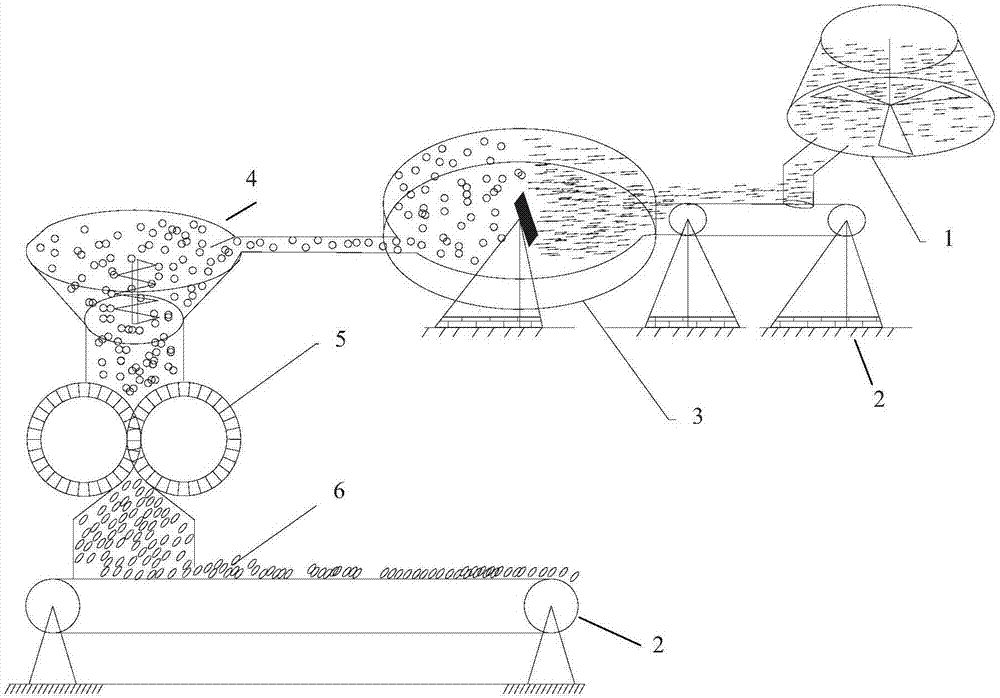

Pelletizing system and pelletizing method

A ball-forming and ball-making technology, which is applied to the ball-forming system and the field of ball-forming, can solve the problems of reduced operation rate, large amount of returned material, and poor pellet strength, so as to improve the strength and ball-forming rate, and meet the requirements of strength. , The effect of improving the strength of the pellet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

