Pressing type travel switch resisting severe environment

A travel switch, harsh environment technology, applied in the direction of contact operating parts, etc., to achieve the effect of compact structure, ensuring displacement accuracy, and simplifying the structure of static contact springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

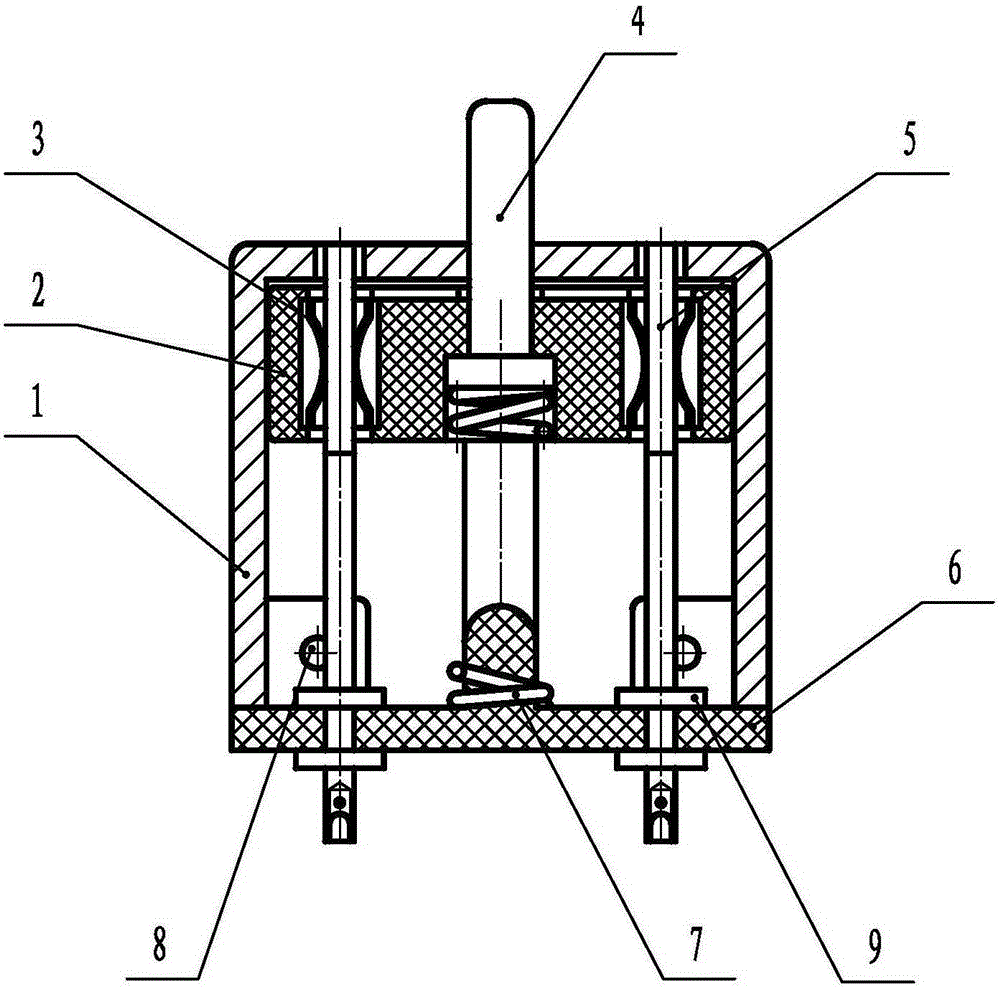

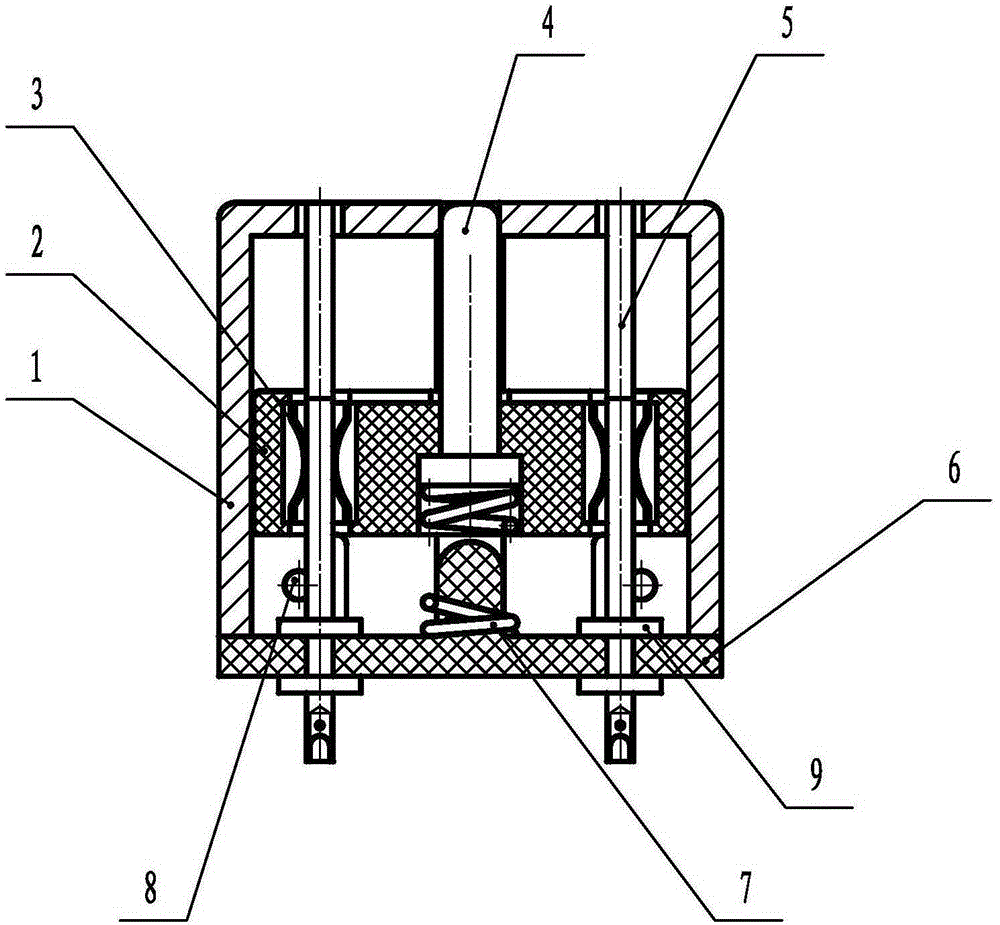

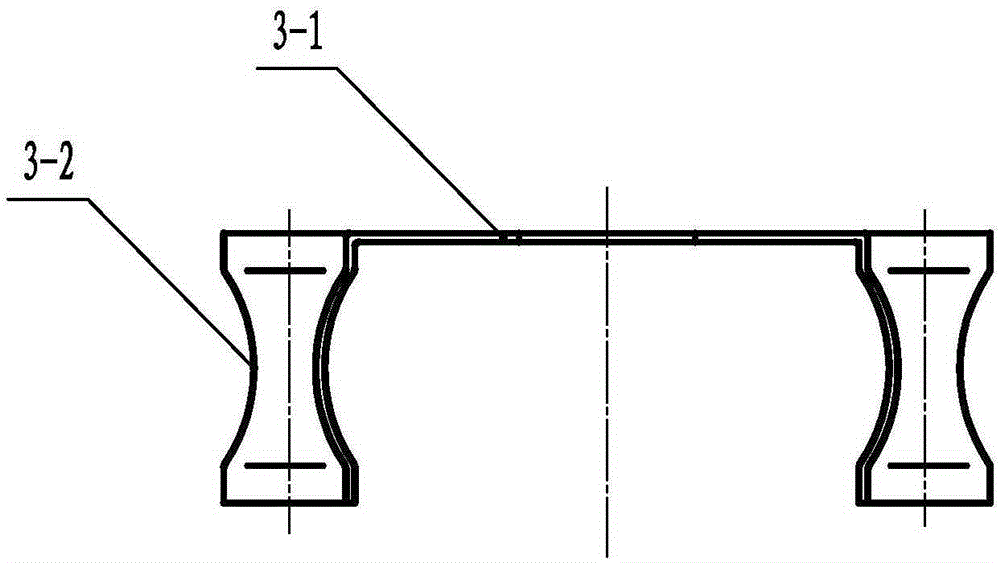

[0035] A push-type travel switch resistant to harsh environments, such as figure 1 with 2 As shown, it consists of a housing 1, a drive body 2 assembly, a base assembly and a compression spring 7.

[0036]The base assembly includes a base body 6 and at least one set of contact rods 5 . The base body 6 is plate-shaped, and the center position of its upper surface is provided with a positioning boss, which is used as the positioning boss of the stage clip 7 of the push-type travel switch to fix and position the lower end of the stage clip 7 . In addition, the upper surface of the base body 6 is symmetrically provided with two or more limiting protrusions 9 for limiting the downward stroke of the driving body 2 . Each group of 5 contact rods is composed of 2 contact rods 5. The 2 contact rods 5 are located on both sides of the positioning boss, and vertically penetrated and fixed in the base body 6, and are integrally injected or molded. The insert molding process makes the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com