Metal product surface protection method

A technology for metal surfaces and metal products, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of insufficient density of protective film, uneven thickness, affecting appearance, etc., and achieve long service life and durability Good abrasiveness, high uniformity and thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

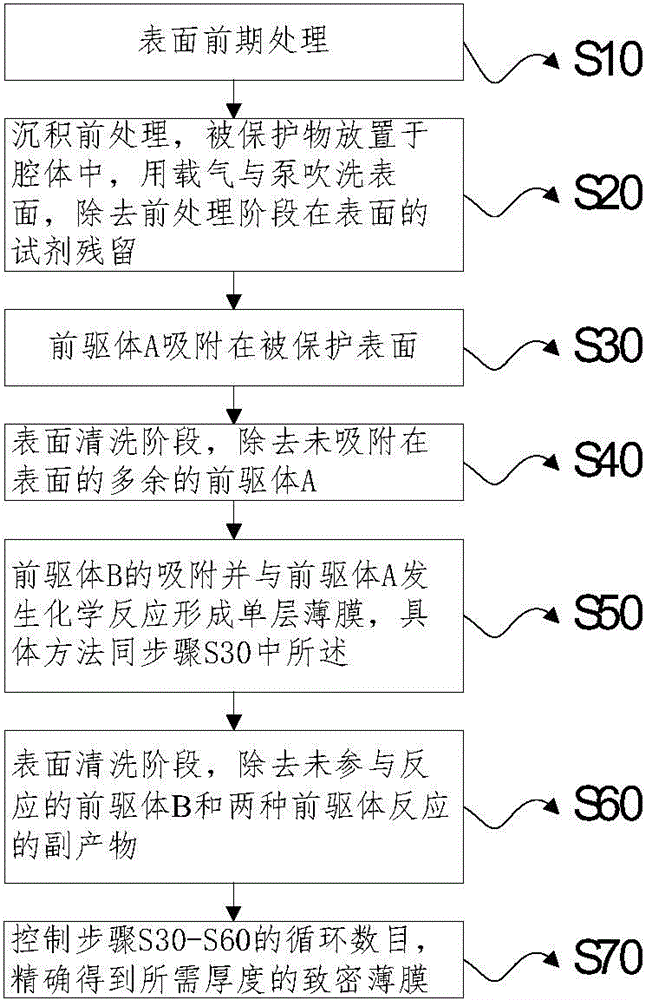

Method used

Image

Examples

Embodiment 1

[0069] Present embodiment is about 100cm to a piece of surface area 2 , and the surface of copper handicrafts with patina spots formed in the natural environment is subjected to atomic layer deposition, and coated with a layer of 5nm thick Al 2 o 3 film as an example, in which trimethylaluminum TMA and water H 2 O is the precursor, its The main reaction equation is:

[0070] (A)AlOH * +Al(CH 3 ) 3 →AlOAl(CH 3 ) 2 * +CH 4

[0071] (B)AlCH 3 * +H 2 O→AlOH * +CH 4

[0072] After the pre-treatment of the surface, place it in the reaction chamber of the atomic layer deposition equipment, the temperature of the chamber is 90°C, the vacuum pumping rate is adjusted to 100Pa / s by adjusting the flow rate of the vacuum pump, and the carrier gas flow rate is selected to be 500sccm to remove Part of the reagent used to clean the surface remains on it for about 1 hour, and the deposition reaction starts. After the pressure in the chamber is evacuated to 2O pulse for 10s, ...

Embodiment 2

[0074] Present embodiment is about 6cm to a piece of surface area 2 Atomic layer deposition was performed on the surface of silver coins, and a layer of 5nm thick TiO was coated 2 Thin film as an example, choose Ti[OCH(CH 3 )] 4 with H 2 O is the precursor, its The main reaction equation is:

[0075] Ti[OCH(CH 3 )] 4 +2H 2 O→TiO 2 +4(CH 3 ) 2 CHOH

[0076] After the pre-treatment of the surface, place it in the reaction chamber of the atomic layer deposition equipment, the temperature of the chamber is 90°C, and use the maximum vacuum rate and 100 sccm of carrier gas to remove the residue of some reagents used to clean the surface on it. After about 0.5 hour, the deposition reaction started. After the pressure in the cavity is reduced to 3 )] 4 Pulse for 5s, wait for 30s, turn on the vacuum pump and remove the precursor Ti[OCH(CH 3 )] 4 About 30s, turn off the pump and feed the precursor H 2 O pulse for 5s, wait for 30s, turn on the vacuum pump and remove the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com