A carbon-coated li 4 ti 5 o 12 ‑tio 2 /sn nanocomposite material and its preparation and application

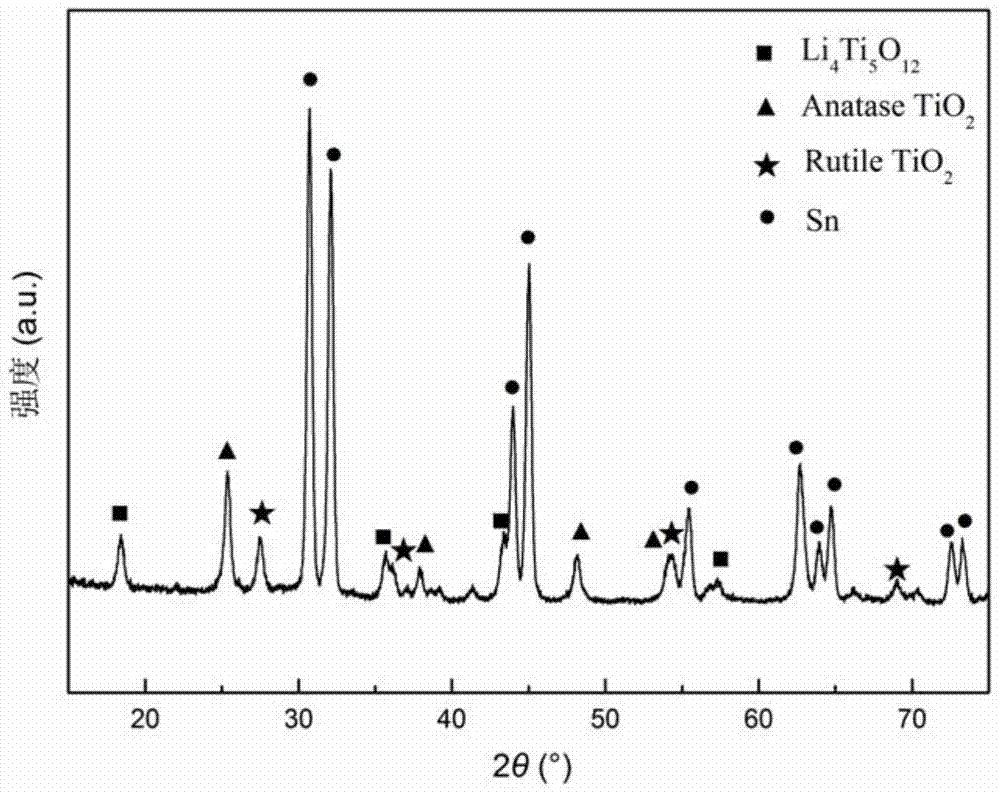

A nanocomposite material, li1.81h0.19ti2o5 xh2o technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of unsatisfactory reversible capacity and cycle stability, Sn nanoparticles Easy agglomeration, unsatisfactory cycle stability and other problems, to achieve the effect of improving electronic conductivity and ion permeability, shortening migration distance, and excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 2.5g P 25 TiO 2 Mix it with 80mL of NaOH solution with a concentration of 10mol / L, stir for 4h, then carry out hydrothermal reaction for 96h, and the hydrothermal temperature is 120°C. After the reaction, the product was added to excess dilute nitric acid with a concentration of 0.1 mol / L and stirred for 0.5 h. After centrifugation, the product was dried at 60° C. to obtain white fluffy titanic acid nanopowder.

Embodiment 2

[0051] 6.5g rutile TiO 2 Mix with 80mL of KOH solution with a concentration of 15mol / L, stir for 5h, and then carry out hydrothermal reaction for 30h, and the hydrothermal temperature is 150°C. After the reaction, the product was added to excess dilute hydrochloric acid with a concentration of 0.8 mol / L and stirred for 12 hours. After suction filtration, the product was dried at 60° C. to obtain white fluffy titanic acid nanopowder.

