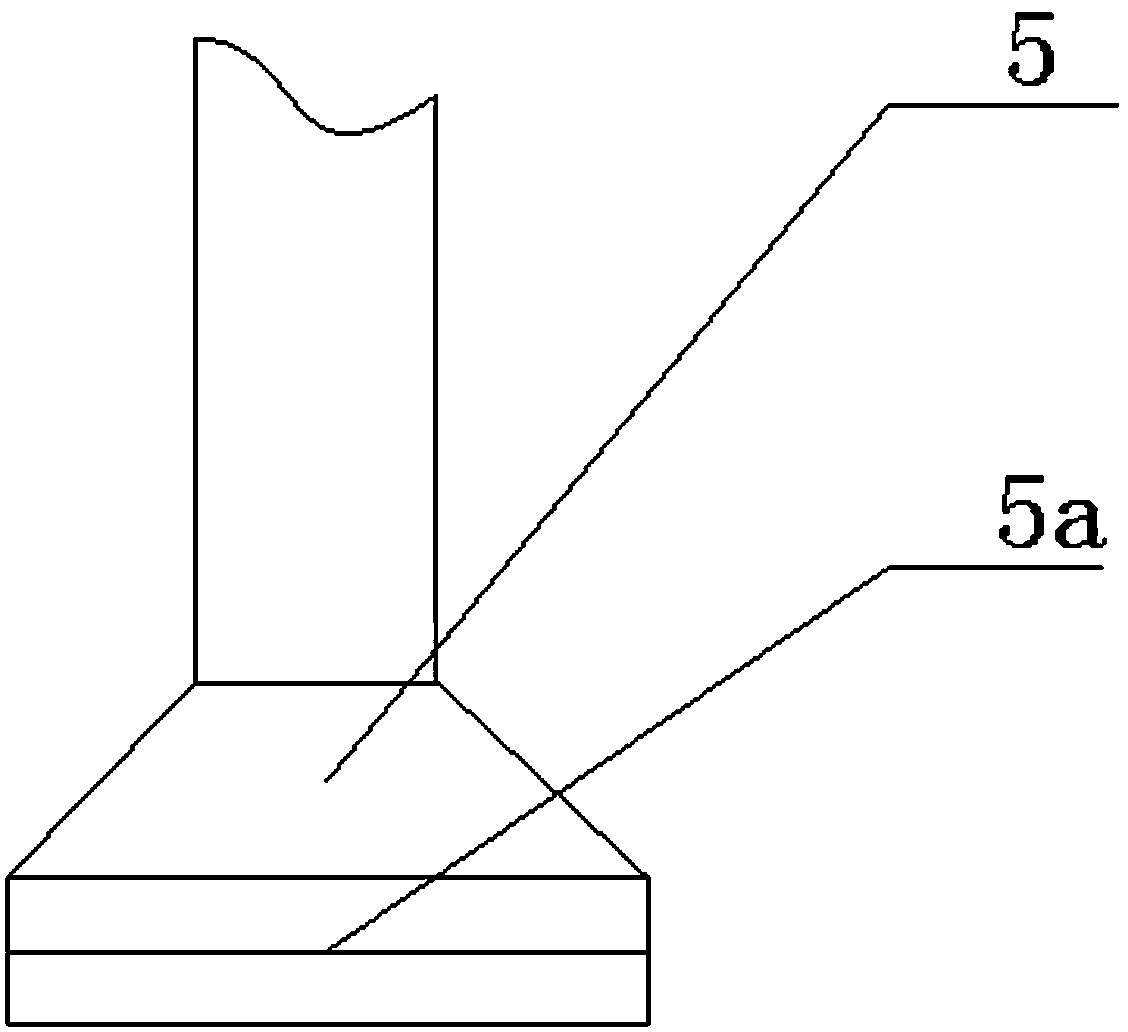

[0038] Five spray heads 5 are evenly spaced above the front pressure roller 7 and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com