Preparation method and application of fresh-cut fruit and vegetable antistaling agent

A fruit and vegetable preservative and fresh-cut technology, which is applied to the preparation field of fresh-cut fruit and vegetable preservatives, can solve the problems of a pressurized reaction device, increased cost, and is not suitable for popularization and application, and achieves a simple formula, low cost and wide application range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of fresh-cut fruit and vegetable preservative comprises the following steps:

[0034] (1) adding chitosan to a pH value of 4.5 and a concentration of 0.1mol / L in acetate buffer solution, the concentration of chitosan in the resulting mixed solution is 10g / L, and the swelling is overnight; the chitosan The degree of deacetylation is 80%, and the viscosity average molecular weight is 3.0×10 5 Da;

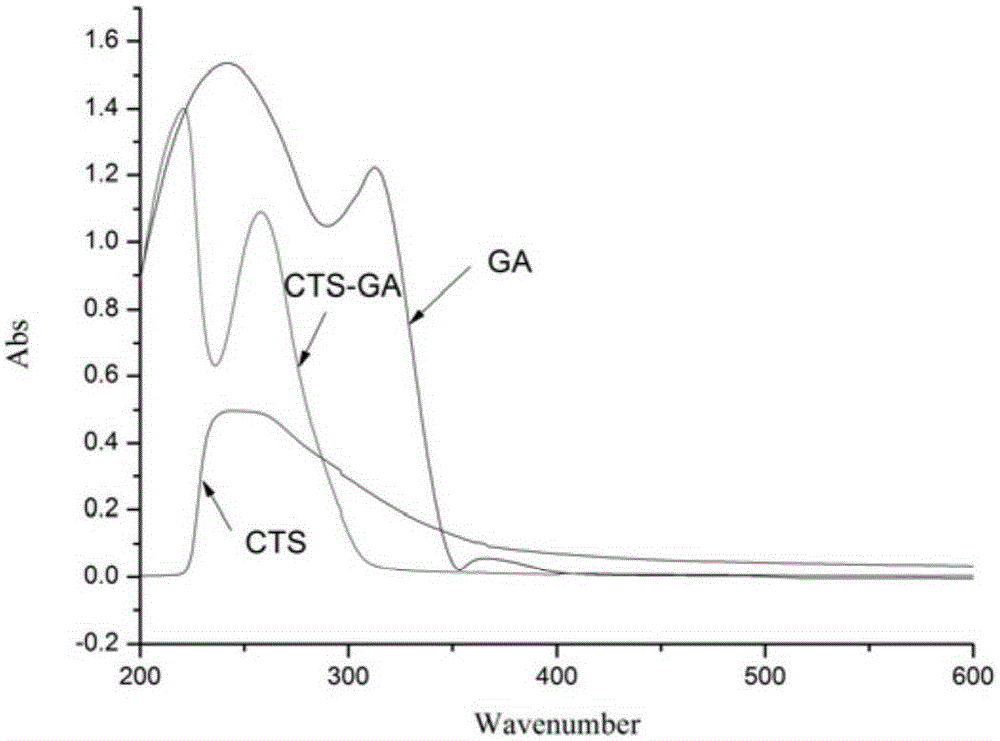

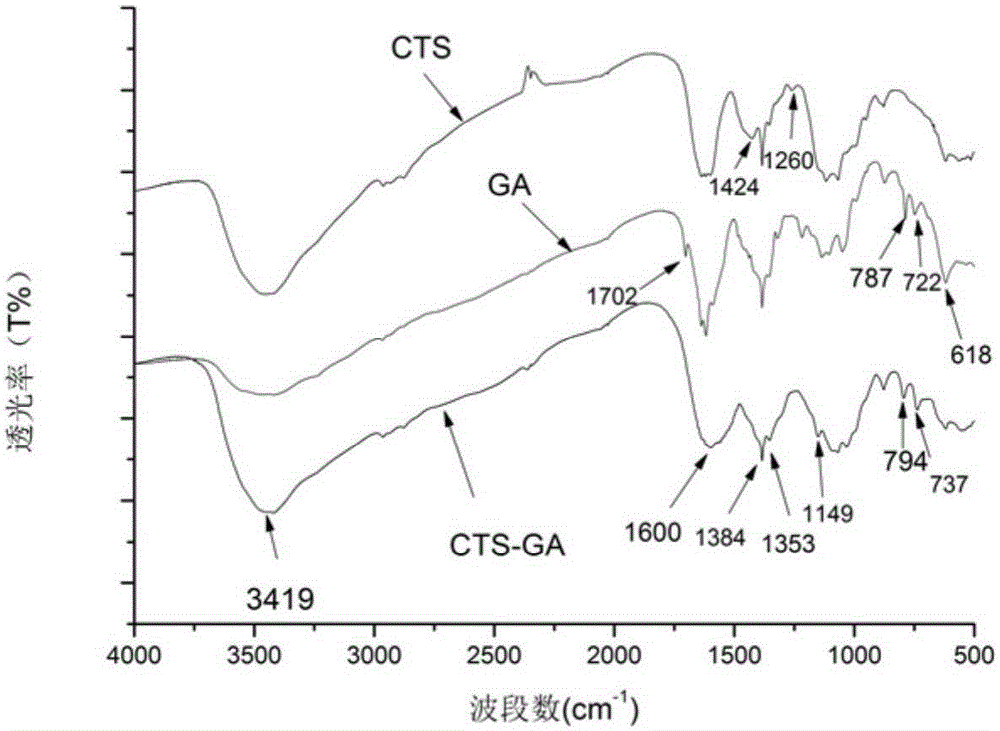

[0035] (2) First add gallic acid in the above mixed solution, the concentration of gallic acid is 28g / L, stir and mix; then add peroxidase, the concentration of peroxidase is 10U / mL, put it into the ultrasonic extractor, set the ultrasonic The power is 200W, the ultrasonic temperature is 45°C, and the ultrasonic time is 90min. After ultrasonication, it is taken out and stirred at room temperature for 5 hours to obtain a chitosan gallic acid derivative, which is freeze-dried to obtain the fresh-cut fruit and vegetable preservative of the present invention...

Embodiment 2

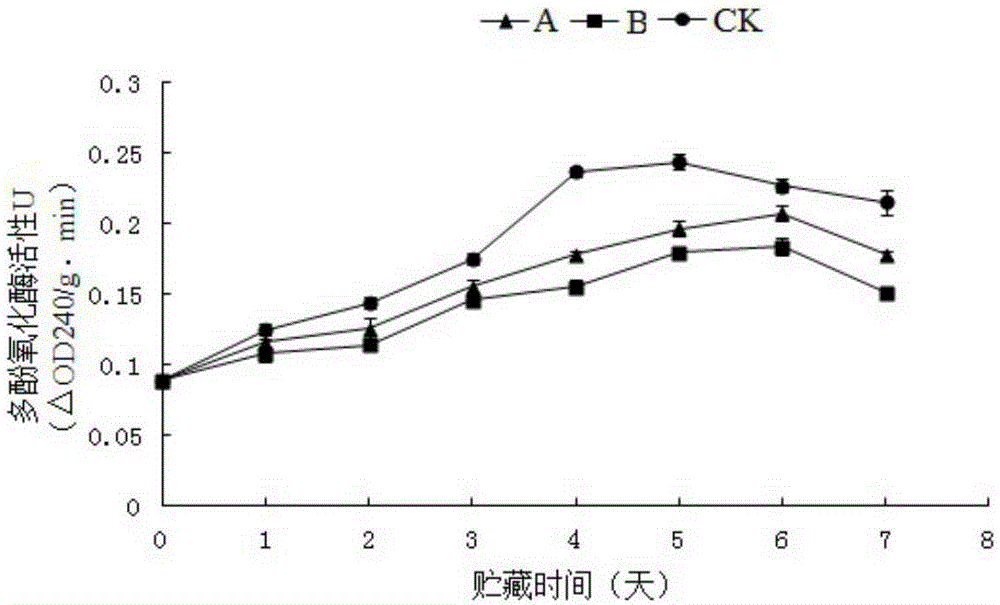

[0039] Embodiment 2. Fresh-cut fruit and vegetable fresh-keeping agent is to the fresh-keeping of fresh-cut apple

[0040] 1. The preparation method of fresh-cut fruit and vegetable preservative A comprises the following steps:

