Method for preparing micro-droplets based on micro-fluidic chip modification technology

A microfluidic chip and micro-droplet technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of high hydroxyl content of hydrolyzate, low activity of hydrolyzate, easy gelation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Example 1: Preparation of water-in-oil microfluidic chips using the modified polymethyl methacrylate microfluidic chip of the present invention droplet

[0060] Specific steps are as follows:

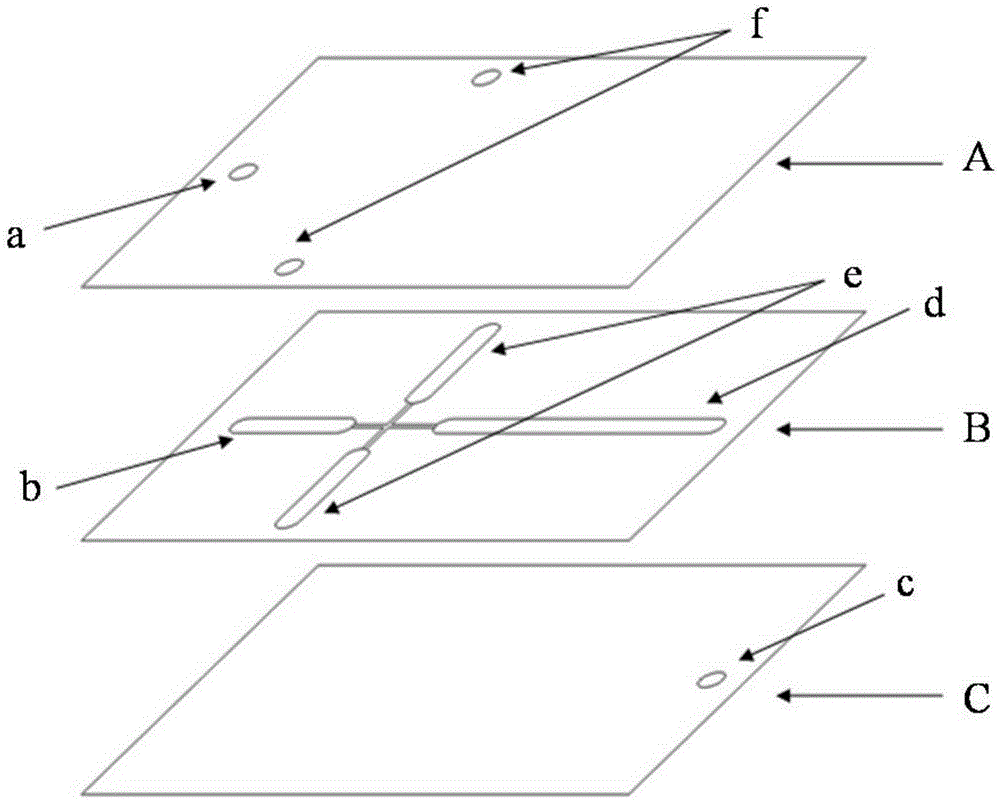

[0061] Step 1: Design of polymethyl methacrylate microfluidic chip: design each layer of polymethyl methacrylate microfluidic chip, the designed chip is composed of 3 layers, they are capping layer, The chip layer and the base layer, wherein the capping layer is processed with 1 dispersed phase inlet and 2 continuous phase inlets, the chip layer is processed with microchannels, and the base layer is processed with 1 droplet collection outlet;

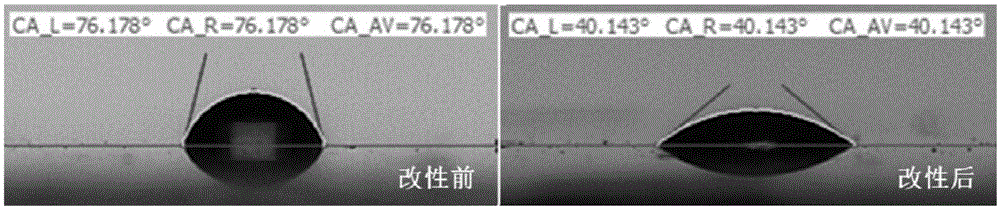

[0062] Step 2: Fabrication of polymethyl methacrylate microfluidic chip: using CO 2 The laser engraving machine processes each layer described in step 1; when processing the capping layer, CO 2 The power of the laser engraving machine is 95%, and the cutting speed is 50%; when processing the chip layer, CO 2 The power of the laser e...

