Gentle type yellow mustard sauce easy to smear and preparation method thereof

A yellow mustard and soft technology, applied in the direction of food science, etc., can solve the problems of pungent flavor weakening the irritating flavor of allyl isothiocyanate, low degree of hydrolysis, and large degree of influence, so as to increase the acceptability, Avoid the inactivation of enzymes, the effect of mild taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

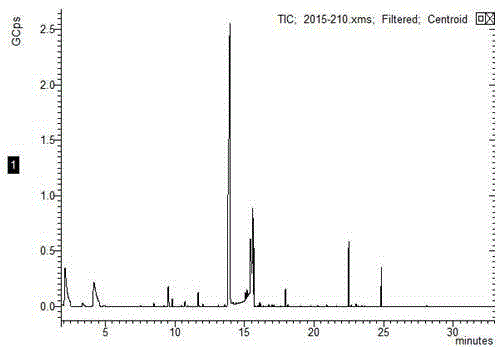

Image

Examples

Embodiment 1

[0033] Example 1 Lemony Mustard Dressing

[0034] Pretreatment of yellow mustard seeds: select high-quality mustard seeds with large light yellow particles and go through winnowing to remove impurities, and activate them in a water bath at 37°C for 20-30h. Then use the grinder to add ice chips, control the temperature of the abrasive at 5-15°C, and carry out preliminary crushing of the yellow mustard seeds, and then carry out airflow ultrafine grinding of the yellow mustard coarse powder, the fineness is more suitable for 60-80 mesh, The process parameters are: working pressure 0.6-0.8MPa, sorting frequency 20-30Hz, crushing 1-2 times;

[0035] Weigh raw materials and additives according to the following parts by weight: yellow mustard powder: 20, white vinegar: 8, salt: 3, white sugar: 3, lactose: 2, water: 65, lemon juice: 30, edible oil: 5, ginger powder : 0.1, Modified Starch: 4, Xanthan Gum: 0.4, White Pepper: 0.1, Soy Protein Powder: 0.5, Beta-Cyclodextrin: 2, Sorbitol:...

Embodiment 2

[0037] Example 2 honey mustard sauce

[0038] Pretreatment of yellow mustard seeds: select high-quality mustard seeds with large light yellow particles and go through winnowing to remove impurities, and activate them in a water bath at 37°C for 20-30h. Then use the grinder to add ice chips, control the abrasive temperature at 5-15°C, and carry out preliminary crushing of the yellow mustard seeds, and then carry out airflow ultrafine grinding of the yellow mustard coarse powder, the fineness is more suitable for 60-80 mesh, The process parameters are: working pressure 0.6-0.8MPa, sorting frequency 20-30Hz, crushing 1-2 times;

[0039] Weigh raw materials and additives according to the following weights: yellow mustard powder: 20, white vinegar: 8, salt: 3, white sugar: 3, lactose: 2, water: 65, honey: 50, edible oil: 5, ginger powder: 0.1 , Modified Starch: 4, Xanthan Gum: 0.4, White Pepper: 0.1, Soy Protein Powder: 0.5, β-Cyclodextrin: 2, Sorbitol: 8, Ascorbic Acid: 0.2, Glyc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com