Phosphate rock micropowder pellets and preparation method thereof

A technology for micropowder pellets and micropowder balls, applied in the field of phosphorus chemical industry, can solve the problems of difficulty in controlling the production process of pellets, lowering the grade of phosphate rock pellets, complicated molding process of phosphate rock powder, etc. Low, high-intensity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

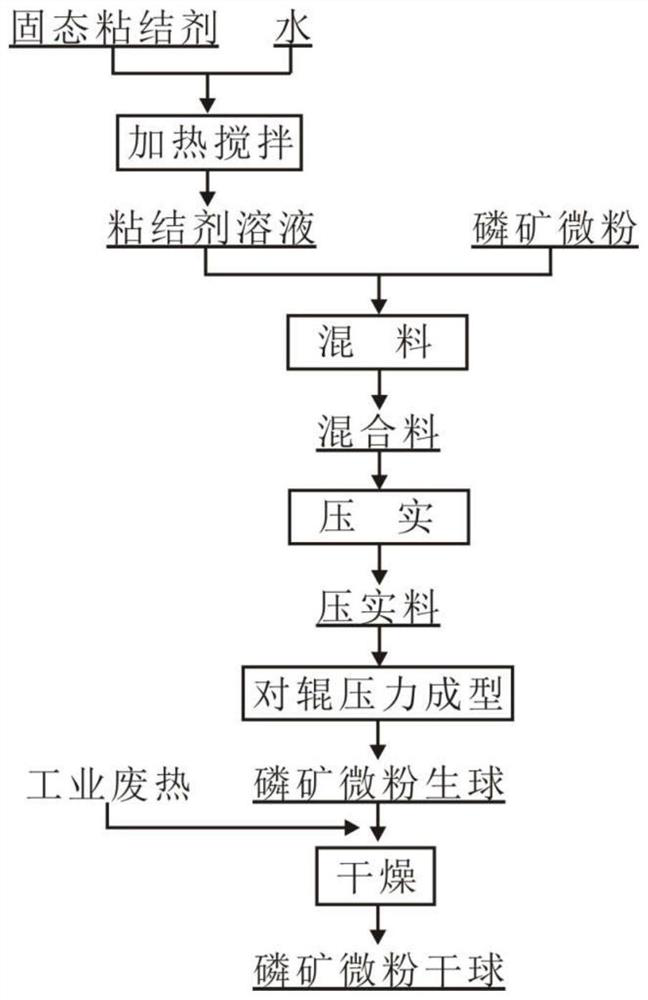

[0027] In order to solve the first technical problem of the present invention, the preparation method of the phosphate rock micropowder pellets comprises the following steps:

[0028] a. Mix the organic binder, water and phosphate rock powder evenly according to the mass ratio of 0.2~0.6:10~15:100 to obtain the mixed material; the mass ratio of the organic binder, water and phosphate rock powder is preferably 0.4~0.6 :12~15:100;

[0029] b. Pelletizing the mixed material at 6-12MPa to obtain green pellets of phosphate rock micropowder; the diameter of the phosphate rock micropowder green pellets is preferably 8-30mm;

[0030] c. drying the phosphate rock micropowder green pellets to obtain phosphate rock micropowder pellets.

[0031] The homogeneous mixing described in step a can be achieved by using conventional mixing methods such as stirring and shaking to mix the materials evenly, for example, using a mixer to mix the materials evenly.

[0032] The described briquetting ...

Embodiment 1

[0045] Phosphate rock micropowder 1000kg, required organic binder 2kg, water 100kg. That is: the mass ratio of phosphate rock micropowder, organic binder and water is 100:0.2:10.

[0046] Such as figure 1The preparation method of shown phosphate rock micropowder pellets comprises the following steps:

[0047] (1) 2kg polyvinyl alcohol dry powder and 100kg water were mixed uniformly at 80°C to obtain 102kg organic binder aqueous solution.

[0048] (2) Add the organic binder aqueous solution to 1000kg of phosphate rock micropowder, then mix and stir for 15min by a mixer to obtain 1102kg of mixed material;

[0049] (3) compacting the obtained mixed material on a compacting device to obtain a compacted material;

[0050] (4) The compacted material is pelletized with a pair of roller briquetting machines, and the pressure is set to 10Mpa to obtain phosphate rock micropowder raw pellets with a diameter of 8 to 30mm;

[0051] (5) Combustion of tail gas produced with yellow phosph...

Embodiment 2

[0053] Phosphate rock micropowder 1000kg, required organic binder 3kg, water 120kg. That is: the mass ratio of phosphate rock micropowder, organic binder and water is 100:0.3:12.

[0054] The preparation method of phosphate rock micropowder pellet comprises the following steps:

[0055] (1) Mix 3kg polyvinyl alcohol dry powder with 120kg water at 85°C to obtain 123kg organic binder aqueous solution;

[0056] (2) The aqueous solution of the organic binder is added to 1000kg of phosphate rock micropowder, then mixed uniformly and stirred by a mixer for 20min to obtain 1123kg of mixed material;

[0057] (3) compacting the mixed material on a compacting device to obtain a compacted material;

[0058] (4) Carry out pellet forming to the compacted material with a pair of roller briquetting machines, and the pressure is set to 8Mpa to obtain phosphate rock micropowder raw pellets with a diameter of 8 to 30mm;

[0059] (5) Combustion of tail gas produced with yellow phosphorus, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com