Interference solar selective heat absorption coating layer

A technology of heat-absorbing coatings and solar energy, applied in solar thermal power generation, solar thermal devices, coatings, etc., can solve problems such as poor stability, attenuation of heat-absorbing performance, and easy oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

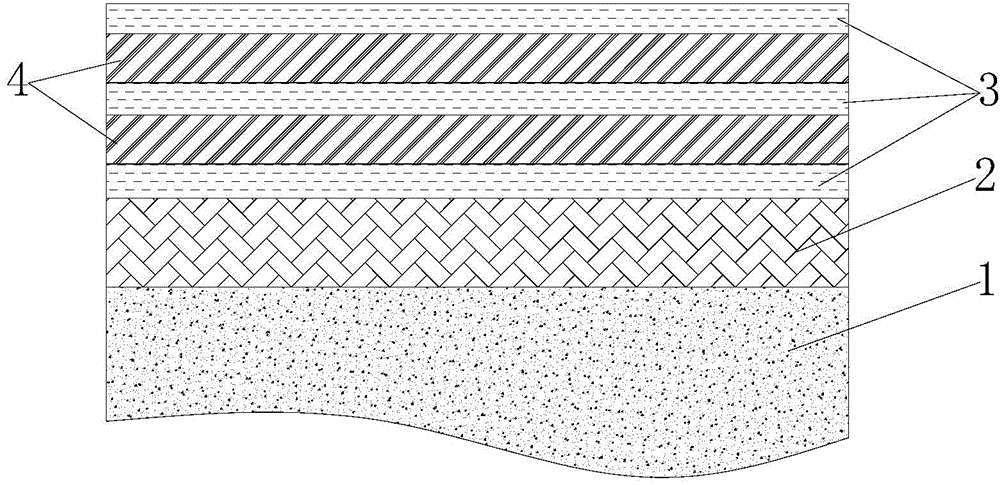

[0017] Choose aluminum as the substrate of the heat-absorbing coating, and prepare 5nm chromium, 40nm silicon nitride, 25nm chromium nitride, 10nm silicon nitride, 15nm chromium nitride and 60nm silicon nitride from the substrate upwards by magnetron sputtering . Among them, silicon nitride is prepared by reactive sputtering of silicon target in nitrogen environment, and chromium nitride is prepared by reactive sputtering of metal chromium target in nitrogen environment. Thus, a blue heat-absorbing coating with excellent performance is obtained. After testing, the coating has an absorptivity of 0.952 and a thermal emissivity of 0.04.

[0018] Such as figure 1 As shown, the aluminum layer is the substrate 1 , the chromium layer is the metal bonding layer 2 , the silicon nitride layer is the transparent medium layer 3 , and the chromium nitride layer is the compound material absorption layer 4 .

