NaLaMgWO6:xSm<3+> red phosphor powder for LED (Light Emitting Diode), and preparation method thereof

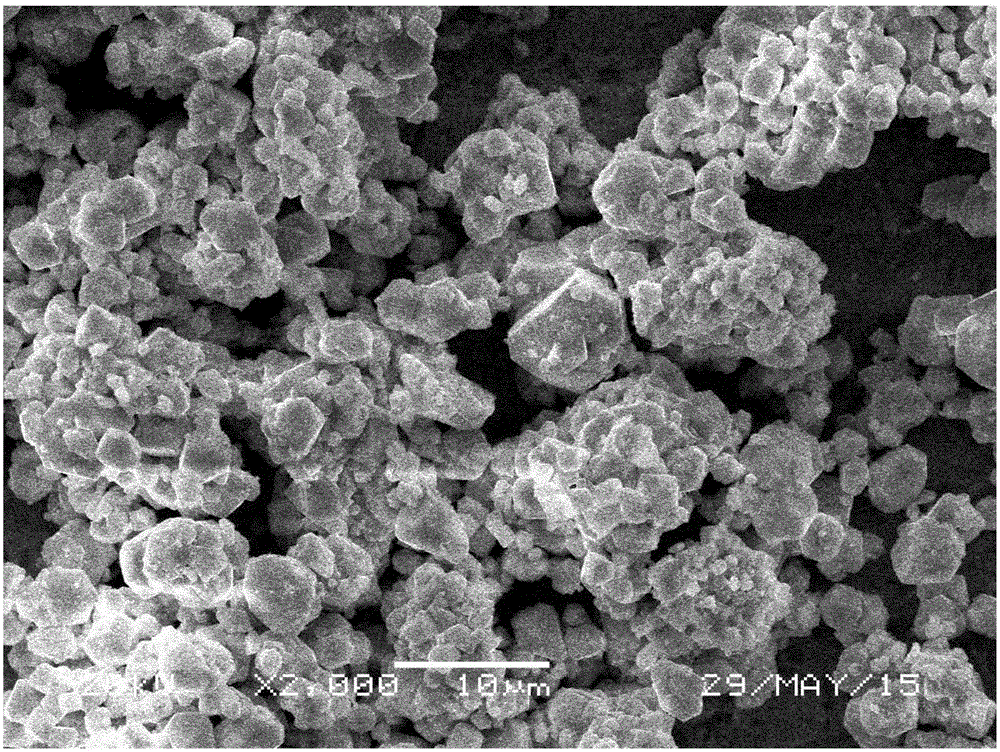

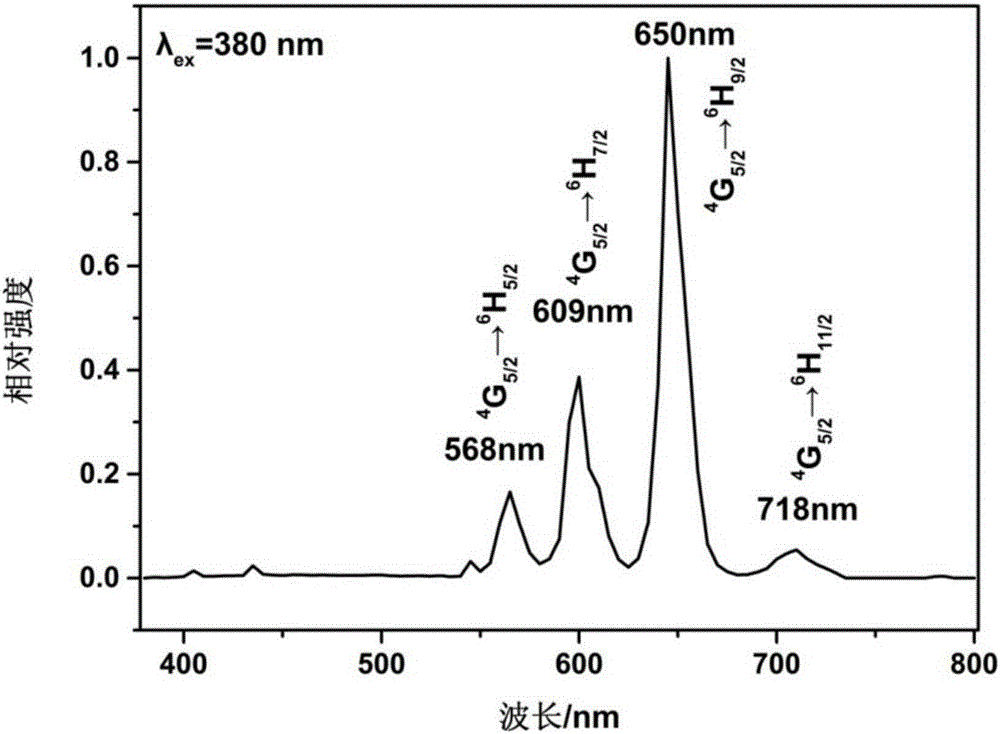

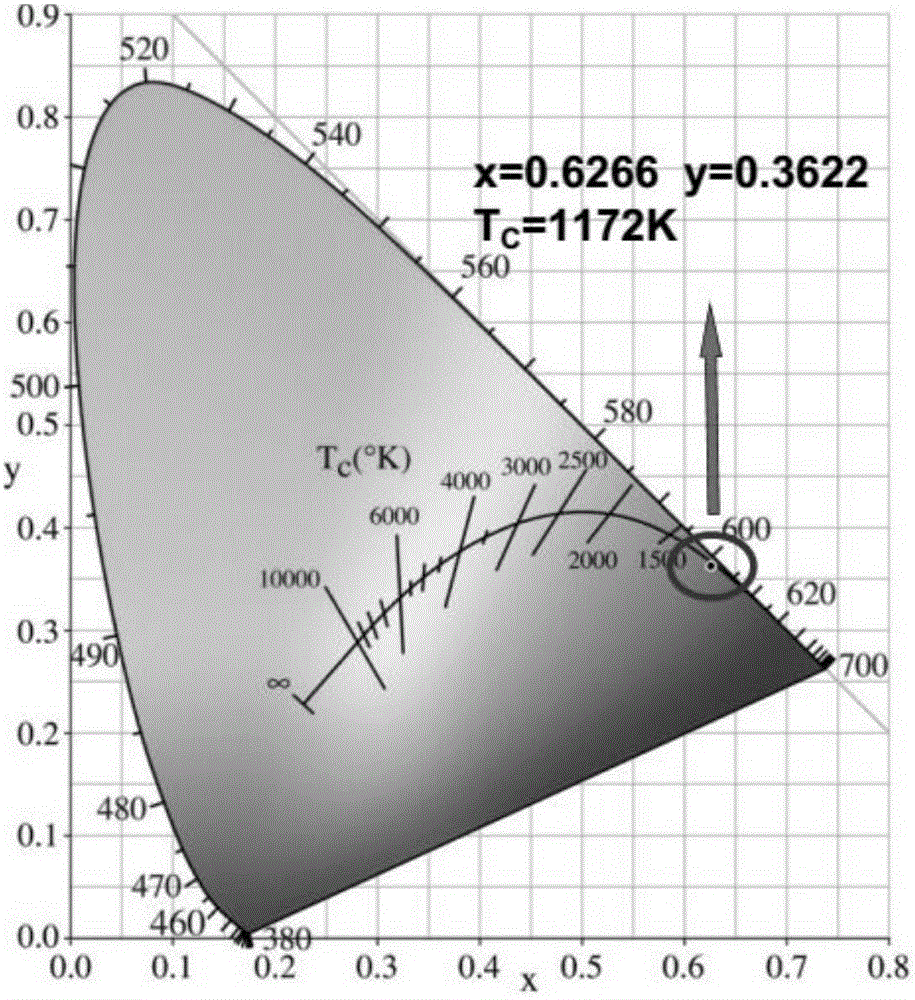

A technology of red fluorescent powder and powder, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of difficulty in obtaining spherical particles with regular shape, weakened luminous efficiency of fluorescent powder, uneven particle size distribution, etc., and achieves the production cycle Short, good crystallization performance, and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) According to the molar ratio of 1.14:1:0.5:1:0.025, weigh NaOH·H 2 O, WO 3 , La 2 o 3 , MgO, Sm 2 o 3 as raw material;

[0029] 2) Put the weighed NaOH·H 2 O is added to the beaker, and an appropriate amount of deionized water is added to it to fully dissolve it, and the NaOH solution and the WO weighed in step 1 3 Put it into the condensing reflux device, keep it warm in a silicone oil bath at 80°C for 6 hours, take it out after cooling to room temperature with the device, dry and grind to obtain powder A;

[0030] 3) The Sm weighed in step 1 2 o 3 Add 10ml of polyvinyl alcohol solution with a concentration of 1%, ultrasonically treat it to make it dispersed evenly, add concentrated nitric acid drop by drop to the dispersion to make Sm 2 o 3 All dissolved (concentrated nitric acid can be slightly excessive), to obtain transparent liquid B;

[0031] 4) the La weighed in step 1 2 o 3 , MgO and the powder A obtained in step 2 are placed in an agate mortar ...

Embodiment 2

[0036]1) According to the molar ratio of 1.18:1:0.5:1:0.025, weigh NaOH·H 2 O, WO 3 , La 2 o 3 , MgO, Sm 2 o 3 as raw material;

