Preparation method of sulfur dioxide, carbon dioxide and epoxide copolymer

An epoxy compound and carbon dioxide technology, which is applied in the field of thermoplastic and degradable polymer polymer material preparation, can solve the problems of never seen ternary copolymerization of carbon dioxide and epoxy compound, harsh preparation conditions, complicated preparation process, etc., and achieve product structure. The effect of good regularity, simple preparation method and less catalyst dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

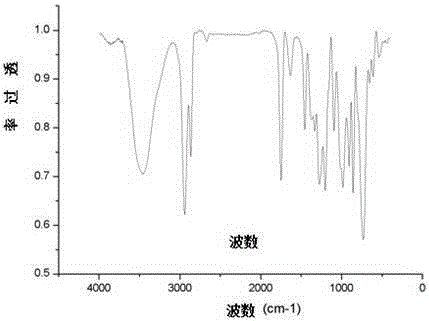

Image

Examples

Embodiment 1

[0025] (1) Add 20mL of epoxycyclohexane and 118.6mg of SalenCr into a 50ml autoclave Ⅲ Cl catalyst and 59.3 mgPPNCl;

[0026] (2) Introduce 99.0% nitrogen gas into the sealed autoclave, repeat nitrogen gas twice, and then in turn introduce sulfur dioxide with a purity of 99.0% and carbon dioxide with a purity of 99.0%, sulfur dioxide and carbon dioxide into the autoclave The molar ratio is 1:4;

[0027] (3) When the pressure reaches 0.5MPa, close the inlet and outlet valves of the high-pressure reactor, set the speed at 280r / min, the temperature at 50°C, and the reaction time at 6h;

[0028] (4) Use chloroform to dissolve the product obtained after the reaction, add hydrochloric acid methanol solution (volume ratio, methanol / hydrochloric acid = 6) for precipitation, obtain an amber precipitate after filtration, wash with methanol 3 times, and place the washed precipitate In a vacuum drying oven, vacuum-dry at room temperature for 8 hours to obtain a terpolymer of sulfur diox...

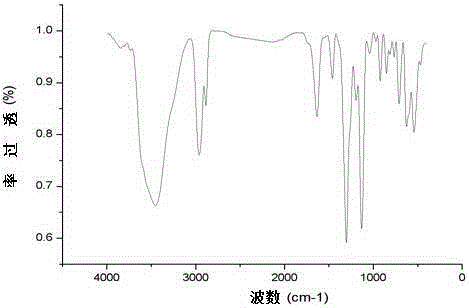

Embodiment 2

[0030] (1) Add 30mL of epoxycyclohexane and 177.9mg of SalenCr to a 50ml autoclave Ⅲ Cl catalyst and 44.5 mgPPNCl;

[0031] (2) Introduce 99.0% nitrogen gas into the sealed autoclave, repeat nitrogen gas three times, and then in turn into the autoclave with 99.0% purity of sulfur dioxide and 99.0% carbon dioxide, the mole of sulfur dioxide and carbon dioxide The ratio is 1:4;

[0032] (3) When the pressure reaches 1MPa, close the inlet and outlet valves of the high-pressure reactor, set the speed at 280r / min, the temperature at 60°C, and the reaction time at 8h;

[0033] (4) Use chloroform to dissolve the product obtained after the reaction, add hydrochloric acid methanol solution (volume ratio, methanol / hydrochloric acid = 6) for precipitation, obtain an amber precipitate after filtration, wash with methanol 4 times, and place the washed precipitate In a vacuum drying oven, vacuum-dry at room temperature for 12 hours to obtain a terpolymer of sulfur dioxide, carbon dioxide ...

Embodiment 3

[0035] (1) Add 20mL of epoxycyclohexane and 59.3mg of SalenCr into a 50ml autoclave Ⅲ Cl catalyst and 29.7 mgPPNCl;

[0036] (2) Introduce 99.0% nitrogen gas into the sealed autoclave, repeat nitrogen gas three times, and then in turn into the autoclave with 99.0% purity of sulfur dioxide and 99.0% carbon dioxide, the mole of sulfur dioxide and carbon dioxide The ratio is 1:4;

[0037](3) When the pressure reaches 2MPa, close the inlet and outlet valves of the high-pressure reactor, set the speed at 280r / min, the temperature at 70°C, and the reaction time at 10h;

[0038] (4) Use chloroform to dissolve the product obtained after the reaction, add hydrochloric acid methanol solution (volume ratio, methanol / hydrochloric acid = 6) for precipitation, obtain an amber precipitate after filtration, wash with methanol 4 times, and place the washed precipitate In a vacuum drying oven, vacuum dry at room temperature for 24 hours to obtain a terpolymer of sulfur dioxide, carbon dioxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com