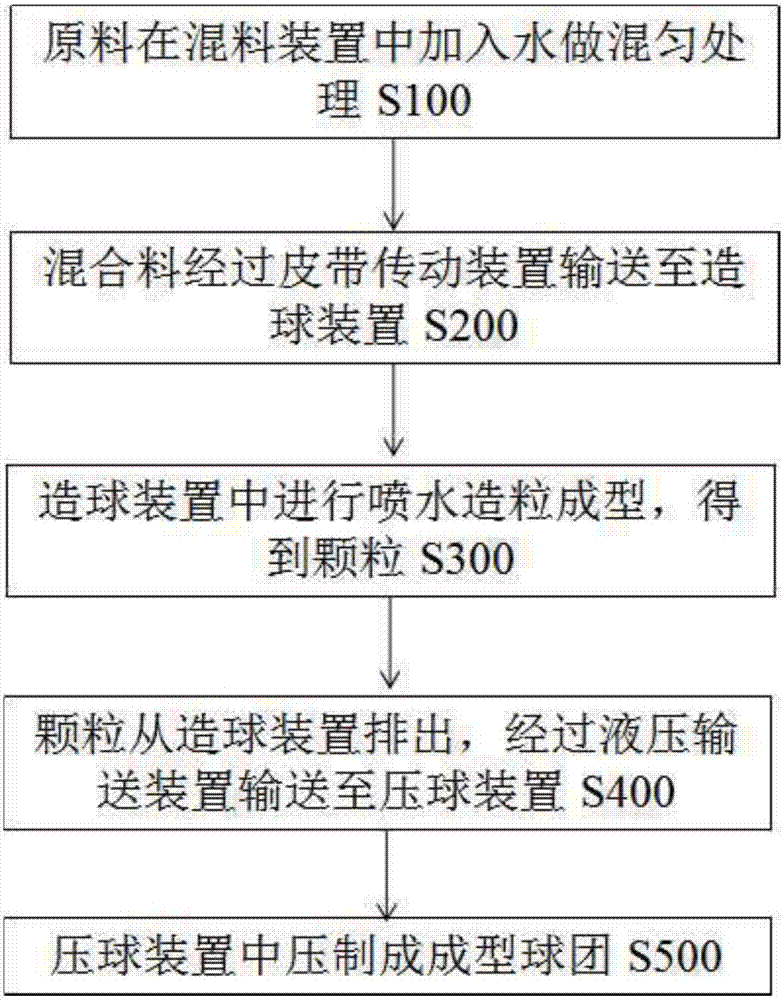

[0062] Red mud is used as raw material, and a certain amount of reducing agent, limestone and binder are mixed in the mixing device. The ratio of red mud: reducing agent: limestone: binder is 100:17:8 : 3, add 8% water to the raw material in the mixing device, and the mixed material enters the disc pelletizer for water spray granulation, and the amount of water added is 10% of the mass percentage of the mixed material to ensure that the granular The water content of the material is 17-19%, and the size of the fine particles obtained by the disc pelletizer is 4-5mm. Adjust the parameters of the briquetting machine. The size of the ball socket is: length 32-36mm, width 24-30mm, depth 8-12mm, the distance between the rollers of the briquetting machine is set to 0.5mm, and the pressure on the rollers is set to 10MPa. The frequency of the pre-pressing screw is 40Hz, and the frequency of the main machine is 25Hz. Under the conditions of the ball pressing parameters, the final red mu...

Embodiment 2

[0066] Red mud is used as raw material, and a certain amount of reducing agent, limestone and binder are mixed in the mixing device. The ratio of red mud: reducing agent: limestone: binder is 100:17:8 : 3, the raw material is added 10% water in the mixing device, and the mixed material enters the disc pelletizer to carry out water spray granulation molding, and the amount of water added is 6% of the mass percentage of the mixed material to ensure that the granular The water content of the material is 17-19%, and the size of the fine particles obtained by the disc pelletizer is 4-5mm. Adjust the parameters of the ball-pressing machine in the ball-pressing system. The size of the ball socket is: length 32-36mm, width 24- 30mm, depth 8-12mm, the distance between the rollers of the briquetting machine is set to 2mm, the pressure on the rollers is set to 16MPa, the frequency of the pre-pressing screw is 50Hz, and the frequency of the main machine is 32Hz. Under the conditions of the...

Embodiment 3

[0068] Red mud is used as raw material, and a certain amount of reducing agent, limestone and binder are mixed in the mixing device. The ratio of red mud: reducing agent: limestone: binder is 100:17:8 : 3, the raw material is added 9% water in the mixing device, and the mixed material enters in the disc pelletizer and carries out water spray granulation molding, and the amount of adding water is to account for 7% of the mass percentage of the mixed material, to ensure granular The water content of the material is 17-19%, and the size of the fine particles obtained by the disc pelletizer is 4-5mm. Adjust the parameters of the ball press machine. The size of the ball socket is: length 32-36mm, width 24-30mm, depth 8 ~12mm, the distance between the rollers of the briquetting machine is set to 1mm, the pressure on the rollers is set to 13MPa, the frequency of the pre-pressing screw is 44Hz, and the frequency of the main engine is 28Hz. The ball rate is 98.2%. The length of the sha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com