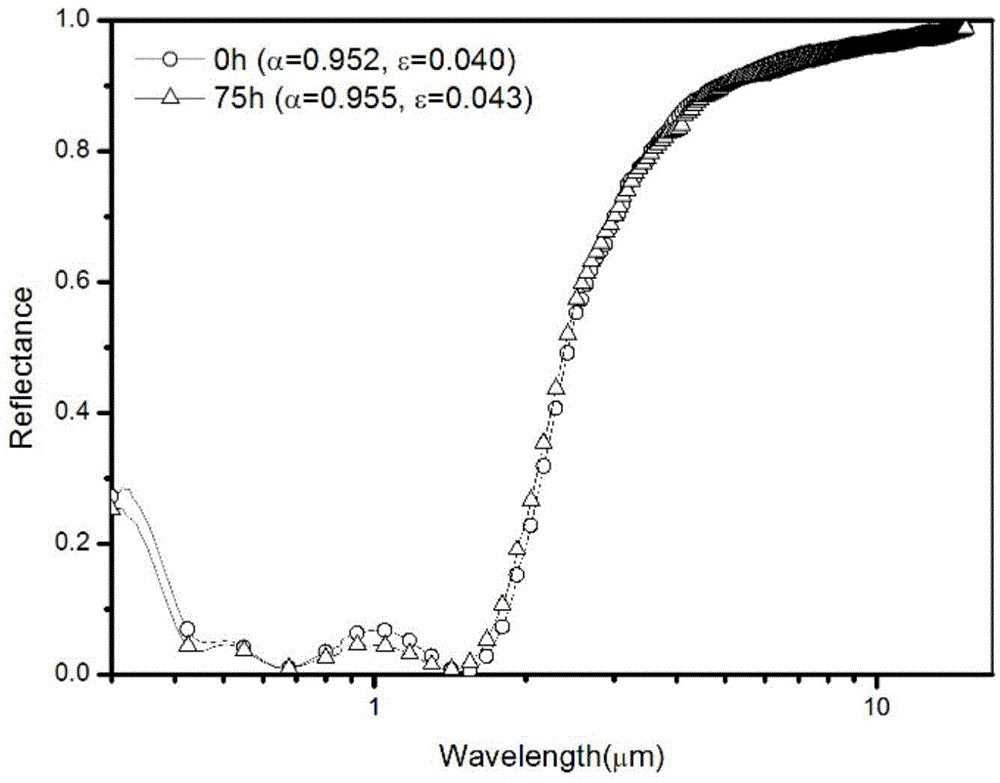

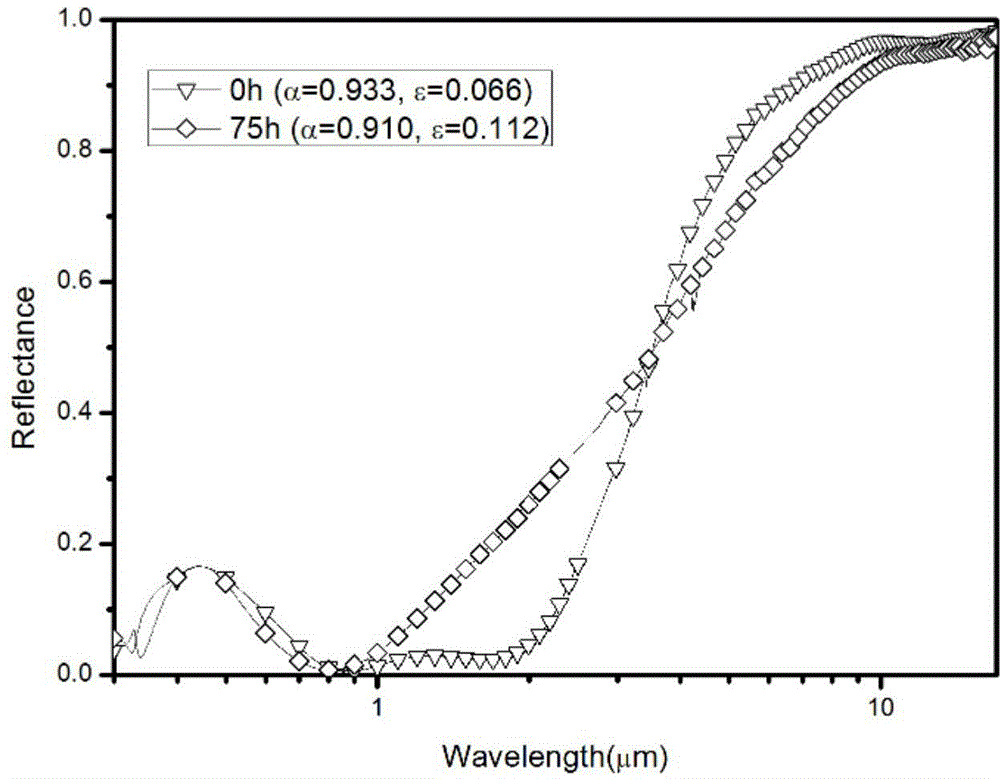

[0019] Such as figure 2 and image 3 As shown, the absorptivity and emissivit...

Embodiment 2

[0021] The aluminum after anodic oxidation and surface treatment is selected as the substrate of the heat-absorbing coating, and a 5nm titanium layer, 40nm silicon nitride, 35nm titanium carbide, 23nm silicon nitride, and 23nm carbon carbide are prepared from the substrate upwards by magnetron sputtering. Titanium and 65nm silicon nitride. Among them, silicon nitride is prepared by reactive sputtering of silicon target in nitrogen environment, and titanium nitride is prepared by reactive sputtering of metal titanium target in nitrogen environment. The obtained heat-absorbing coating is blue, and after testing, the absorptivity is 0.946, and the thermal emissivity is 0.045.

Embodiment 3

[0023] Choose copper as the substrate of the heat-absorbing coating, and prepare 4nm titanium, 26nm titanium nitride, 30nm aluminum nitride, 20nm titanium nitride, 30nm aluminum nitride, 15nm titanium nitride, 24nm aluminum nitride, and 10nm nitrogen from the substrate upwards. TiO, 55nm Aluminum Nitride. Among them, aluminum nitride is prepared by reactive sputtering of aluminum target in nitrogen environment, and titanium nitride is prepared by reactive sputtering of metal titanium target in nitrogen environment. The layer was tested to have an absorptivity of 0.942% and a thermal emissivity of 0.038.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com