Steel sheet for thick-walled high-strength line pipe having exceptional souring resistance, crush resistance properties, and low-temperature ductility, and line pipe

A technology of low temperature toughness and acid resistance, applied in the field of thick-walled and high-strength line pipe steel plate, which can solve the problems of crush resistance and low temperature toughness difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

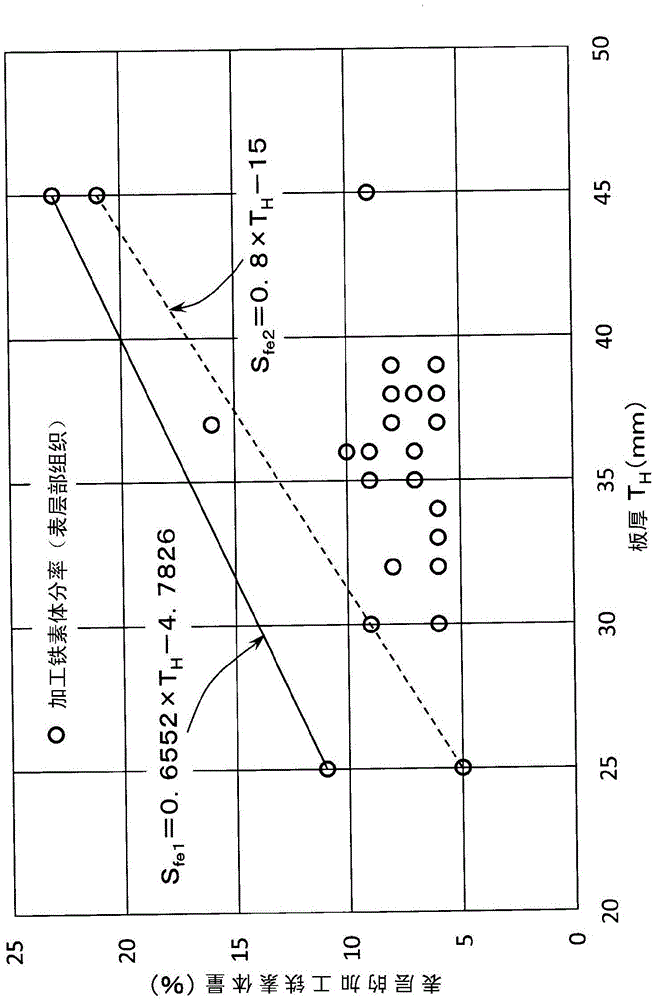

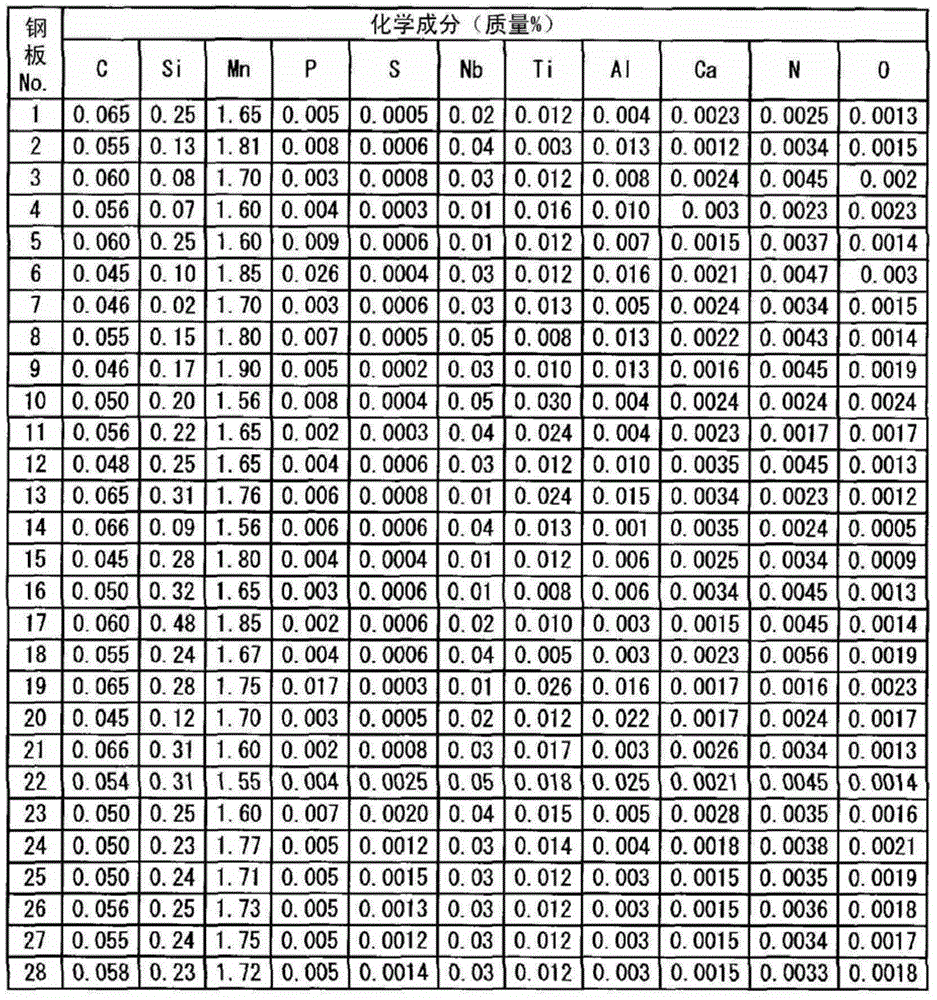

[0182] Next, examples of the present invention will be described, but the present invention is not limited to the conditions employed in the following examples.

[0183] Steels having the chemical components shown in Table 1-1, Table 1-2, Table 2-1, and Table 2-2 were melted and cast to produce billets. "Slab thickness" in Table 3-1 and Table 3-2 represents the thickness (mm) of the obtained slab. The steel slabs mentioned above are reheated respectively, and hot rolled in a recrystallized region exceeding 900°C. In addition, the "heating temperature" in Table 3-1 and Table 3-2 represents the above-mentioned reheating temperature, and the "transfer thickness" in Table 3-1 and Table 3-2 represents the temperature after hot rolling in the above-mentioned recrystallization region and which will be described later. Sheet thickness at 900°C before hot rolling in the non-recrystallized region of 900°C or lower. In addition, the "reduction ratio in the recrystallization domain" of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield stress | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com