Core-shell structure type copper-based catalyst as well as preparation method and application thereof

A copper-based catalyst, core-shell structure technology, applied in the preparation of hydroxyl compounds, chemical instruments and methods, preparation of organic compounds, etc. Amplified, stable performance, simple to prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

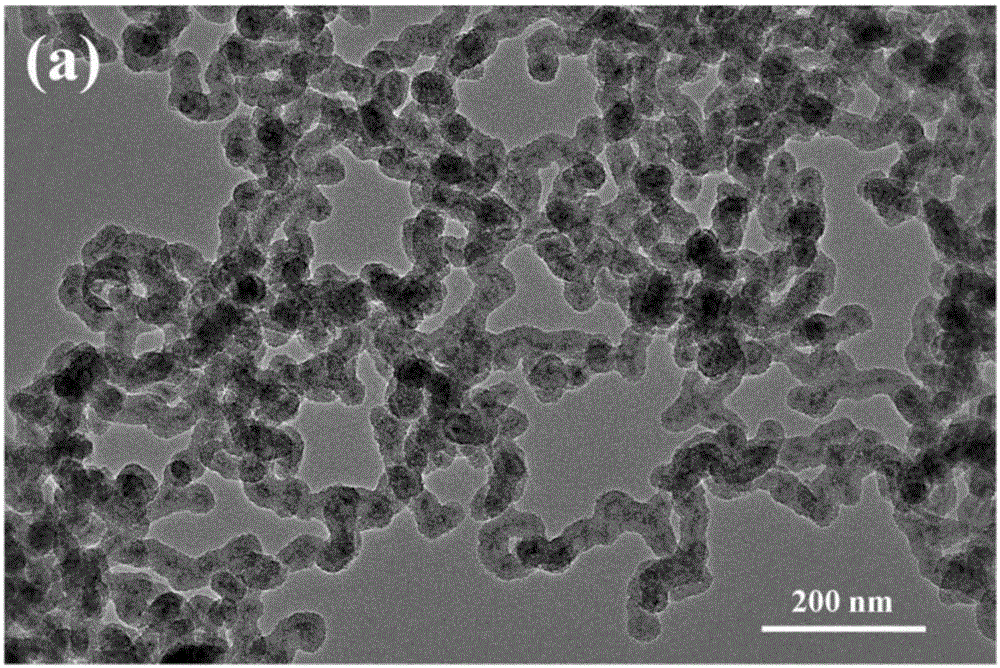

Image

Examples

Embodiment 1

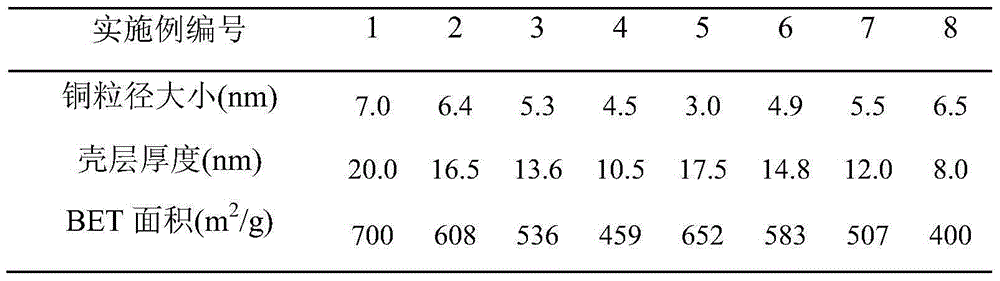

[0030] Preparation of the catalyst: Dissolve 0.182g of copper acetate in 1000mL of ethanol solvent, add 0.182g of polyvinylpyrrolidone as a stabilizer, stir until completely dissolved to obtain a precursor salt solution, and transfer the precursor salt solution to polytetrafluoroethylene CuO nanoparticles were prepared by reacting at 140 °C for 6 h in a lined reactor. Subsequently, the CuO nanoparticles were transferred to a mixed solution of ethanol (1000mL), deionized water (1000mL), and ammonia water (50mL) to react for 0.5h, and 3.644g of cetyltrimethylammonium bromide (CTAB ), continue to react for 1h; then follow TEOS: Cu(Ac) 2 =10:1 (molar ratio), slowly add tetraethyl orthosilicate (TEOS) to the solution, and continue the reaction for 12h. After the reaction, wash twice with deionized water and ethanol respectively, and dry the obtained precipitate at 60°C overnight, and bake the dried sample at 450°C for 8 hours, so as to prepare the core-shell structure material CuO...

Embodiment 2

[0033] Preparation of the catalyst: Dissolve 0.364g of copper acetate in 1000mL of ethanol solvent, add 1.820g of polyvinylpyrrolidone as a stabilizer, stir until completely dissolved, obtain a precursor salt solution, transfer the precursor salt solution to polytetrafluoroethylene CuO nanoparticles were prepared by reacting at 150 °C for 5 h in a lined reactor. Subsequently, the CuO nanoparticles were transferred to a mixed solution of ethanol (1000mL), deionized water (1000mL), and ammonia water (100mL) to react for 0.5h, 5.831gCTAB was added thereto, and the reaction was continued for 1h; then according to TEOS: Cu(Ac ) 2 =3:1 (molar ratio), slowly add TEOS to the solution, and continue to react for 24h. After the reaction, wash twice with deionized water and ethanol respectively, and dry the obtained precipitate at 70°C overnight, and bake the dried sample at 500°C for 6h to prepare CuO@m-SiO 2 .

[0034] Take 1.00 g of the above sample and put it in a fixed-bed reactor...

Embodiment 3

[0036] Preparation of the catalyst: Dissolve 0.546g of copper acetate in 1000mL of ethanol solvent, add 8.190g of polyvinylpyrrolidone as a stabilizer, stir until completely dissolved to obtain a precursor salt solution, and transfer the precursor salt solution to polytetrafluoroethylene CuO nanoparticles were prepared by reacting at 160 °C for 4 h in a lined reactor. Subsequently, the CuO nanoparticles were transferred to a mixed solution of ethanol (1000mL), deionized water (1000mL), and ammonia water (150mL) to react for 0.5h, 6.560gCTAB was added thereto, and the reaction was continued for 1h; then according to TEOS: Cu(Ac ) 2 =6:1 (molar ratio), slowly add TEOS to the solution, and continue to react for 36h. After the reaction, wash twice with deionized water and ethanol each, and dry the obtained precipitate at 80°C overnight, and bake the dried sample at 550°C for 5h to prepare CuO@m-SiO 2 .

[0037] Take 1.00 g of the above sample and put it in a fixed-bed reactor, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com