Embodiment 2

[0072] Example 2: Using the modified polymethyl methacrylate microfluidic chip of the present invention to prepare a pack of multi-type microfluidic chips droplet

[0073] Specific steps are as follows:

[0074] The hydrophilic modified polymethyl methacrylate microfluidic chip was prepared as described in Example 1.

[0075] Deionized water and vegetable oil were stirred at a high speed at a volume ratio of 5:1, the stirring speed was 18000rpm, and the stirring time was 5 minutes to obtain a dispersed phase solution; 5mL of the above dispersed phase solution and 10mL of the continuous phase solution (ethylene dimethacrylate Alcohol ester 10g, polyglyceryl ricinoleate 0.5g) is injected into the microfluidic chip from the corresponding inlet with a flow ratio of 1:5, and a series of one-pack multi-type micro-droplets are obtained. Droplets exit the droplet collection outlet of the base layer and are collected in a petri dish supplemented with the same collection phase as t...

Embodiment 3

[0076] Example 3: Preparation of porous polymers using the modified polymethyl methacrylate microfluidic chip of the present invention particles

[0077] Specific steps are as follows:

[0078] The hydrophilic modified polymethyl methacrylate microfluidic chip was prepared as described in Example 1.

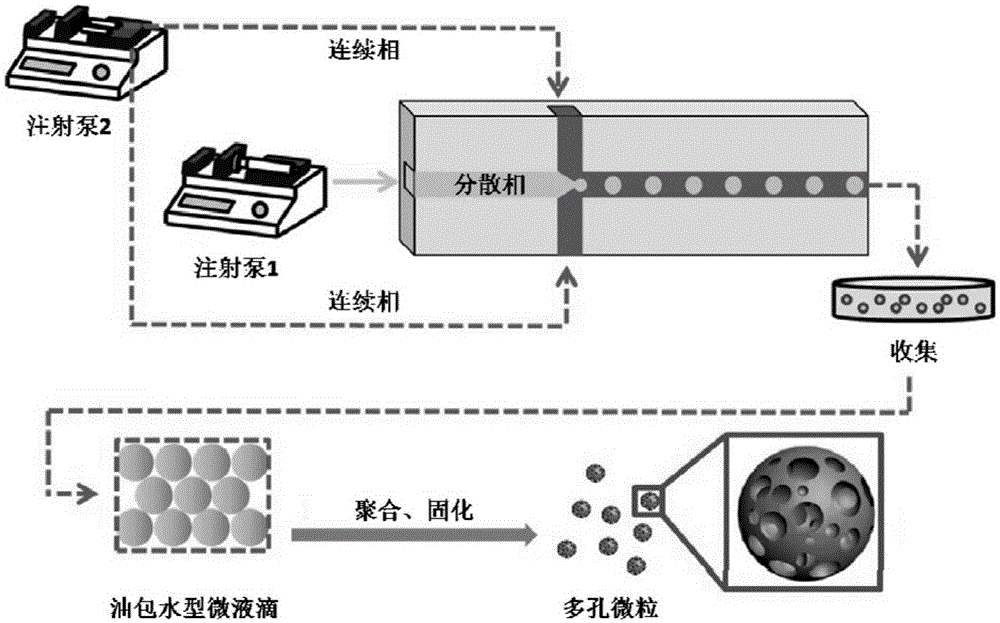

[0079] Such as figure 2 As shown, hydrogen peroxide solution (hydrogen peroxide 10mL, surfactant F-127 (Sigma-AldrichCo.LLC.) 0.1g) and 1,6-hexanediol diacrylate solution (1,6-hexanediol diacrylate 10g, polyglycerol ricinoleate 0.5g, photoinitiator HMPP (Shanghai Aladdin Biochemical Technology Co., Ltd.) 0.1g) mixed and stirred at a high speed in a volume ratio of 1:2, the stirring speed was 25000rpm, and the stirring time was 3 minutes. A dispersed phase solution was obtained; a glycerol solution (2 g of glycerol, 40 mL of deionized water, and 70.4 g of surfactant F-127) added with surfactant F-127 was used as a continuous phase solution. Take 10 mL of the above-mentione...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com