[0041] (1) adding chitosan to a pH value of 4.5 and a concentration of 0.15mol / L in acetate buffer solution, the concentration of chitosan in the resulting mixed solution is 10g / L, and the swelling is overnight; the chitosan The degree of deacetylation is 90%, and the viscosity average molecular weight is 3.0×10 5 Da;

[0042] (2) Add gallic acid and peroxidase respectively in the above mixed solution, the concentration of gallic acid is 30g / L, and the concentration of peroxidase is 10U / mL; at room temperature, stir in a magnetic stirrer for 7 hours to obtain Chitosan gallic acid derivatives are freeze-dried to obtain powdered fresh-cut fruit and vegetable preservative A (hereinafter referred to as preservative A).

[0043] 2. The preparation metho...

Embodiment 3

[0061] Embodiment 3. fresh-cut fruit and vegetable fresh-keeping agent is to the fresh-keeping of fresh-cut pumpkin

[0062] 1. The preparation method of fresh-cut fruit and vegetable preservative A comprises the following steps:

[0063] (1) adding chitosan to a pH value of 3.7 in 0.05mol / L acetate buffer solution, the concentration of chitosan in the mixed solution obtained is 5g / L, and the swelling is overnight; the removal of chitosan The degree of acetylation is 85%, the viscosity average molecular weight is 5.0×10 5 Da;

[0064] (2) Add gallic acid and peroxidase respectively in the above mixed solution, the concentration of gallic acid is 15g / L, and the concentration of peroxidase is 6U / mL; at room temperature, stir in a magnetic stirrer for 8 hours to obtain Chitosan gallic acid derivatives are freeze-dried to obtain powdered fresh-cut fruit and vegetable preservative A (hereinafter referred to as preservative A).

[0065] 2. The preparation method of fresh-cut frui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com