A kind of anti-ultraviolet finishing agent and preparation method thereof

An anti-ultraviolet and finishing agent technology, which is applied in fiber treatment, plant fiber, textiles and papermaking, etc., can solve the problems of mechanical and other performance degradation, affect the anti-ultraviolet effect, and poor particle compatibility, so as to prevent interface defects and avoid Easy to aggregate and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

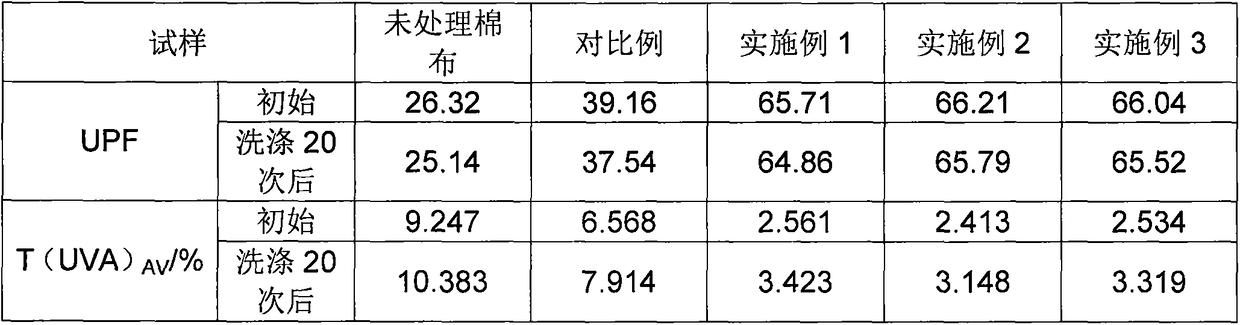

Examples

preparation example Construction

[0011] Wherein, the preparation method of described nano titanium dioxide graft copolymer comprises the following steps

[0012] a. Weigh a certain amount of nano-titanium dioxide particles and silane coupling agent in absolute ethanol, stir evenly, disperse ultrasonically for 10 minutes, heat in a water bath to 50-70°C for 5 hours, dry at 80°C and grind to obtain modification Nano titanium dioxide particles;

[0013] b. Add the modified nano-titanium dioxide particles to a certain concentration of polymerizable emulsifier aqueous solution, stir evenly and ultrasonically disperse for 10 minutes, add the initiator aqueous solution when the water bath is heated to 70-80°C, add dropwise the acrylate monomer and the remaining initiator After the dropwise addition, the reaction was continued for 5 hours, cooled naturally to room temperature, and filtered to obtain a uniform and stable nano-titanium dioxide graft copolymer.

[0014] In the nano-titanium dioxide graft copolymer, in ...

Embodiment 1

[0032] (1) Preparation of Nano Titanium Dioxide Graft Copolymer

[0033] a. Weigh 15 parts of nano-titanium dioxide particles and 2 parts of silane coupling agent in 150 mL of absolute ethanol, stir evenly and disperse ultrasonically for 10 minutes, heat in a water bath to 50°C for 5 hours, dry at 80°C and grind to obtain modification Nano titanium dioxide particles; the silane coupling agent is γ-methacryloxypropyltrimethoxysilane (KH-570).

[0034]b. Add the modified nano-titanium dioxide particles to a solution of 12 parts of polymerizable emulsifier and 300mL of water, stir evenly and then ultrasonically disperse for 10 minutes. When the water bath is heated to 70°C, add 0.5 parts of an aqueous solution of initiator potassium persulfate, dropwise The aqueous solution of 54 parts of acrylate monomer, 14 parts of fluorine-containing monomer and 0.5 part of initiator potassium persulfate, continued to react for 5 hours after the dropwise addition, naturally cooled to room tem...

Embodiment 2

[0042] (1) Preparation of Nano Titanium Dioxide Graft Copolymer

[0043] a. Weigh 17 parts of nano-titanium dioxide particles and 3 parts of silane coupling agent in 200mL of absolute ethanol, stir evenly and then ultrasonically disperse for 10 minutes, heat in a water bath to 60°C for 5 hours, dry at 80°C and grind to obtain modification Nano titanium dioxide particles; the silane coupling agent is vinyltriethoxysilane (KH-151).

[0044] b. Add the modified nano-titanium dioxide particles to a solution of 15 parts of polymerizable emulsifier and 300mL of water, stir evenly and ultrasonically disperse for 10 minutes. When the water bath is heated to 75°C, add 0.5 parts of the aqueous solution of initiator ammonium persulfate, dropwise The aqueous solution of 61 parts of acrylate monomer, 18 parts of fluorine-containing monomer and 0.7 part of initiator ammonium persulfate, continued to react for 5 hours after the dropwise addition, cooled naturally to room temperature, and fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com