Manufacturing method of fan-out type packaging structure

A technology of packaging structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of reduced overall chip thickness, high cost, and increased process complexity, so as to reduce product cost and packaging Thickness, the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described below in conjunction with drawings and embodiments.

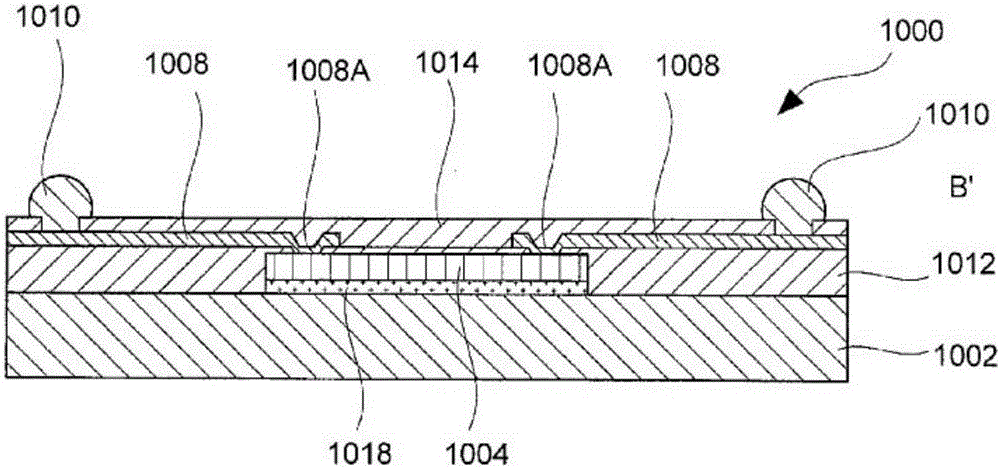

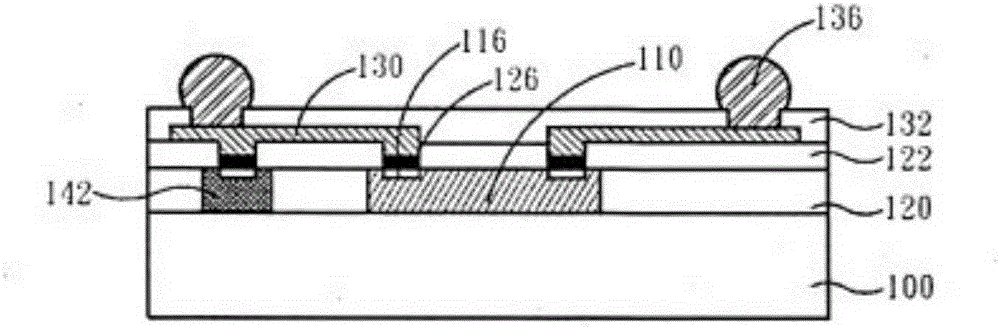

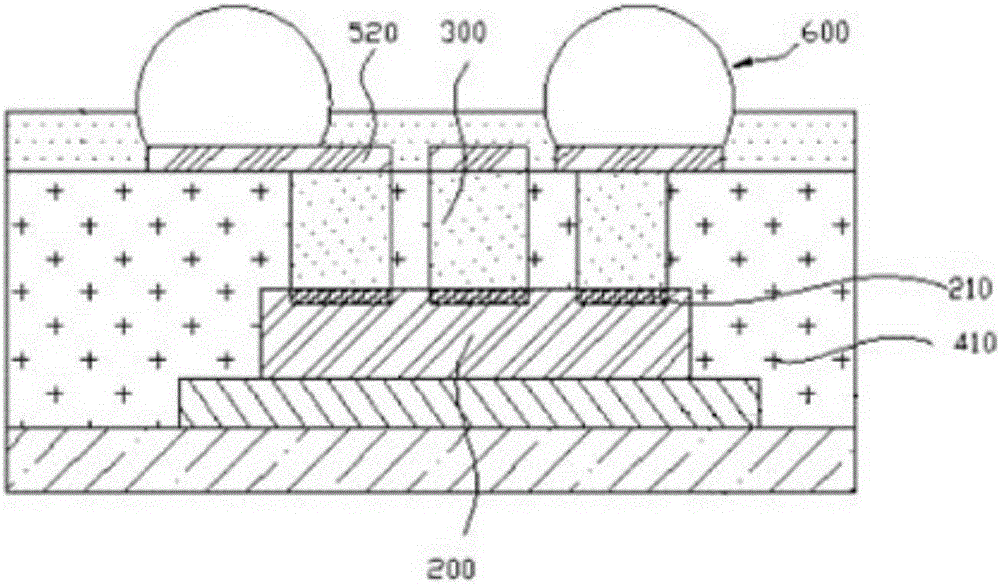

[0054] Such as Figure 4 As shown, the structure of the packaged product of the present invention includes a chip 102 with electrodes 104 on the front side of the chip 102 . The chip 102 may be a single chip or multiple chips, and may be an active chip or a passive chip.

[0055] The chip 102 actively faces upward, and the periphery of the chip 102 is filled with a first insulating resin layer 108. The top of the first insulating resin layer 108 is higher than the upper surface of the chip 102; the chip 102 and the top of the first insulating resin layer 108 are covered with a second insulating resin Layer 109, the surface of the second insulating resin layer 109 has a rewiring layer 112 connected to the electrode 104 of the chip through the opening of the second insulating resin layer 109, and the electrode 104 is drawn out through the rewiring layer 112. The redistr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com