Flexible fire-proof and explosion-proof blanket for cable intermediate joint

A cable intermediate joint and flexible technology, which is applied in cable joints, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of complex intermediate joint process, prolong emergency repair operation time, threaten life and safety, etc., to avoid burning. Spread, suppress the spread of burning, effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

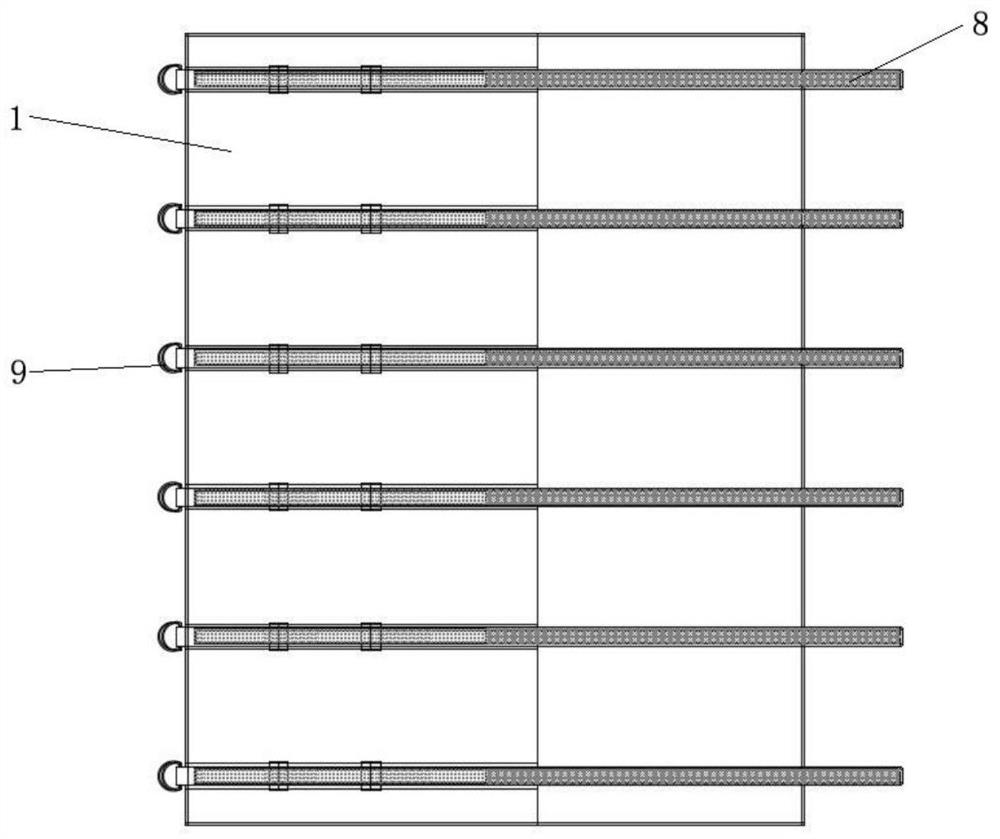

[0031] A flexible fireproof and explosion-proof blanket for intermediate joints of cables, comprising a fireproof and heat-insulating outer skin 1, a fire-proof and heat-insulating inner skin 2, and a fireproof cotton layer 3 interposed between the fireproof and heat-insulating inner and outer skins, and expandable graphite Granular layer 4, graphite-based flexible blanket 5, explosion-proof fiber layer 6 and waterproof fiber layer 7, the edges of the fireproof and heat-insulating outer skin 1 and the fire-proof and heat-insulating inner skin 2 are sewn together, and the fire-proof and heat-insulating outer skin 1 is sewn side by side with multiple bundles Band 8, the fire and explosion-proof blanket is wrapped around the middle joint of the cable through the strap 8.

[0032] The strap 8 is provided with Velcro. The Velcro includes a rough surface and a hook surface. The head end of the strap 8 is provided with a sun-shaped buckle. The end passes through the Japanese buckle a...

Embodiment 2

[0057] A flexible fireproof and explosion-proof blanket for intermediate joints of cables, comprising a fireproof and heat-insulating outer skin 1, a fire-proof and heat-insulating inner skin 2, and a fireproof cotton layer 3 interposed between the fireproof and heat-insulating inner and outer skins, and expandable graphite Granular layer 4, graphite-based flexible blanket 5, explosion-proof fiber layer 6 and waterproof fiber layer 7, the edges of the fireproof and heat-insulating outer skin 1 and the fire-proof and heat-insulating inner skin 2 are sewn together, and the fire-proof and heat-insulating outer skin 1 is sewn side by side with multiple bundles Band 8, the fire and explosion-proof blanket is wrapped around the middle joint of the cable through the strap 8.

[0058] The explosion-proof fiber layer 6 is made of Kevlar aramid fiber.

[0059] The waterproof fiber layer 7 is woven by polyester filaments and spinning needles, and its fibers are arranged in a three-dimens...

Embodiment 3

[0077] A flexible fireproof and explosion-proof blanket for intermediate joints of cables, comprising a fireproof and heat-insulating outer skin 1, a fire-proof and heat-insulating inner skin 2, and a fireproof cotton layer 3 interposed between the fireproof and heat-insulating inner and outer skins, and expandable graphite Granular layer 4, graphite-based flexible blanket 5, explosion-proof fiber layer 6 and waterproof fiber layer 7, the edges of the fireproof and heat-insulating outer skin 1 and the fire-proof and heat-insulating inner skin 2 are sewn together, and the fire-proof and heat-insulating outer skin 1 is sewn side by side with multiple bundles Band 8, the fire and explosion-proof blanket is wrapped around the middle joint of the cable through the strap 8.

[0078] The explosion-proof fiber layer 6 is made of Kevlar aramid fiber.

[0079] The waterproof fiber layer 7 is woven by polyester filaments and spinning needles, and its fibers are arranged in a three-dimens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com