[0037] 2) Put the weighed NaOH·H 2 O is added to the beaker, and an appropriate amount of deionized water is added to it to fully dissolve it, and the NaOH solution and the WO weighed in step 1 3 Put it into the condensing reflux device, keep it warm in a silicone oil bath at 75°C for 8 hours, take it out after cooling to room temperature with the device, dry and grind to obtain powder A;

[0038] 3) The Sm weighed in step 1 2 o 3 Add 10ml of polyvinyl alcohol solution with a concentration of 1.5%, ultrasonically treat it to make it disperse evenly, add concentrated nitric acid drop by drop to the dispersion to make Sm 2 o 3 All dissolved (concentrated nitric acid can be slightly excessive), to obtain transparent liquid B;

[0039] 4) the La weighed in step 1 2 o 3 , MgO and the powder A obtained in step 2 are placed in an agate mortar ...

Embodiment 3

[0043] 1) According to the molar ratio of 1.1:1:0.5:1:0.005, weigh NaOH·H 2 O, WO 3 , La 2 o 3 , MgO, Sm 2 o 3 as raw material;

[0044] 2) Put the weighed NaOH·H 2 O is added to the beaker, and an appropriate amount of deionized water is added to it to fully dissolve it, and the NaOH solution and the WO weighed in step 1 3 Put it into the condensing reflux device, keep it warm in a silicone oil bath at 70°C for 10 hours, take it out after cooling to room temperature with the device, dry and grind to obtain powder A;

[0045] 3) The Sm weighed in step 1 2 o 3 Add 10ml of polyvinyl alcohol solution with a concentration of 0.5%, ultrasonically treat it to make it dispersed evenly, add concentrated nitric acid drop by drop to the dispersion to make Sm 2 o 3 All dissolved (concentrated nitric acid can be slightly excessive), to obtain transparent liquid B;

[0046] 4) Put the La2O3 and MgO weighed in step 1 and the powder A obtained in step 2 into an agate mortar and gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com