Preparation method of NiCuZn ferrite thick film material used for Ka wave band circulator

A circulator and ferrite technology, applied in the field of electronic materials, can solve the problems of high microwave magnetic loss, low density, high porosity of thick film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The main component of the NiCuZn ferrite thick film material of the present invention is calculated by oxide mole percentage, and the dopant component is calculated by mass percentage. The preparation method of NiCuZn ferrite thick film of the present invention comprises the following steps:

[0019] 1. Main ingredient formula

[0020] Using 48.0~49.0mol% Fe 2 o 3 , 19-21.0mol% ZnO, 4.0-5.0mol% CuO, 26.0-27.0mol% NiO;

[0021] 2. One ball milling

[0022] Mix the above powders evenly in a planetary ball mill for 1 to 3 hours;

[0023] 3. Pre-burning

[0024] Dry the ball abrasive obtained in step 2, and pre-fire it in a muffle furnace at 800-1000°C for 1-3 hours;

[0025] 4. Doping

[0026] Add the following additives to the powder obtained in step 3: 0.05-0.1wt% CaO, 0.05-0.1wt% Bi 2 o 3 ;

[0028] Add 40-50 wt% organic binder (such as L-S composite binder) and 40-50 wt% absolute ethanol to the powder obtained in step 4, and ball...

Embodiment 1

[0038] 1. Formula

[0039] The main ingredient formula is 49.0mol% Fe 2 o 3 , 20.0mol% ZnO, 5.0mol% CuO, 26.0mol% NiO;

[0040] 2. One ball milling

[0041] Mill the above powder in a planetary ball mill for 1 to 3 hours;

[0042] 3. Pre-burning

[0043] Dry the ball abrasive obtained in step 2, and pre-fire it in a muffle furnace at 900°C for 2.5 hours;

[0044] 4. Doping

[0045] Add additives to the powder obtained in step 3: 0.1wt% CaO, 0.1wt% Bi 2 o 3 ;

[0046] 5. Ball mill slurry

[0047] Add 40-50wt% organic binder and 40-50wt% absolute ethanol to the powder obtained in step 4, and ball mill in a planetary ball mill for 4-8 hours;

[0048] 6. Tape casting

[0049] Cast the slurry obtained in step 5 on a semi-automatic casting machine to cast a 50-60 μm raw film tape;

[0050] 7. Lamination

[0051] Laminate 20-22 layers of film on the raw film belt obtained in step 6 at 80°C and 6Mpa to make a green part with a thickness of 100-140 μm;

