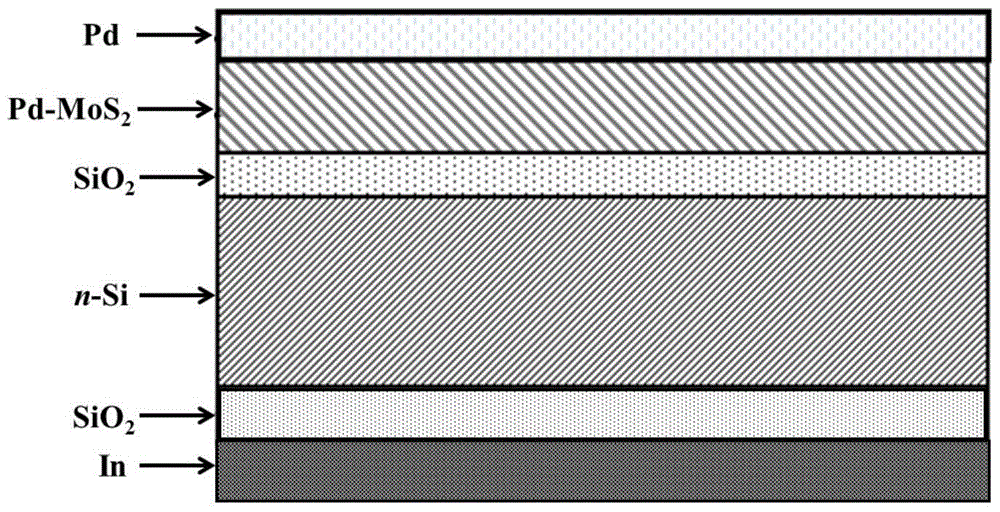

A pd-mos 2 Heterojunction photovoltaic solar cell device and preparation method thereof

