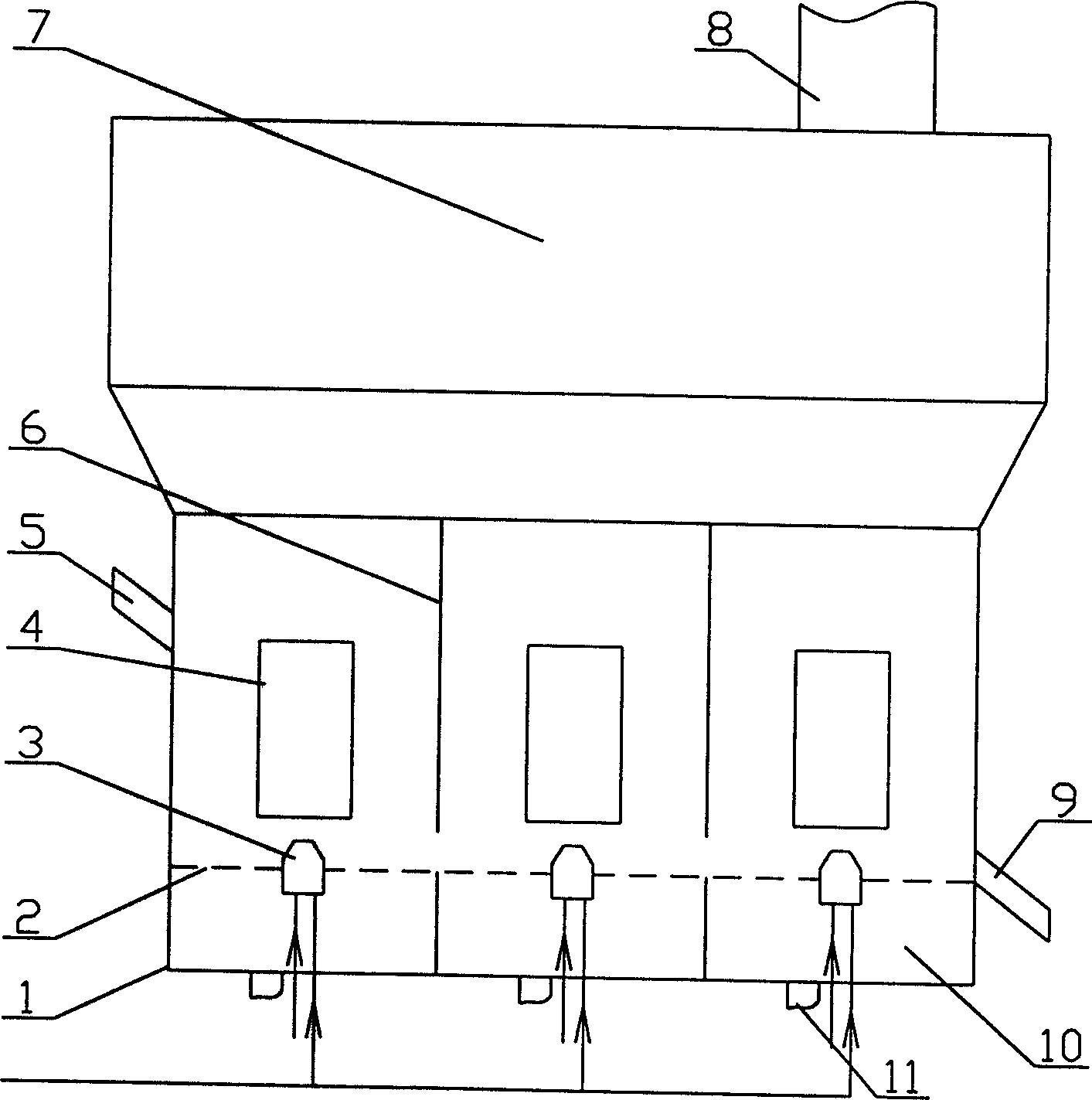

Jet drive fluidized bed pelletizing device with multiple jet drive units

A spouted fluidized bed and granulation technology, applied in the field of spouted fluidized bed granulators and granulation devices, can solve the problems of difficulty in continuity, clogging of nozzles, back-mixing of particle granulators, etc., and achieve the equipment structure. Simple, improved uniformity, guaranteed continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

