High performance super-amphiphobic conductive multi-functional corrosion-resistant coating and preparation method thereof

A kind of anti-corrosion coating and super amphiphobic technology, applied in the direction of coating, epoxy resin coating, fibrous filler, etc., to achieve the effect of unique structure, high effective specific surface area and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

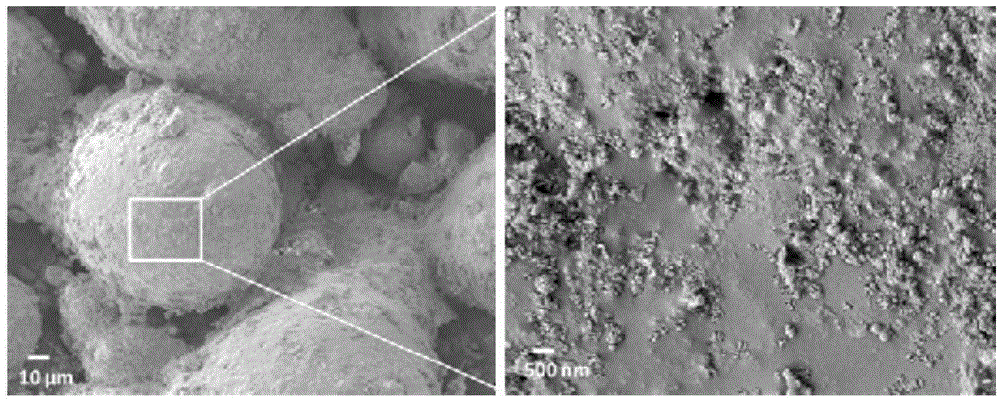

[0042] Using nano-silica as nano-filler and epoxy resin, ethylene-tetrafluoroethylene copolymer, and fluorinated ethylene-propylene copolymer as the coating matrix, a super-amphiphobic conductive coating with excellent anti-corrosion properties was prepared on an aluminum plate, and Test the anti-corrosion performance of the coating in the environment of strong acid, strong alkali and high concentration salt water.

[0043] (1) Carbon nanofiber modification

[0044] After mixing 30mL of concentrated nitric acid and 90mL of concentrated sulfuric acid, add 0.5g of carbon nanofibers, heat to 80°C with a constant temperature magnetic stirrer and stir for 4 hours at a constant temperature, after cooling to room temperature, wash with distilled water until neutral, and finally in an oven at 60°C Drying at low temperature for 24 hours to obtain carboxylated carbon nanofibers.

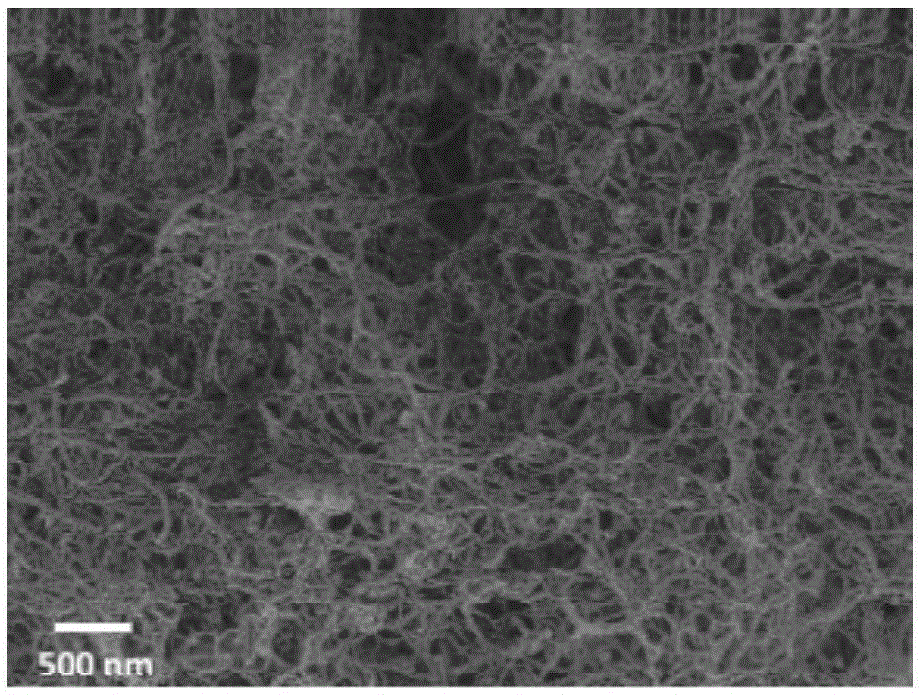

[0045] (2) Preparation of polyaniline / carbon nanofiber composites

[0046] Prepare 1L of sulfuric acid so...

Embodiment 2

[0061] Using nano-molybdenum disulfide as filler and epoxy resin, polydene tetrafluoroethylene, and fluorinated ethylene-propylene copolymer as the coating matrix, a super-amphiphobic conductive anti-corrosion coating was prepared on the steel plate.

[0062] Prepared according to the steps of Example 1, the difference with Example 1 is:

[0063] The concentration of carbon nanofibers in the mixed acid solution in step (1) is 3 mg / mL;

[0064] The mass ratio of aniline to carboxylated carbon nanofibers in step (2) is 1:0.2;

[0065] In step (3), the nanometer filler is molybdenum disulfide nanometer, the particle size is about 80nm, and the concentration is 3mg / mL;

[0066] In step (4), the coating base is a steel plate made of X80 material commonly used in petroleum pipelines; in the primer, linear aliphatic epoxy resin, polyamide curing agent, polyvinylidene fluoride, polyaniline / carbon nanofiber composite material, The mass ratio of ethyl acetate solvent is 1:0.15:0.2:0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com