Plugging agent and preparation method of same

A plugging agent and high-temperature stabilizer technology, applied in the field of plugging agent and its preparation, can solve problems such as poor plugging effect, and achieve good heat resistance, good thermal stability, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

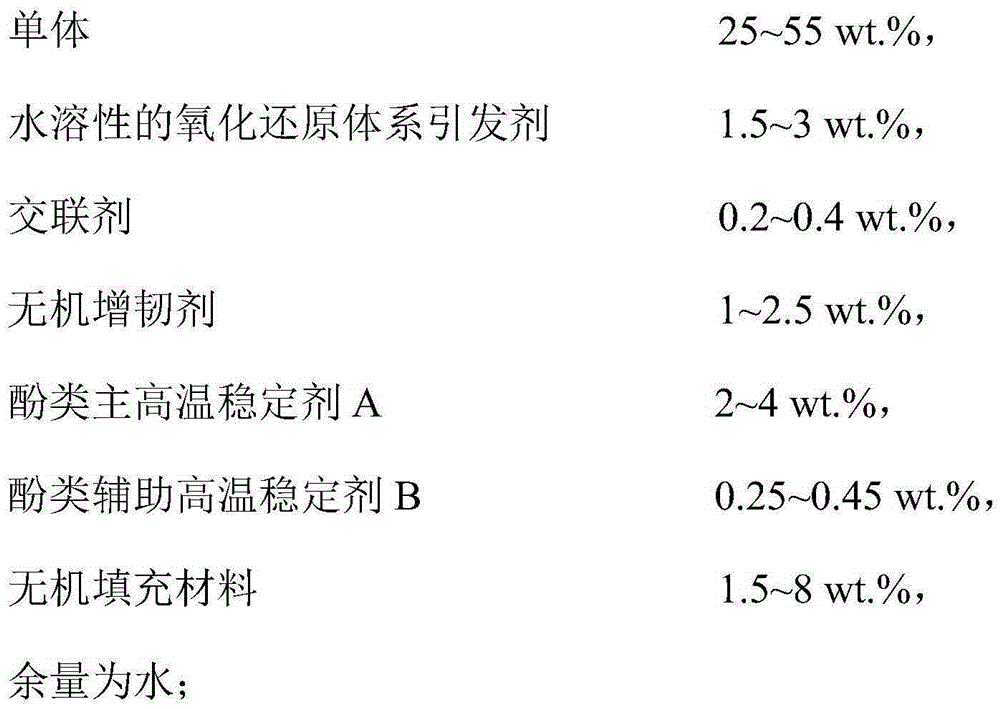

Method used

Image

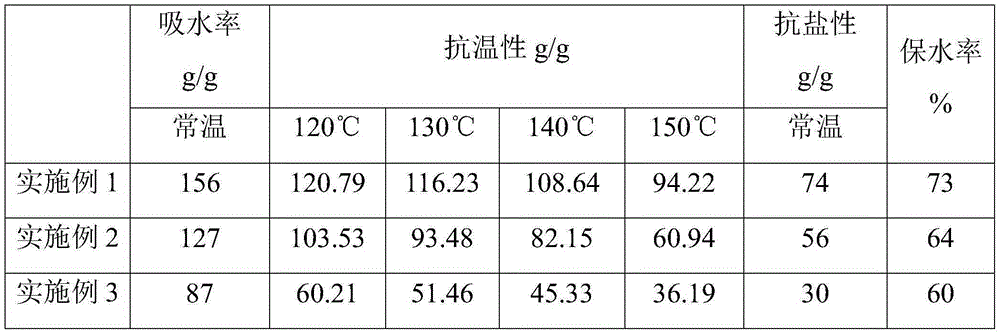

Examples

Embodiment 1

[0030] The substances selected in this embodiment are calculated by mass percentage: 18% of acrylamide, 12% of acrylic acid, 2% of sodium sulfite-potassium persulfate system (in which sodium sulfite and potassium persulfate are each 1%), N,N-methylenebis Acrylamide 0.2%, inorganic toughening agent superfine calcium carbonate 2%, antioxidant 10103.7%, antioxidant 1680.35%, sodium bentonite 2%, balance water. Wherein, the superfine calcium carbonate is calcium carbonate powder with an average particle diameter of 0.02-0.1 μm.

[0031] The preparation method of the leakage stoppage agent provided by the present embodiment comprises the following steps:

[0032] 1) Take each component according to the proportioning ratio, and set aside;

[0033] 2) Neutralize the acrylic acid solution with a sodium hydroxide solution with a concentration of 35wt.% until the neutralization degree is 80%, add water and stir until the solution is transparent to obtain a mixed solution A;

[0034] 3...

Embodiment 2

[0041] The substances selected in this embodiment are calculated according to mass percentage: 15% of acrylamide, 15% of acrylic acid, 1.8% of sodium sulfite-potassium persulfate system (wherein sodium sulfite and potassium persulfate are 0.9% each), N,N-methylenebis Acrylamide 0.14%, inorganic toughening agent superfine calcium carbonate 1.8%, antioxidant 10102.6%, antioxidant 1680.5%, sodium bentonite 2%, balance water. Wherein, the superfine calcium carbonate is calcium carbonate powder with an average particle diameter of 0.02-0.1 μm.

[0042] The preparation method of the leakage stoppage agent provided by the present embodiment comprises the following steps:

[0043] 1) Take each component according to the proportioning ratio, and set aside;

[0044] 2) Neutralize the acrylic acid solution with a sodium hydroxide solution with a concentration of 40wt.%, until the neutralization degree is 80%, add water, stir until the solution is transparent to obtain a mixed solution A...

Embodiment 3

[0052] The substances selected in this example are calculated according to mass percentage: 10% of acrylamide, 20% of acrylic acid, 1.5% of sodium sulfite-potassium persulfate system (in which sodium sulfite and potassium persulfate are each 0.75%), N,N-methylenebis Acrylamide 0.15%, inorganic toughening agent superfine calcium carbonate 2%, antioxidant 1010 2.1%, antioxidant DLTDP 0.45%, sodium bentonite 2%, balance water. Wherein, the superfine calcium carbonate is calcium carbonate powder with an average particle diameter of 0.02-0.1 μm.

[0053] The preparation method of the leakage stoppage agent provided by the present embodiment comprises the following steps:

[0054] 1) Take each component according to the proportioning ratio, and set aside;

[0055] 2) Neutralize the acrylic acid solution with a sodium hydroxide solution with a concentration of 45wt.%, until the neutralization degree is 75%, add water, stir until the solution is transparent to obtain a mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com