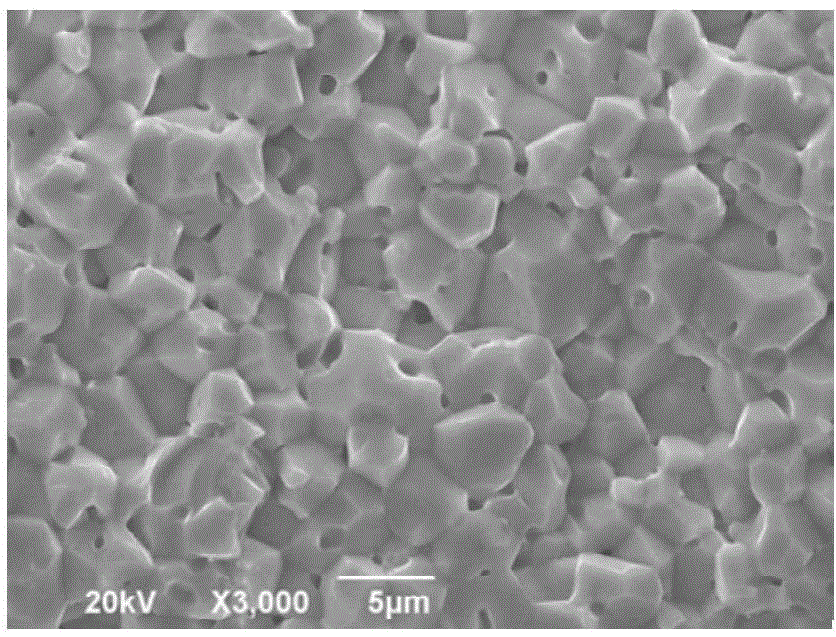

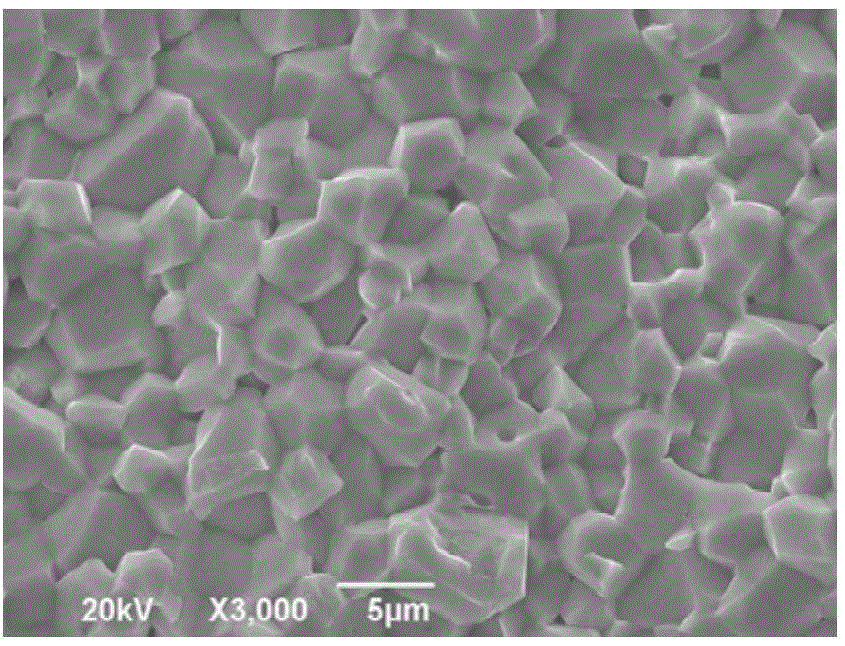

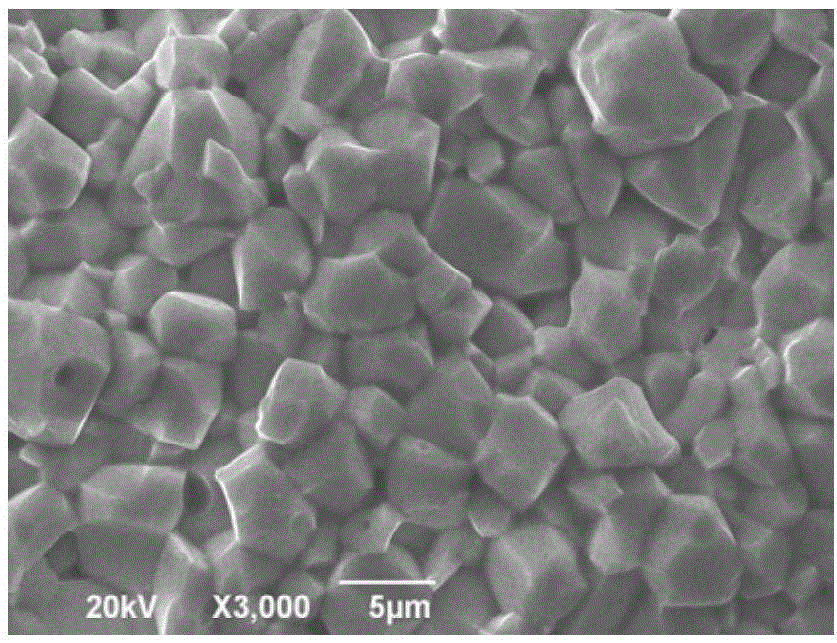

[0052] 8. Sinteri...

Embodiment 2

[0055] The difference between this embodiment and embodiment 1 is that the sintering temperature in step 8 is 1060°C.

[0056] The performance index of embodiment 1,2 is as table 1.

[0057] Table 1 embodiment 1~2 test result

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Curie temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com