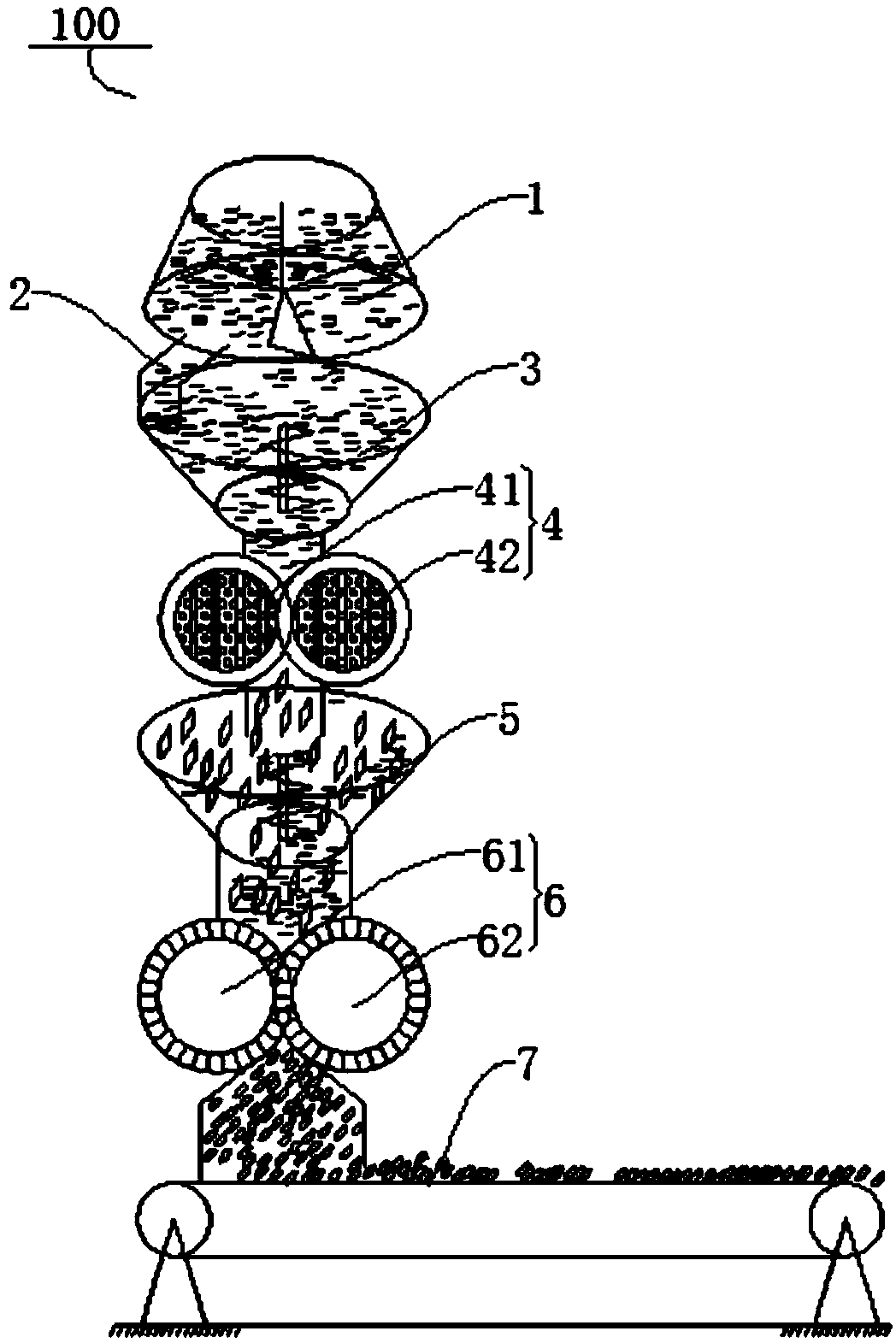

Pressing balling machine

A ball briquetting machine and ball briquetting technology, applied in the field of briquetting machines, can solve the problems of poor pellet strength, lower operating rate, difficult cleaning, etc., and achieve the effect of meeting strength requirements, improving production efficiency, and ensuring compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

