Stable curing method of arsenic sulfide waste slag

一种固化方法、硫化砷的技术,应用在化学仪器和方法、固体废物的清除、运输和包装等方向,能够解决处理成本高、养护时间长、不利效率的等问题,达到处理效率高、养护时间短、操作简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

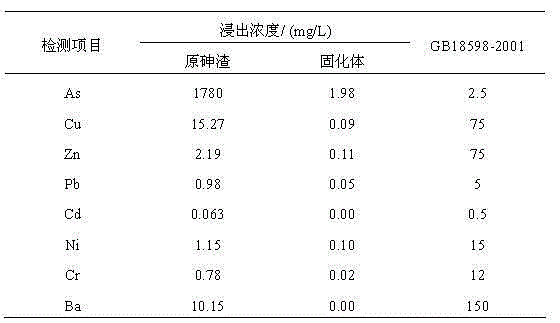

Embodiment 1)

[0025] The strongly acidic arsenic sulfide waste slag treated in this example comes from the sulfuric acid production workshop. According to the "Identification Standard for Hazardous Waste Corrosion Identification" (GB5085.1-2007), the pH value of the waste leaching solution is 1.2; Ethyl dithiocarbamate silver spectrophotometry" (GB / T15555.3-1995) measured the leaching concentration of arsenic as 1780mg / L.

[0026] The stable solidification method of the strongly acidic arsenic sulfide waste residue of the present embodiment comprises the following steps:

[0027] ①Weigh 50g of strong acid arsenic sulfide slag to be treated, add 50g of heavy metal sludge with a moisture content of 50% to it, stir for 40 minutes, and the material after stirring is muddy. The mass ratio of strongly acidic arsenic sulfide slag to heavy metal sludge is 1:1.

[0028] The heavy metal sludge is heavy metal-containing sludge produced after wastewater treatment in industries such as metallurgy, elec...

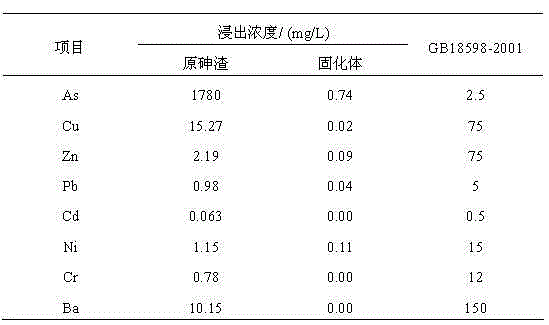

Embodiment 2)

[0042] The stable solidification method of the strongly acidic arsenic sulfide waste residue of the present embodiment is the same as embodiment 1 except that:

[0043] In step ①, add 75 g of heavy metal sludge with a moisture content of 85% to 50 g of strongly acidic arsenic sulfide slag, and stir for 20 minutes. The mass ratio of strongly acidic arsenic sulfide slag to heavy metal sludge is 1:1.5.

[0044] Step 2. Add 60g of calcium hydroxide powder to the muddy material obtained in step 1. After stirring for 20 minutes, all the yellow substances in the muddy material disappear and become slightly black. The mass ratio of strongly acidic arsenic sulfide waste residue to calcium hydroxide powder is 1:1.2.

[0045] Step 3. Add 25g of yellow sand and 25g of cement to the slightly black material obtained after stirring in step 2.

[0046] According to the "Identification of Toxic Substance Content in Hazardous Waste Identification Standards" (GB5085.6-2007), the original stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com