Impurity removal method for positive active material of lithium-ferrous disulfide battery

A positive electrode active material, ferrous disulfide technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery electrical performance impact, not in line with economic principles, acid is not easy to remove, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The positive electrode active material of the lithium-iron disulfide battery is subjected to impurity removal treatment, and the steps are as follows:

[0027] Commercially available ferrous disulfide powder is used as the positive electrode active material of the lithium-ferrous disulfide battery; in order to simulate the influence of the ferrous disulfide powder being damp during use, the ferrous disulfide powder is placed at a humidity of 75% ± 5 %, placed in an environment with a temperature of 25°C±5°C for 5 days;

[0028] The mixed solvent (DOL:DME=75wt%:25wt%) of gained ferrous disulfide powder is carried out Soxhlet extraction with ethylene glycol dimethyl ether and 1,3-dioxolane, and the temperature of Soxhlet extraction method is 80 ℃;

[0029] Then vacuum-dry the ferrous disulfide powder: bake the ferrous disulfide powder under the vacuum condition of 100° C. until the moisture content is below 0.1 wt%.

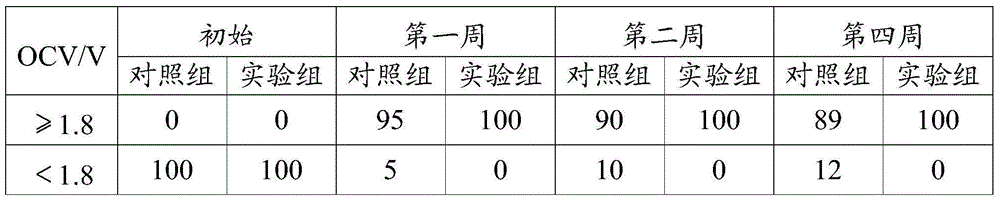

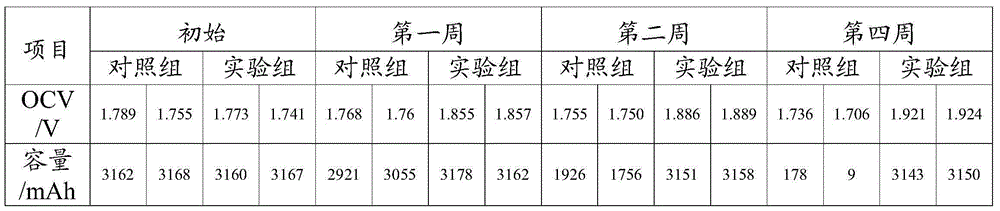

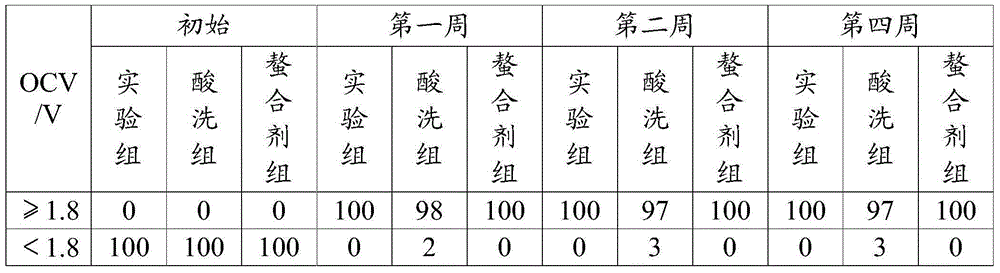

[0030] The ferrous disulfide powder after the impuri...

Embodiment 2

[0032] The positive electrode active material of the lithium-iron disulfide battery is subjected to impurity removal treatment, the method and steps are basically the same as those in Example 1, the difference is that:

[0033] 1. In the mixed solvent of ethylene glycol dimethyl ether and 1,3-dioxolane, the weight percentage of ethylene glycol dimethyl ether is 45%, and the weight percentage of 1,3-dioxolane is 55%;

[0034] 2. The temperature of the Soxhlet extraction method is 70°C;

[0035] 3. The temperature for vacuum drying the ferrous disulfide powder is 70°C.

Embodiment 3

[0037] The positive electrode active material of the lithium-iron disulfide battery is subjected to impurity removal treatment, the method and steps are basically the same as those in Example 1, the difference is that:

[0038] 1. In the mixed solvent of ethylene glycol dimethyl ether and 1,3-dioxolane, the weight percentage of ethylene glycol dimethyl ether is 35%, and the weight percentage of 1,3-dioxolane is 65%;

[0039] 2. The temperature of the Soxhlet extraction method is 90°C;

[0040] 3. The temperature for vacuum drying the ferrous disulfide powder is 150°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com