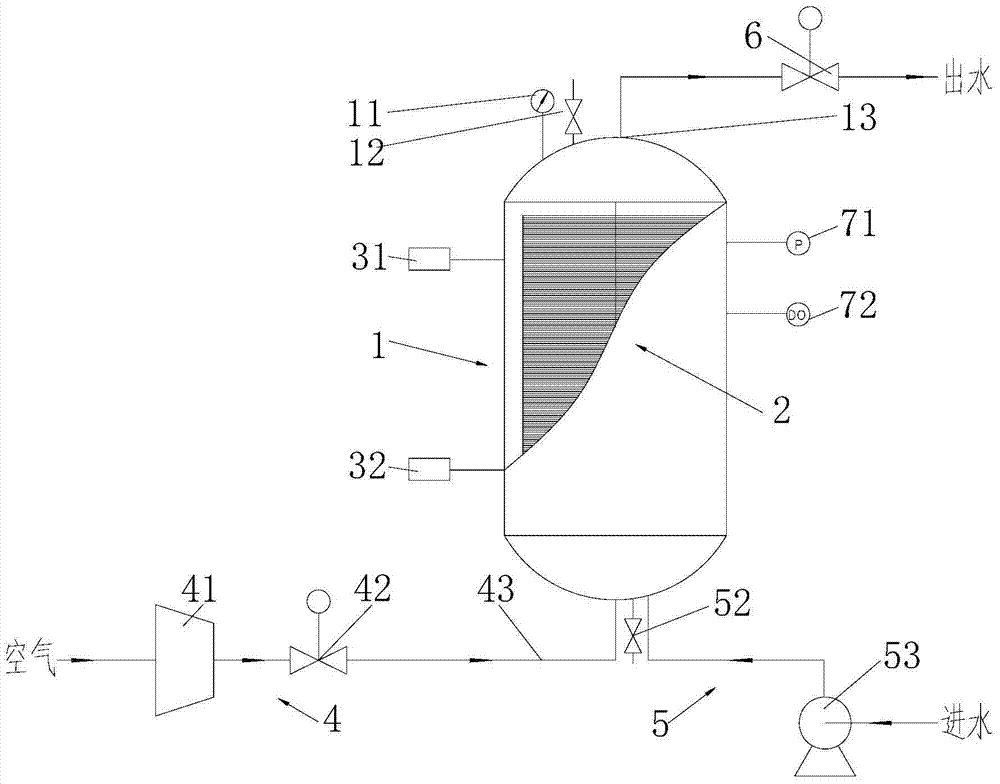

Enhanced electrochemical oxidation wastewater treatment device and treatment method

A technology for oxidizing wastewater and treating device, applied in the direction of sterilization/microdynamic water/sewage treatment, etc., can solve the problems of high operating cost, high energy consumption, low current efficiency, etc., and achieve simple operation, low energy consumption, and current density added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

