Automatic grouting float collar and float shoe

An automatic grouting and floating hoop technology, used in the field of floating hoop and floating shoes, can solve the problems of reducing drilling time, product failure, poor drillability and sealing performance, reducing the amount of return and speed of return, and avoiding lost circulation. , the effect of reducing the impact pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

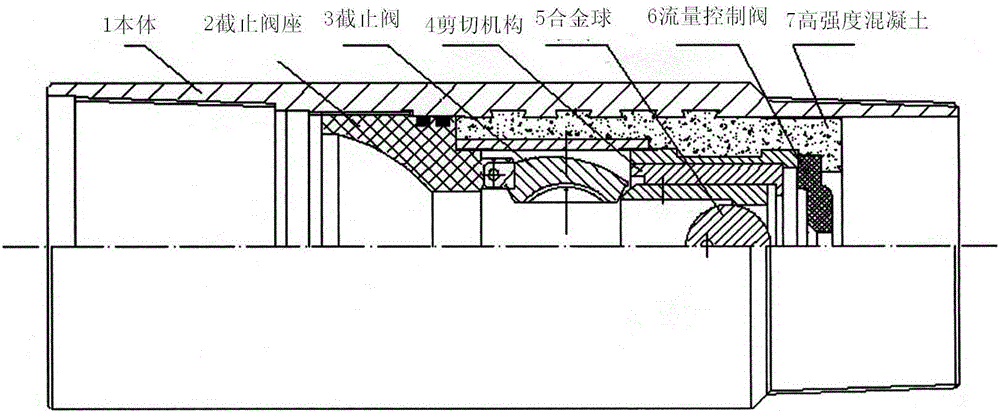

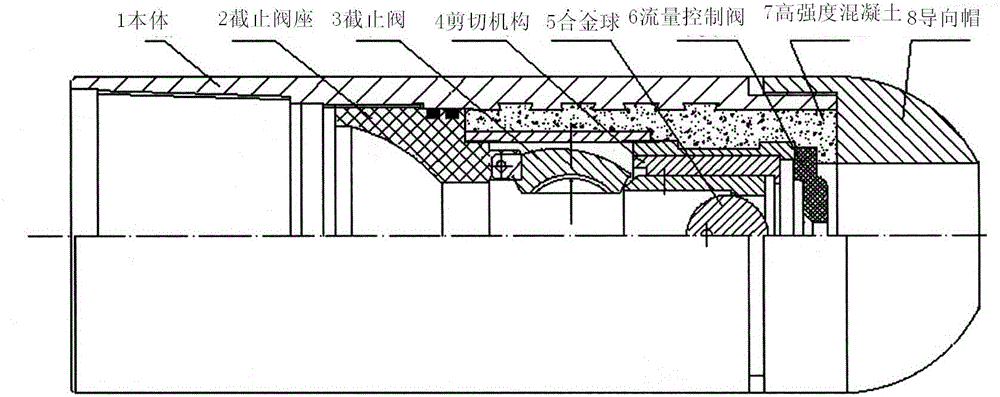

[0032] The upper and lower ends of the floating hoop body 1 or the upper end of the floating shoe body 1 are processed with casing circular threads or casing partial trapezoidal threads connected with the oil casing, and the lower end of the floating shoe body is equipped with a guide cap. The inner wall of the floating hoop and the floating shoe body 1 is connected with a stop valve seat 2 through a straight thread. The inner hole of the stop valve seat 2 is processed with an inclined surface as a sealing surface. A stop valve 3 is installed under the stop valve seat 2. The stop valve mainly It is composed of valve body, rotary shaft, torsion spring, etc. The sealing surface of the valve body is a spherical surface. The shearing mechanism 4 and the flow control valve 6 are fixed and sealed by high-strength concrete 7 on the floating hoop below the stop valve seat 2 and the inner wall of the floating shoe body 1. The shearing mechanism is divided into inner and outer sleeves, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com