Magnetic graphene-loaded palladium nano-composite catalyst and preparation method thereof

A composite catalyst, magnetic graphene technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as restricting practical applications, difficult separation and recovery, poor filtration and centrifugation effects, etc. Achieving good magnetic effect, easy separation and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of graphene oxide:

[0028] Cool 200mL of concentrated sulfuric acid to 0°C, add 10g of graphite powder and 6g of sodium nitrate, slowly add 40g of potassium permanganate under stirring, keep the system temperature not exceeding 20°C, stir well and put it in a water bath at 35°C After reacting for 120 minutes, add 1000 mL of deionized water to keep the temperature of the system not exceeding 98°C, and continue stirring for 30 minutes; add 600 mL of deionized water and 50 mL of 30% H 2 o 2 , filtered, with 1mol·L -1 Wash the filter cake with HCl until SO4 cannot be detected in the filtrate 2- , and then washed with deionized water to become neutral, centrifuged, and vacuum-dried to obtain black graphene oxide powder.

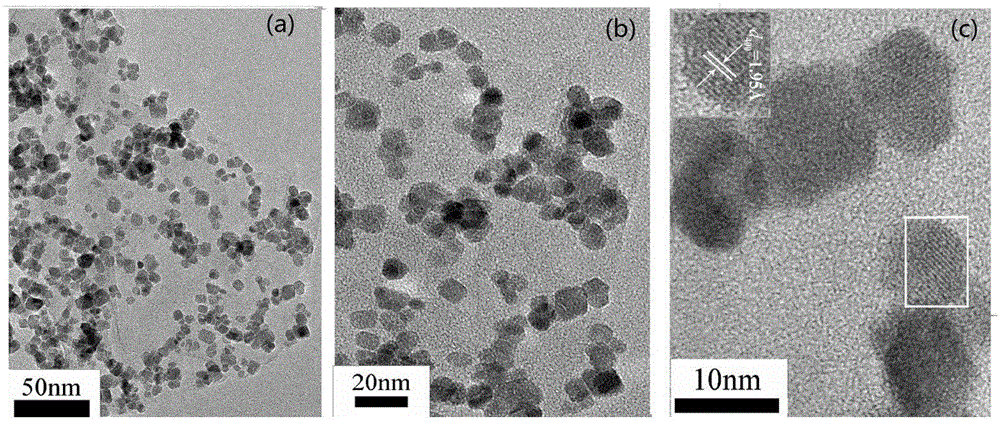

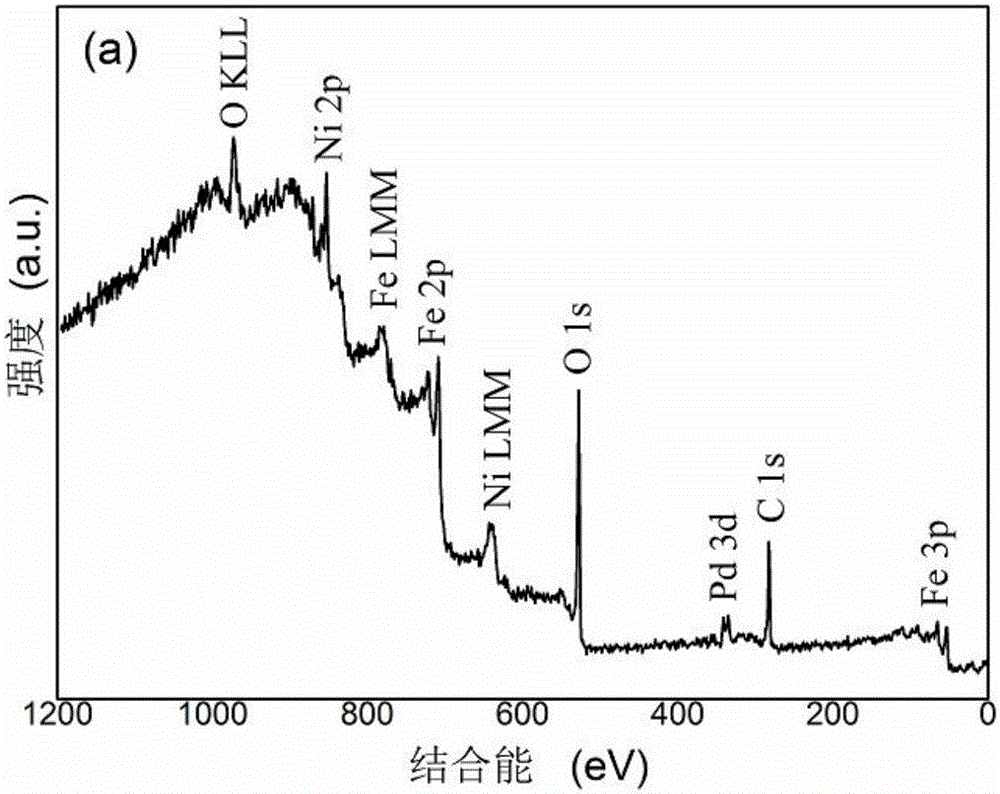

[0029] Preparation of nickel ferrite graphene supported palladium nanocomposite catalyst:

[0030] Add 0.1g of graphene oxide to 100mL of deionized water, ultrasonically disperse for 2h, and add to a mixture of 0.5g of nickel chl...

Embodiment 2

[0035] Add 0.2g of graphene oxide to 200mL of deionized water, ultrasonically disperse for 2h, and add to a solution consisting of 1.2g of nickel bromide trihydrate, 3.6g of iron nitrate nonahydrate and 200mL of polyethylene glycol / deionized water , the mixed solution was stirred for 2 h, and then sodium hydroxide solution was slowly added dropwise to adjust the pH value of the solution reaction system to 10, the mixed solution was transferred to a hydrothermal reactor, and then heated to 150° C. and maintained for 10 h. The reaction was naturally cooled to room temperature, the reaction product was filtered, rinsed with deionized water and ethanol to obtain nickel ferrite graphene oxide (NiFe 2 o 4 GO) complex. Add this complex to 200mL of deionized water, ultrasonically disperse for 2h, add 0.3g of palladium chloride, then add 0.05g of sodium borohydride, transfer the mixed solution to a hydrothermal reaction kettle, then heat to 120°C and keep After 4 hours, the reaction ...

Embodiment 3

[0037] Add 0.3g graphene oxide to 400mL deionized water, ultrasonically disperse for 2h, add 2.1g nickel sulfate hexahydrate, 7.0g ferric sulfate and 200mL polyethylene glycol / deionized water solution, mix the solution After stirring for 2 h, ammonia water was slowly added dropwise to adjust the pH value of the reaction system to 11, and the mixed solution was transferred to a hydrothermal reactor, and then heated to 180° C. and maintained for 10 h. The reaction was naturally cooled to room temperature, the reaction product was filtered, rinsed with deionized water and ethanol to obtain nickel ferrite graphene oxide (NiFe 2 o 4 GO) complex. Add this complex to 200mL of deionized water, ultrasonically disperse for 2 hours, add 0.4g of bistriphenylphosphine palladium dichloride, then add 0.1g of sodium borohydride, transfer the mixed solution to a hydrothermal reaction kettle, and then Heating to 150° C. and maintaining for 4 hours, cooling naturally to room temperature after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com