A method of pulse reverse electrodeposition thick tungsten coating

A pulse reversal, electrodeposition technology, applied in the field of surface treatment, can solve the problems of uneven surface, low electrodeposition efficiency, uneven coating distribution, etc., to achieve good flatness, increase electrodeposition efficiency, and improve electrodeposition rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. Pretreatment: Use wire cutting to cut low-activation steel plate and tungsten plate into sheet samples, and then use 240#, 500#, 800# sandpaper to polish, then use acetone to ultrasonically clean the surface of the anode and the substrate, and dry spare.

[0032] b. Molten salt preparation: Before the molten salt preparation, sodium tungstate and tungsten trioxide were dried at 250°C for 12 hours. Sodium tungstate and tungsten trioxide with a molar ratio of 3:1 are ground and mixed evenly, then put into a high-purity alumina crucible, heated to 850°C in a crucible resistance furnace, and kept warm for use.

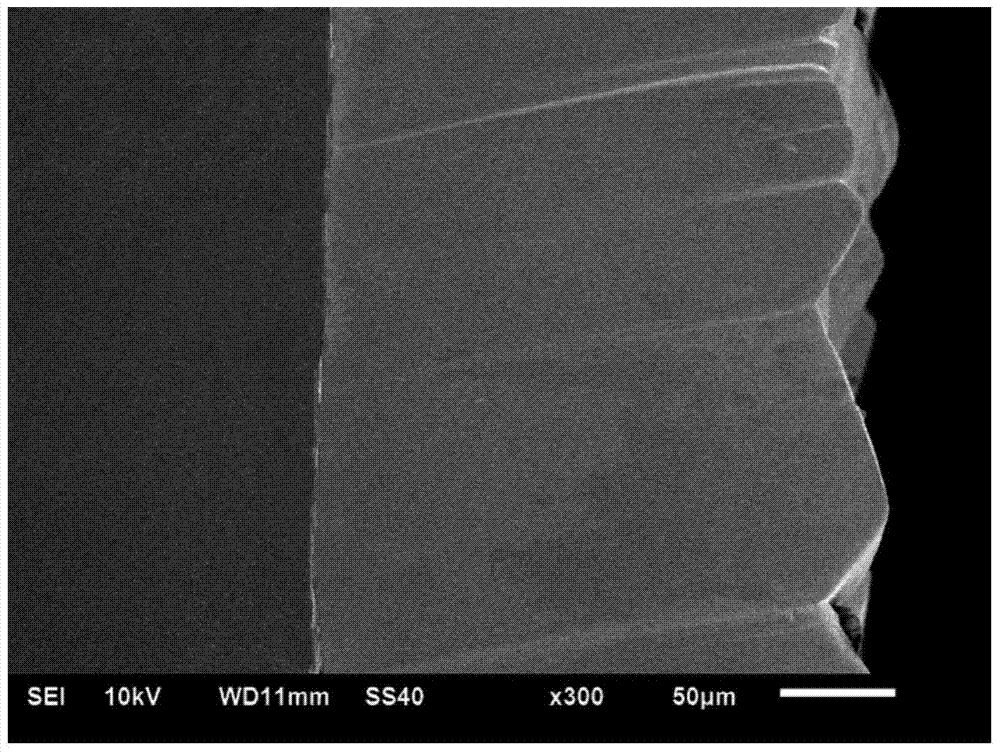

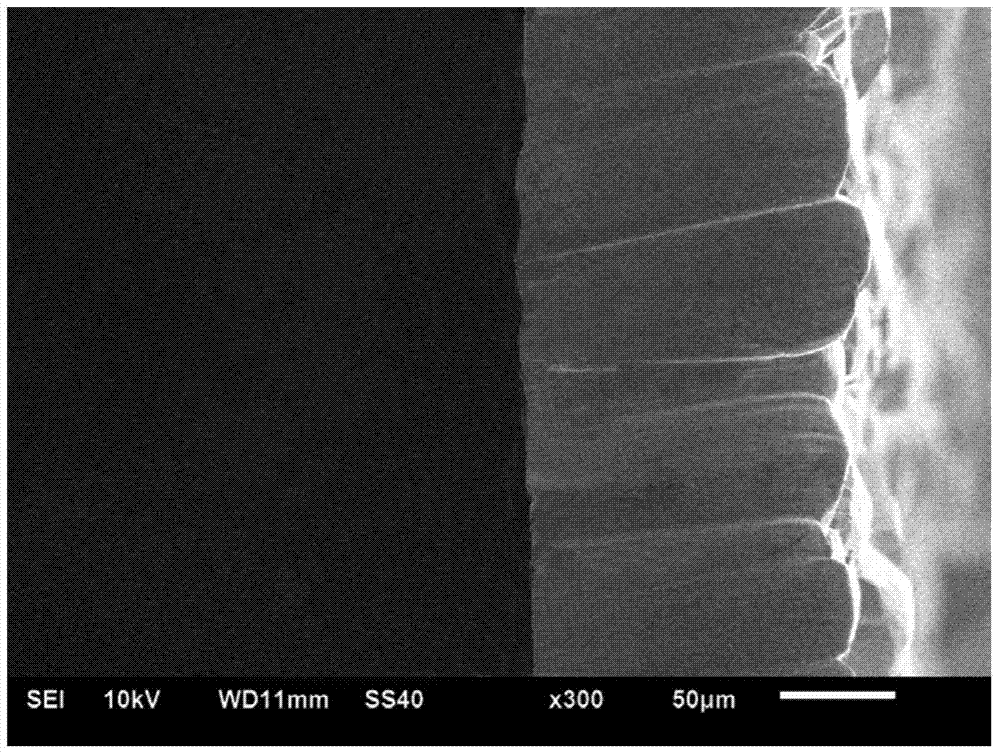

[0033] c. Pulse reverse electrodeposition: connect the treated low-activation steel plate and tungsten plate through platinum wire and put them into molten salt until completely submerged. The low-activation steel plate is used as the cathode and the tungsten plate is used as the anode. Double anodes are used to place the anode and cathode in parallel. The elect...

Embodiment 2

[0040] a. Pretreatment: Use wire cutting to cut low-activation steel plate and tungsten plate into sheet samples, and then use 240#, 500#, 800# sandpaper to polish, then use acetone to ultrasonically clean the surface of the anode and the substrate, and dry spare.

