Welding process of cutting pick head and cutting pick base of coal cutter

A technology of welding process and pick seat, which is applied in the field of picks, can solve the problems that the efficiency of mining machinery cannot be fully utilized, the hard alloy pick head falls off, and the service life cannot be met, so as to facilitate large-scale mechanized production, Improved production efficiency and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

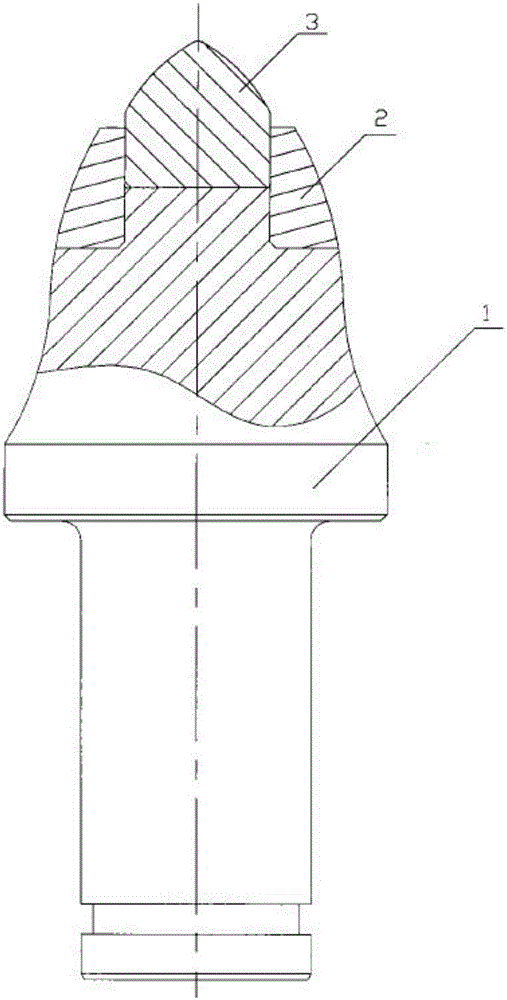

[0019] see figure 1 : A welding process of a shearer pick head and a pick seat, comprising a pick handle 1, a pick seat 2 and a pick head 3, the pick seat 2 is connected to one end of the pick handle 1, and the pick The tooth head 3 is fixed in the pick holder 2, and the connection mode between the said pick head 3 and the pick holder 2 is copper brazing, and the welding process is as follows:

[0020] 1. Open the valve of the welding torch and ignite the welding torch, at this time black smoke will come out from the welding torch;

[0021] 2. Turn the oxygen regulating valve to make the flame on the tip of the welding torch evenly distributed, so that the temperature of the flame on the tip reaches 2900-3100°C;

[0022] 3. Use a welding torch to burn the contact part between the pick head and the pick holder and keep the distance between the welding tip and the welding part between 3-5cm. Make the welding torch move quickly and evenly, so that the contact part is heated even...

Embodiment 2

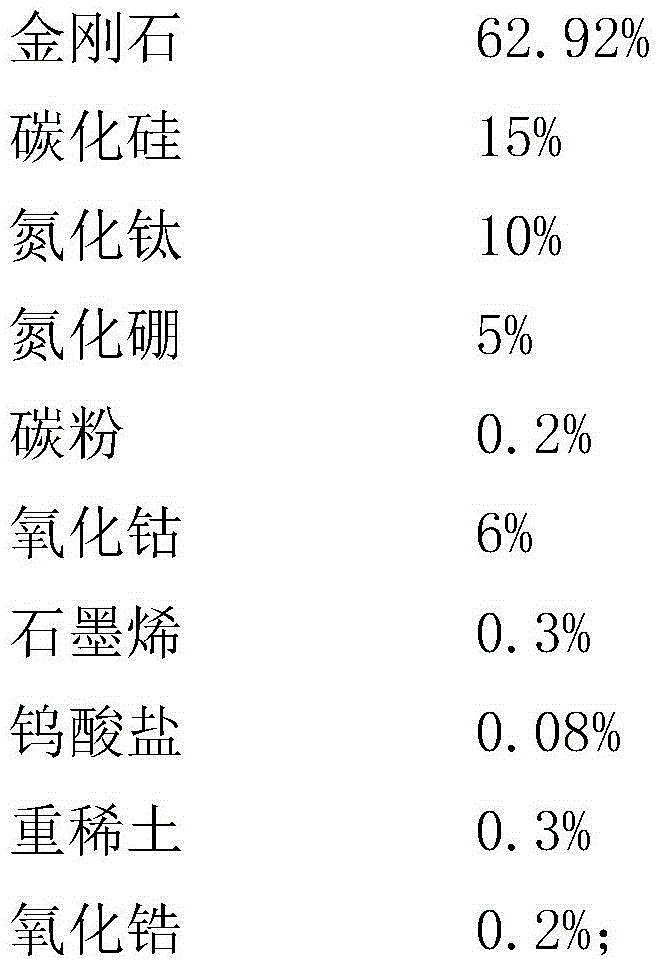

[0026] see figure 1 : A welding process of a shearer pick head and a pick seat, comprising a pick handle 1, a pick seat 2 and a pick head 3, the pick seat 2 is connected to one end of the pick handle 1, and the pick The tooth head 3 is fixed in the pick seat 2, and the pick head 3 includes a cemented carbide substrate and a diamond alloy layer coated on the end of the cemented carbide substrate, and the diamond alloy layer is surfacing welded on by diamond alloy powder. On the surface of the cemented carbide substrate end, a diamond alloy layer is formed, and the diamond alloy powder is made of the following components in mass percentage:

[0027]

[0028]

[0029] When the above diamond alloy powder is welded, it needs to generate 1500-2000°C within 0.5 seconds, and the diamond alloy powder is welded to the pick head to increase wear resistance, so that it can be matched with the alloy to achieve year-on-year wear. Because the instantaneous high temperature will not da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com