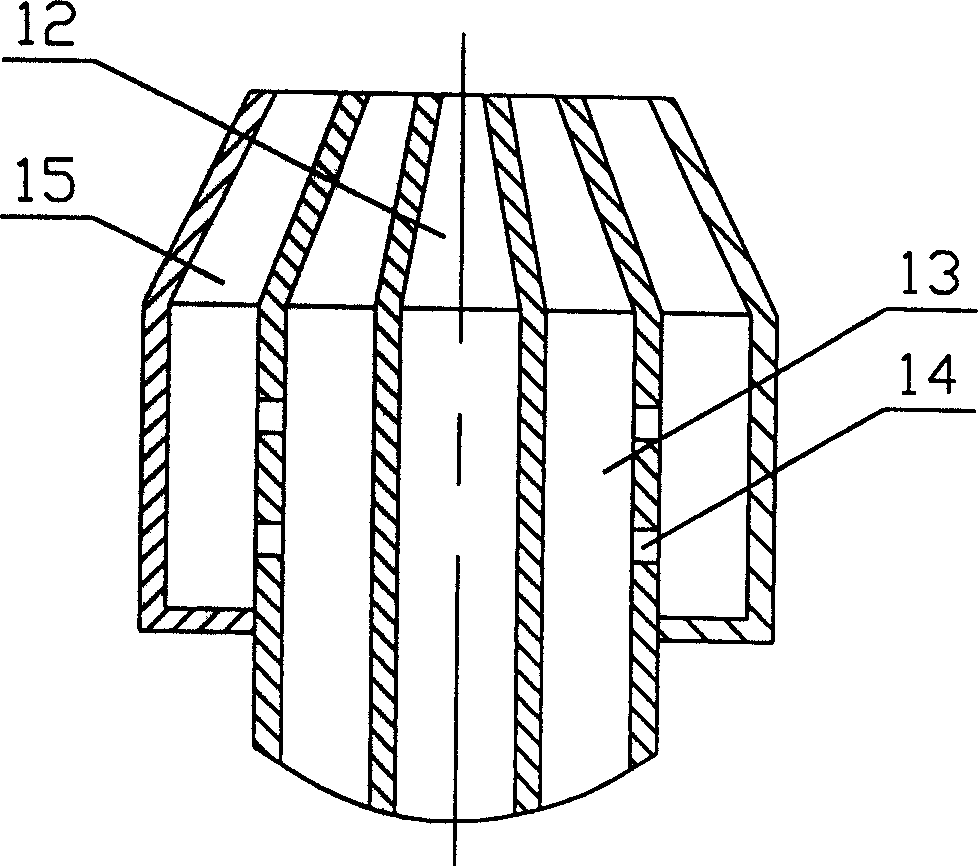

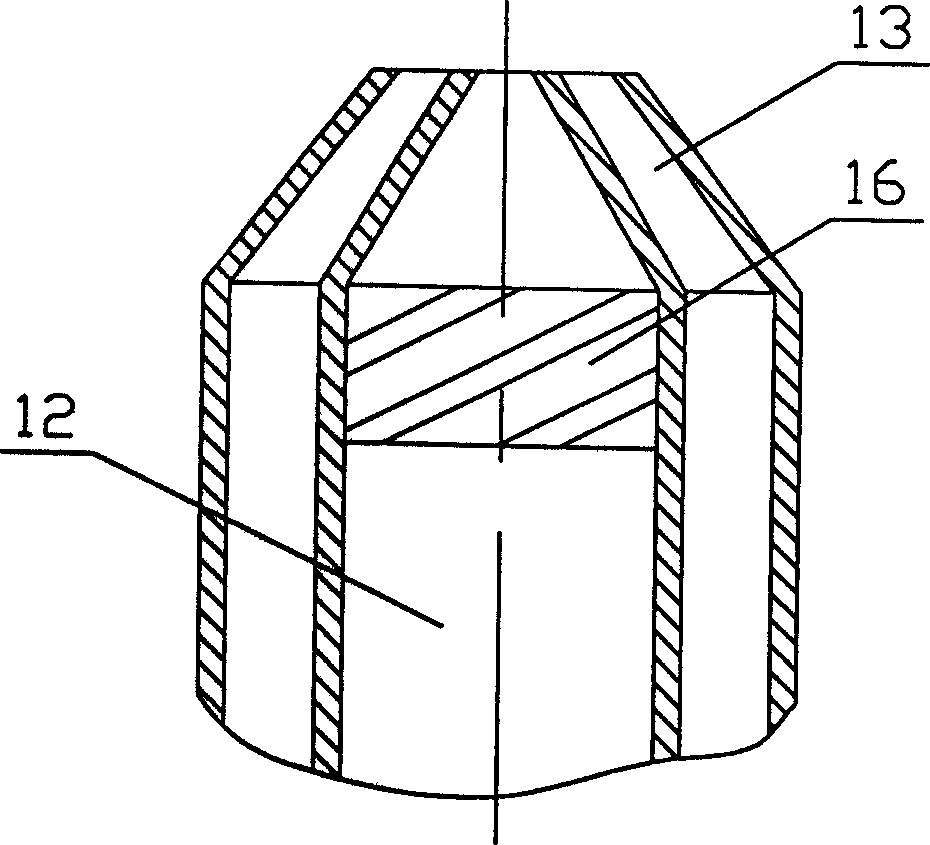

[0012] The invention is applied to the manufacture of spherical anhydrous calcium chloride, and realizes industrial operation. In this device, each spraying unit is equipped with a φ150×500mm guide tube, the area ratio of the annular area to the spraying area is 3:1, and the opening ratio is 1:3. The angle between the inclined hole and the horizontal in the annular area is 60°. The nozzle used is the self-cleaning two-fluid nozzle of the present invention. The granular calcium chloride produced by applying the present invention has a uniform particle size (3-4mm) and a return rate of less than 30%. The device has been running continuously for more than 72 hours. Check the nozzle, and there is no material hanging at the nozzle of the nozzle. The device has been in operation for nearly a year, and no spouted fluidized bed cannot operate normally due to nozzle blockage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com