[0041] b. Molten salt preparation: Before the molten salt preparation, sodium tungstate and tungsten trioxide were dried at 250°C for 12 hours. Sodium tungstate and tungsten trioxide with a molar ratio of 3:1 are ground and mixed evenly, then put into a high-purity alumina crucible, heated to 900°C in a crucible resistance furnace, and kept warm for use.

[0042]c. Pulse reverse electrodeposition: connect the treated low-activation steel plate and tungsten plate through platinum wire and put them into molten salt until completely submerged. The low-activation steel plate is used as the cathode and the tungsten plate is used as the anode. Double anodes are used to place the anode and cathode in parallel. The electr...

Embodiment 3

[0048] a. Pretreatment: Use wire cutting to cut low-activation steel plate and tungsten plate into sheet samples, and then use 240#, 500#, 800# sandpaper to polish, then use acetone to ultrasonically clean the surface of the anode and the substrate, and dry spare.

[0049] b. Molten salt preparation: Before the molten salt preparation, sodium tungstate and tungsten trioxide were dried at 250°C for 12 hours. Sodium tungstate and tungsten trioxide with a molar ratio of 3:1 are ground and mixed evenly, then put into a high-purity alumina crucible, heated to 900°C in a crucible resistance furnace, and kept warm for use.

[0050] c. Pulse reverse electrodeposition: connect the treated low-activation steel plate and tungsten plate through platinum wire and put them into molten salt until completely submerged. The low-activation steel plate is used as the cathode and the tungsten plate is used as the anode. Double anodes are used to place the anode and cathode in parallel. The elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com