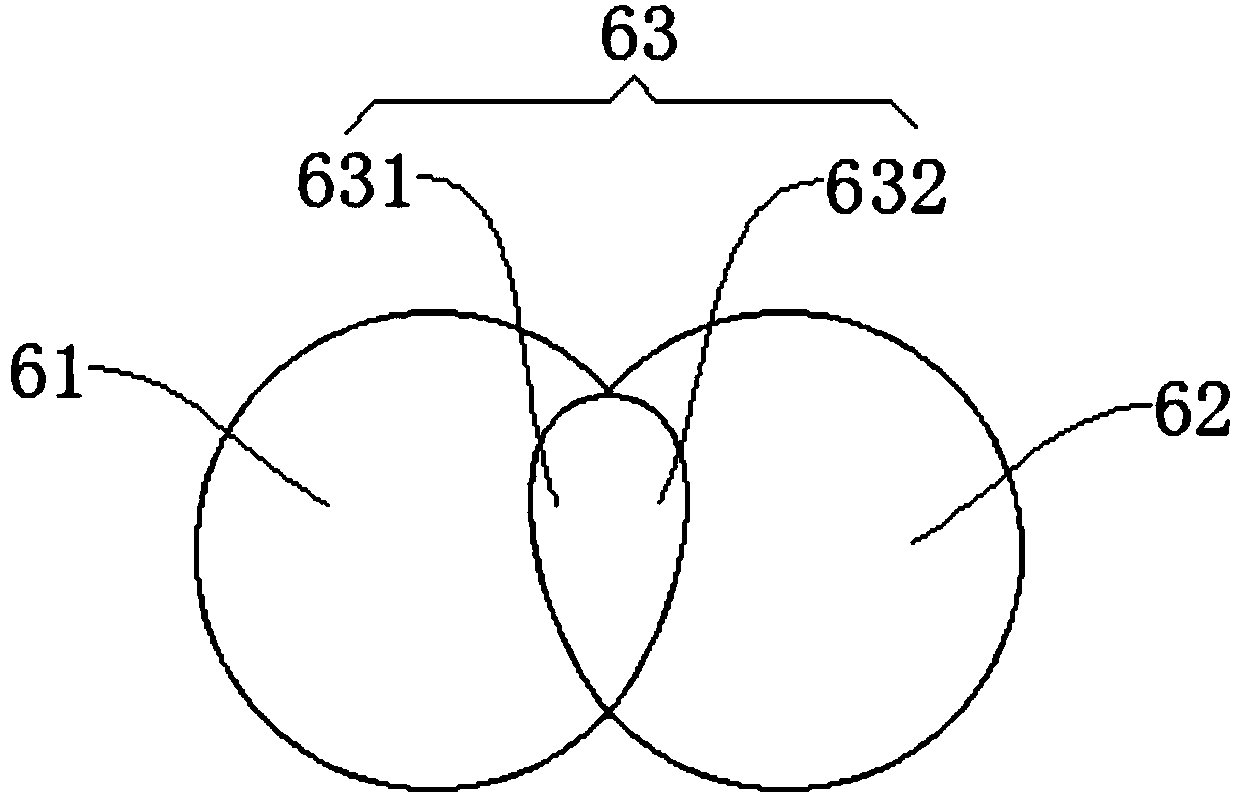

[0056] Use red mud as raw material, add a certain amount of reducing agent, limestone and binder, mix them evenly in the mixing system 1, and then carry out ball pressing operation, wherein the ratio of red mud: reducing agent: limestone: binder is 100 : 15.6: 6: 2, add a certain amount of water during the mixing process to ensure that the water content of the mixture is 17-18%, adjust the parameters of the first ball pressing system 4 and the second ball pressing system 6, and set the first ball pressing system 4 The distance between the first pressure roller 41 and the second pressure roller 42 is 0.5mm, the pressure between the first pressure roller 41 and the second pressure roller 42 is set to 8MPa, the frequency of the first conveying system 3 is 35Hz, the first The frequency 20Hz of pressure roller 41 and the second pressure roller 42, the distance between the third pressure roller 61 and the fourth pressure roller 62 in the second pressure ball system 6 is set to be 0.5...

Embodiment 2

[0058] Use red mud as raw material, add a certain amount of reducing agent, limestone and binder, mix them evenly in the mixing system 1, and then carry out ball pressing operation, wherein the ratio of red mud: reducing agent: limestone: binder is 100 : 15.6: 6: 2, add a certain amount of water during the mixing process to ensure that the water content of the mixture is 17-18%, adjust the parameters of the first ball pressing system 4 and the second ball pressing system 6, and set the first ball pressing system 4 The distance between the first press roller 41 and the second press roller 42 is 3mm, the pressure between the first press roller 41 and the second press roller 42 is set to 8MPa, the frequency of the first conveying system 3 is 35Hz, the first press The frequency of the roller 41 and the second pressure roller 42 is 20Hz, and the distance between the third pressure roller 61 and the fourth pressure roller 62 is set to be 0.5mm in the second pressure ball system 6, an...

Embodiment 3

[0060]Use red mud as raw material, add a certain amount of reducing agent, limestone and binder, mix them evenly in the mixing system 1, and then carry out ball pressing operation, wherein the ratio of red mud: reducing agent: limestone: binder is 100 : 15.6: 6: 2, add a certain amount of water during the mixing process to ensure that the water content of the mixture is 17-18%, adjust the parameters of the first ball pressing system 4 and the second ball pressing system 6, and set the first ball pressing system 4 The distance between the first pressure roller 41 and the second pressure roller 42 is 1.5mm, the pressure between the first pressure roller 41 and the second pressure roller 42 is set to 9MPa, the frequency of the first conveying system 3 is 35Hz, the first The frequency of the pressure roller 41 and the second pressure roller 42 is 20Hz, and the distance between the third pressure roller 61 and the fourth pressure roller 62 in the second pressure ball system 6 is set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com