Anode lead paste for power lead-acid storage battery and preparation method of anode lead paste

A lead-acid battery, negative lead paste technology, applied in lead-acid batteries, battery electrodes, circuits, etc., can solve problems such as short cycle life, and achieve the effects of improved cycle life, low temperature capacity, and high specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

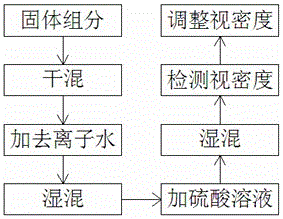

Image

Examples

specific Embodiment 1

[0022] Step 1, accurately refer to the following components: 0.6 copies of synthetic fibers, 20 sulfate, 0.5 parts of lignin, 1.5 sulfate tin, 1.5 sodium sulfate, 15 copies of polyiline;The synthetic fiber is one or more mixture of polyester fiber, proparior fiber and polyester fiber, which is 2 to 4mm in length of the synthetic fiber.

[0023] Step 2: Mix the components called step -one, then add it to the pipe machine together, accurately collect 1,000 lead powder with lead powder transportation pipes and add it to the pipe machine.The paste, stirred dry for 5 to 12 minutes to mix it evenly; the oxidation of the lead powder is 70%to 80%.

[0024] Step 3, add 90 copies of ionic water in two times: slowly add 40%to 70%of exfoliating water in 1 to 3 minutes, stir for 1 to 3 minutes, and then add the remaining amount of exfoliating ion ions for 1 to 3 minutes.Water, stir for 2 to 6 minutes; the conductivity of ionic water is less than 2us / cm.

[0025] Step 4. Slowly add a sulfuric a...

specific Embodiment 2

[0030] Step 2: Mix the components called step -one, then add it to the pipe machine together, accurately collect 1,000 lead powder with lead powder transportation pipes and add it to the pipe machine.The paste, stirred dry for 5 to 12 minutes to mix it evenly; the oxidation of the lead powder is 70%to 80%.

[0031] Step 3, add 110 copies of ion water in the quality of 110 copies: slowly add 40%to 70%of de -ion water in 1 to 3 minutes, stir for 1 to 3 minutes, and then add the remaining amount of exfoliating ion ions for 1 to 3 minutes.Water, stir for 2 to 6 minutes; the conductivity of ionic water is less than 2us / cm.

[0032] Step 4. Slowly add a sulfuric acid solution with a mass of 50%percentage. The mass of the sulfate solution is 80 copies, and the sulfuric acid solution is stirred for 15-25 minutes while adding the sulfate solution.

[0033] Step 5. Adjust the density of the lead cream from 4.4 ~ 4.6g / cm3.

[0034] The control temperature of the entire preparation process is...

specific Embodiment 3

[0038] Step 3, add 100 copies of ion water in the quality twice: slowly add 40%to 70%of de -ion water in 1 to 3 minutes, stir for 1 to 3 minutes, and then add the remaining amount of exfoliating ion ions for 1 to 3 minutes.Water, stir for 2 to 6 minutes; the conductivity of ionic water is less than 2us / cm.

[0039] Step 4. Slowly add a sulfuric acid solution with a mass of 50%percentage. The quality of the sulfuric acid solution is 100 copies, and the sulfuric acid solution is stirred for 15-25 minutes while adding the sulfate solution.

[0040] Step 5. Adjust the density of the lead cream from 4.4 ~ 4.6g / cm3.

[0041] The control temperature of the entire preparation process is not higher than 65 ° C.

[0042] project Example 1 Example 2 Example 3 2HR capacity (AH) 22.5 22.5 22.6 Charging Acceptance (A) 2.13 2.14 2.13 -15 ℃ Low temperature capacity (AH) 17.2 17.1 17.2 36A large current discharge (min) 29.8 29.7 29.9 Capacity preservatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| oxidation state | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com