Embodiment 3

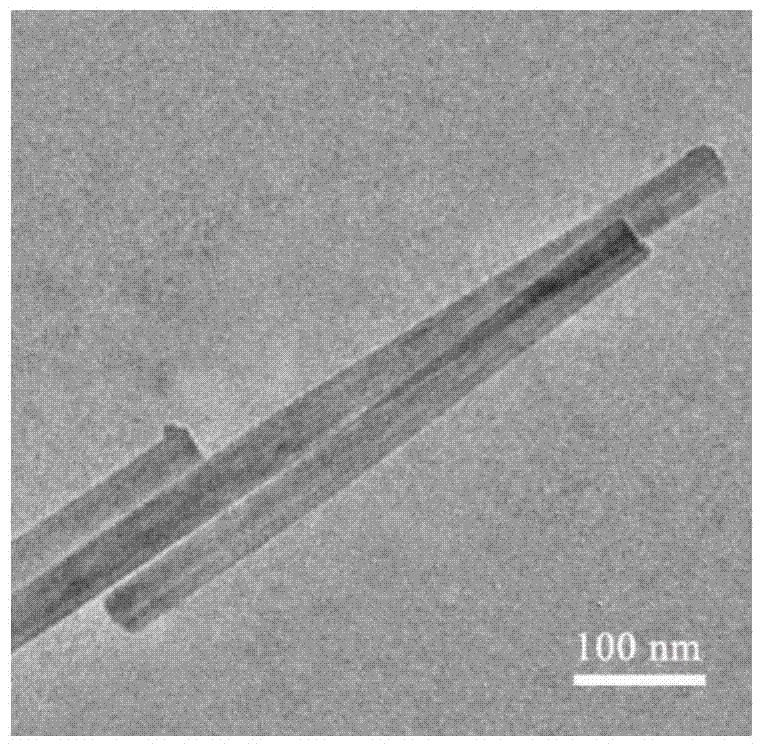

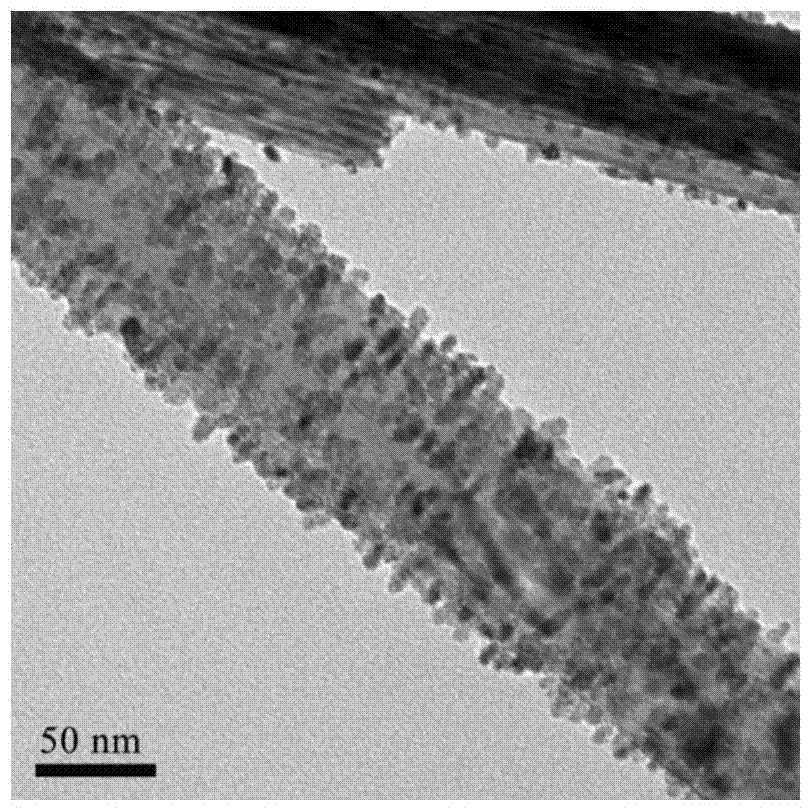

[0053] 9.5g anatase TiO 2 Mix with 80mL of NaOH solution with a concentration of 20mol / L, stir for 3h, then carry out hydrothermal reaction for 72h, and the hydrothermal temperature is 180°C. After the reaction, the product was added to excess dilute hydrochloric acid with a concentration of 0.5 mol / L and stirred for 10 h. After suction filtration, the product was dried at 60° C. to obtain white fluffy titanic acid nanopowder. TEM image of the material see figure 1 .

[0054] Li 1.81 h 0.19 Ti 2 o 5 ·xH 2 O / SnO 2 Precursor preparation

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com