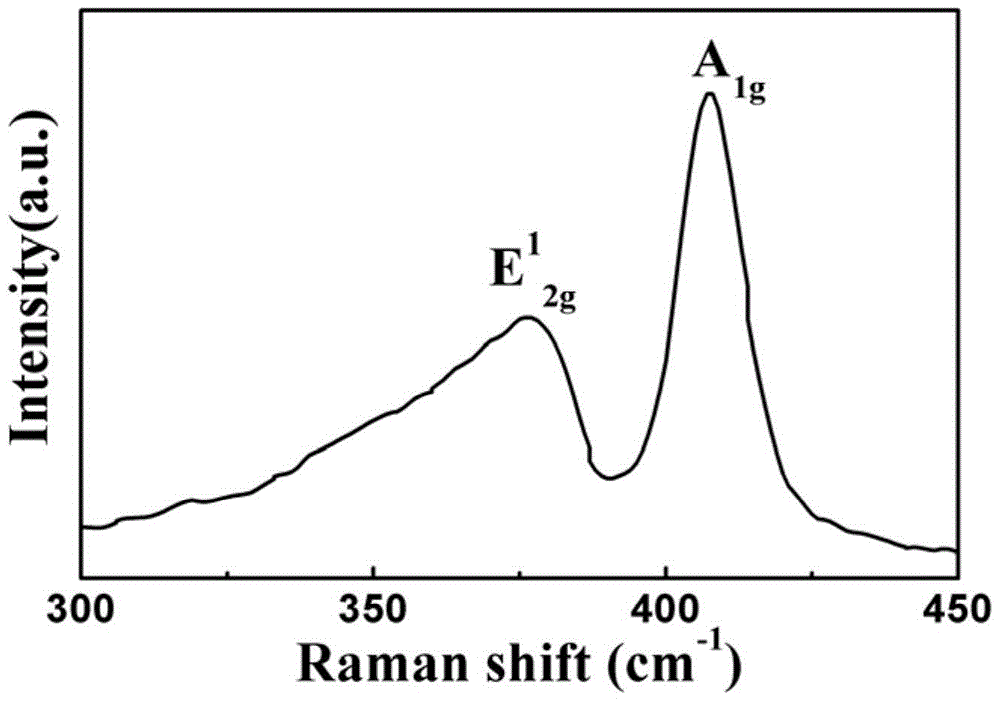

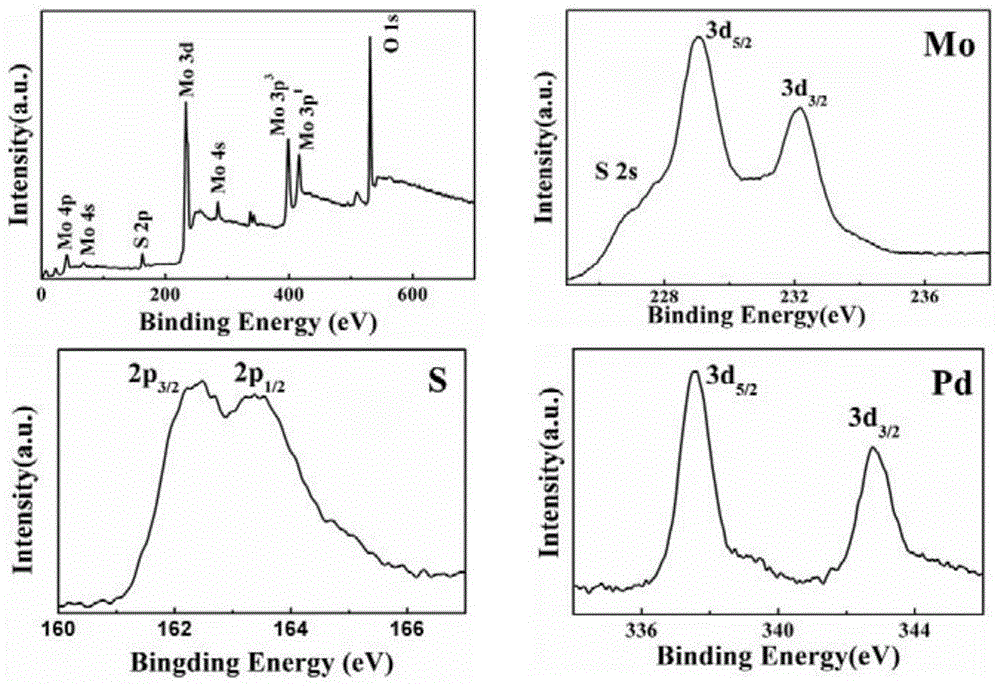

A solar cell, pd-mos2 technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of improving the axial conductivity of MoS2, not adopting effective technical methods, and low short-circuit current density, etc., to achieve good thermal stability and chemical stability, improved photoconversion efficiency, and reduced defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The preparation method is as follows:

[0063] The first step, Pd-MoS 2 Target preparation steps

[0064] According to the number of moles, take 1 part of Pd metal particles with a purity of 99.99% or more, and MoS with a purity of 99.9% or more 2 99 parts of granules, blended and ground into a ball mill until the particle size is 500-800 mesh powder;

[0065] Put the powder obtained by grinding into the mold of the tablet press, and place it on the tablet press. The pressure of the tablet press is 20-25MPa, the pressing time is 1 hour, and it is pressed into a cylindrical shape with a thickness of 3-5mm and a diameter of 60mm. target;

[0066] The second step, silicon substrate surface passivation step

[0067] Select an n-type Si single crystal substrate with a resistivity of 1-10 Ω cm and a crystal plane orientation of (100) plane, and ultrasonically clean it in alcohol, acetone and deionized water for 180 s in sequence;

[0068] Take it out and place it in a hy...

Embodiment 2

[0081] (Explanation: This embodiment is a comparative example, and the target material used is pure MoS 2 target. That is, in the preparation process of the target, Pb metal is not used for MoS 2 for doping)

[0082] The first step, pure MoS 2 Target preparation steps

[0083] Take MoS with a purity of more than 99.9% 2 Particles are ground into a ball mill until the particle size is 500-800 mesh powder;

[0084] Put the powder obtained by grinding into the mold of the tablet press, and place it on the tablet press. The pressure of the tablet press is 20-25MPa, the pressing time is 1 hour, and it is pressed into a cylindrical shape with a thickness of 3-5mm and a diameter of 60mm. target;

[0085] All the other are the same as in Example 1.

[0086] Product performance test results:

[0087] After testing, at 30mWcm -2 Under white light conditions, the prepared MoS 2 The photoexcited current density of the heterojunction photovoltaic solar cell device is 3.5mAcm -2 ...

Embodiment 3

[0089] The first step, Pd-MoS 2 Target preparation steps

[0090] According to the number of moles, take 0.5 part of Pd metal particles with a purity of 99.99% or more, and MoS with a purity of 99.9% or more 2 99.5 parts of granules, blended and ground into a ball mill to a powder with a particle size of 500-800 mesh;

[0091]Put the powder obtained by grinding into the mold of the tablet press, and place it on the tablet press. The pressure of the tablet press is 20-25MPa, the pressing time is 1 hour, and it is pressed into a cylindrical shape with a thickness of 3-5mm and a diameter of 60mm. target;

[0092] All the other are the same as in Example 1.

[0093] Product performance test results:

[0094] After testing, at 30mWcm -2 Under white light conditions, the prepared Pd-MoS 2 The photoexcited current density of the heterojunction photovoltaic solar cell device is 5.2mAcm -2 , open circuit voltage 0.33V, conversion efficiency 2.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com