Filler-free skidproof resin paint and its preparation method and use

A resin coating, no filler technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of short non-slip life, high cost, poor adhesion, etc., and achieve transparency, soft elasticity, long service life, and strong adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

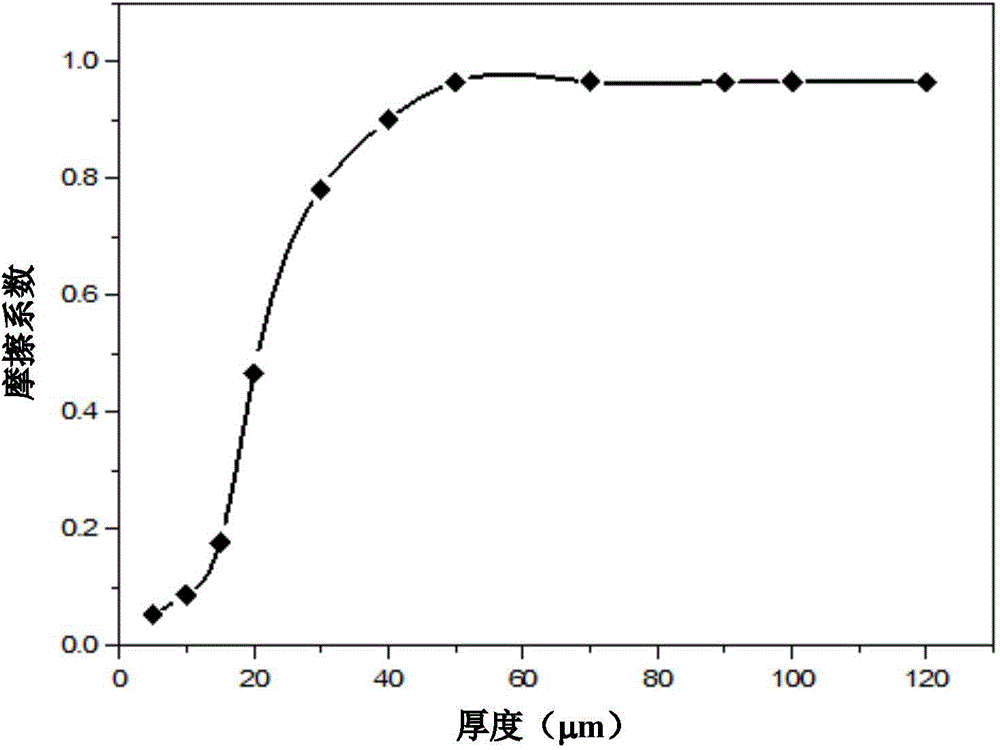

Image

Examples

Embodiment 1

[0036] Based on the total mass of the coating system 100wt%, 5wt% adhesion promoter Lanco-IntercoatVPP155 (Germany Lubrizol) is added to 35wt% solvent (by mass ratio, xylene: butyl acetate: ethyl acetate: diacetone alcohol = 1 :2:6:1), stirred at room temperature for 40min until fully dissolved, then added 50wt% epoxy modified polyether polyurethane resin elastic (M W =400g / mol, epoxy equivalent Ev=100g / eq), 1wt% leveling agent BYK333 (Germany BYK chemical), 1wt% wetting agent TEGOWET245 (Germany Digao), continue to stir for 30min, and add 3wt% catalyst ( Dibutyltin dilaurate (dibutyltin dilaurate, prepared as a toluene solution with a concentration of 10%)) was stirred evenly, and then 5 wt% curing agent HB100 (Basf, Germany) was added, and the anti-skid coating was obtained after stirring evenly. Transfer to the watering can, under the condition of 0.2~10MPa, the surface pretreatment (the surface treatment of the conventional substrate in this field includes: cleaning agent ...

Embodiment 2

[0038] Calculate with the total mass of the coating system 100wt%: 1wt% adhesion promoter Lanco-IntercoatVPP155 (Germany Lubrizol) is added to 35wt% solvent (by mass ratio, xylene: butyl acetate: ethyl acetate: diacetone alcohol=1 :2:6:1), stirred at room temperature for 40min to dissolve completely, then added 54wt% epoxy modified polyether polyurethane resin elastic (M W =400g / mol, epoxy equivalent Ev=100g / eq), 1wt% leveling agent BYK333 (Germany BYK chemical), 1wt% wetting agent TEGOWET245 (Germany Digao), continue to stir for 30min, and add 3wt% catalyst ( Dibutyltin dilaurate (dibutyltin dilaurate, prepared as a toluene solution with a concentration of 10%)) was stirred evenly, and then 6 wt% curing agent HB100 (Basf, Germany) was added, and the anti-skid coating was obtained after stirring evenly. Transfer to the watering can, under the condition of 0.2~10MPa, the surface pretreatment (the surface treatment of the conventional substrate in this field includes: cleaning a...

Embodiment 3

[0040] Calculating with 100wt% of the total mass of the coating system: add 9wt% adhesion promoter Lanco-IntercoatVPP155 (Germany Lubrizol) to 35wt% solvent (by mass ratio, xylene: butyl acetate: ethyl acetate: diacetone alcohol = 1 :2:6:1), stirred at room temperature for 40min until fully dissolved, then added 47wt% epoxy modified polyether polyurethane resin elastic (M W =400g / mol, epoxy equivalent Ev=100g / eq), 1wt% leveling agent BYK333 (Germany BYK chemical), 1wt% wetting agent TEGOWET245 (Germany Digao), continue to stir for 30min, and add 3wt% catalyst ( Dibutyltin dilaurate (dibutyltin dilaurate, prepared as 10% toluene solution) was stirred evenly, and then 4wt% curing agent HB100 (Germany BASF) was added and stirred evenly to obtain the anti-skid coating. Transfer to the watering can, under the condition that the air pressure of the spray gun is 0.2~10MPa, the surface treatment (the surface treatment of the conventional substrate in this field includes: cleaning agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com