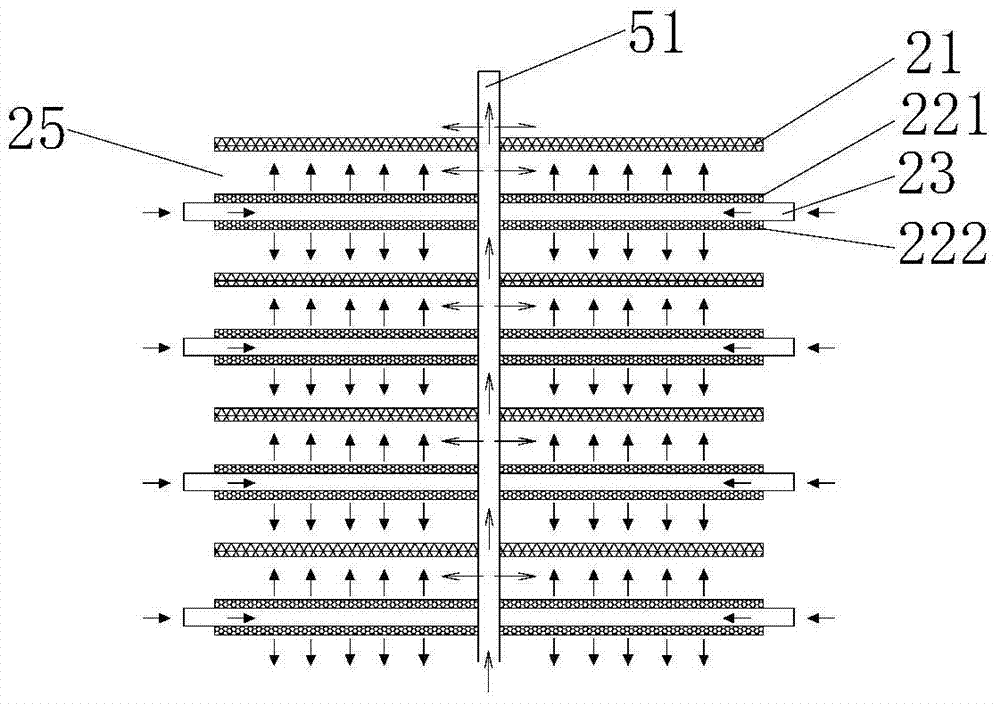

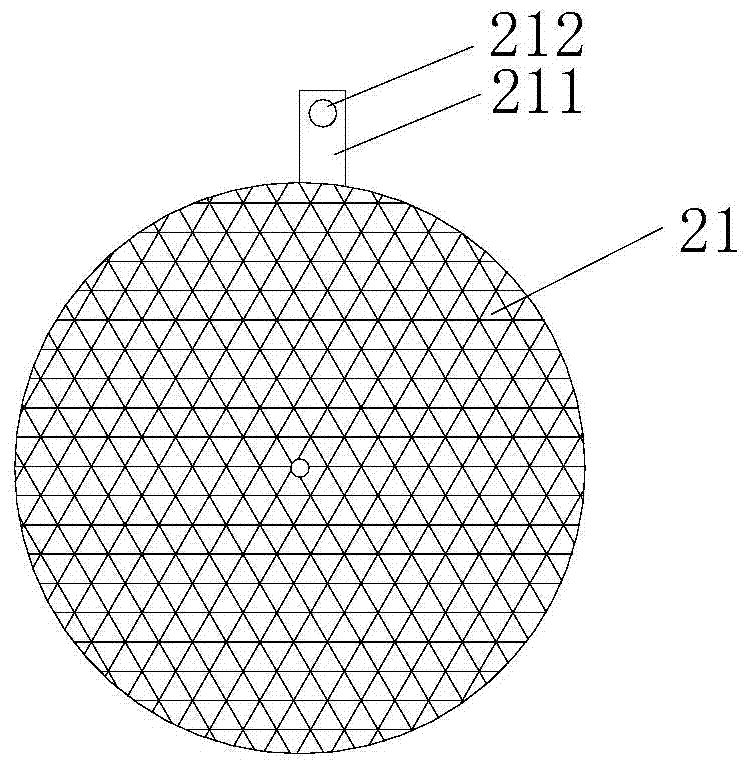

[0073] [Example 1]: Treatment of methyl orange wastewater

[0074] The titanium mesh loaded with iridium-tantalum oxide coating is used as a disc-shaped anode sheet 21, and the activated carbon fiber felt is used as a disc-shaped cathode sheet assembly 22, with an electrode area of 32 cm 2 , electrode spacing 10mm, simulated wastewater methyl orange concentration 500mg / L, supporting electrolyte 0.05mol / LNa 2 SO 4 , the volume of treated wastewater is 300ml. The reactor is filled with air to 0.25MPa, and the dissolved oxygen concentration is above 20mg / L. When using the enhanced electrochemical oxidation wastewater treatment method, a certain voltage is applied to the cathode and anode, and the current density of the control electrode is 25mA / cm2 , and a comparative experiment with the same flow rate of air at normal pressure was carried out. After 30min enhanced electrochemical oxidation treatment, the removal rate of methyl orange reached 99.7%, while the removal rate un...

Embodiment 2

[0075] [Example 2]: cumulative concentration of hydrogen peroxide

[0076] The titanium mesh loaded with iridium-tantalum oxide coating is used as a disc-shaped anode sheet 21, and the activated carbon fiber felt is used as a disc-shaped cathode sheet assembly 22, with an electrode area of 32 cm 2 , electrode spacing 10mm, prepare 300ml of Na with a concentration of 0.05mol / L 2 SO 4 solution, with H 2 SO 4 Adjust the pH to 3. The reactor is filled with air to 0.4MPa, and the dissolved oxygen concentration is above 30mg / L. The current density is 80mA / cm 2 , the cumulative concentration of hydrogen peroxide can reach up to 5.2mmol / L during electrolysis for 90 minutes, while it is only 0.4mmol / L under normal pressure.

Embodiment 3

[0077] [Example 3]: Treatment of emulsion wastewater

[0078] The titanium mesh loaded with iridium-tantalum oxide coating is used as a disc-shaped anode sheet 21, and the activated carbon fiber felt is used as a disc-shaped cathode sheet assembly 22, with an electrode area of 32 cm 2 , the electrode spacing is 10mm, the COD concentration of the emulsion wastewater is 11000mg / L, and the supporting electrolyte is 0.05mol / LNa 2 SO 4 , the treatment volume is 300ml. The reactor is filled with air to 0.25MPa, and the dissolved oxygen concentration is above 20mg / L. When using the enhanced electrochemical oxidation wastewater treatment method, a certain voltage is applied to the cathode and anode, and the current density of the control electrode is 25mA / cm 2 , and a comparative experiment with the same flow rate of air at normal pressure was carried out. After 30 minutes of enhanced electrochemical oxidation treatment, the COD removal rate reached 66.3%, while the removal rate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com