System and method for resource utilization of dust and sludge containing iron and zinc

A recycling and dust sludge technology, applied in the fields of metallurgy and energy, can solve the problems of poor applicability and stability of complex raw materials, high requirements for dry and wet pellet strength, high production and use costs, and achieve improved dry and wet strength and thermal stability performance, reduce pulverization rate, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

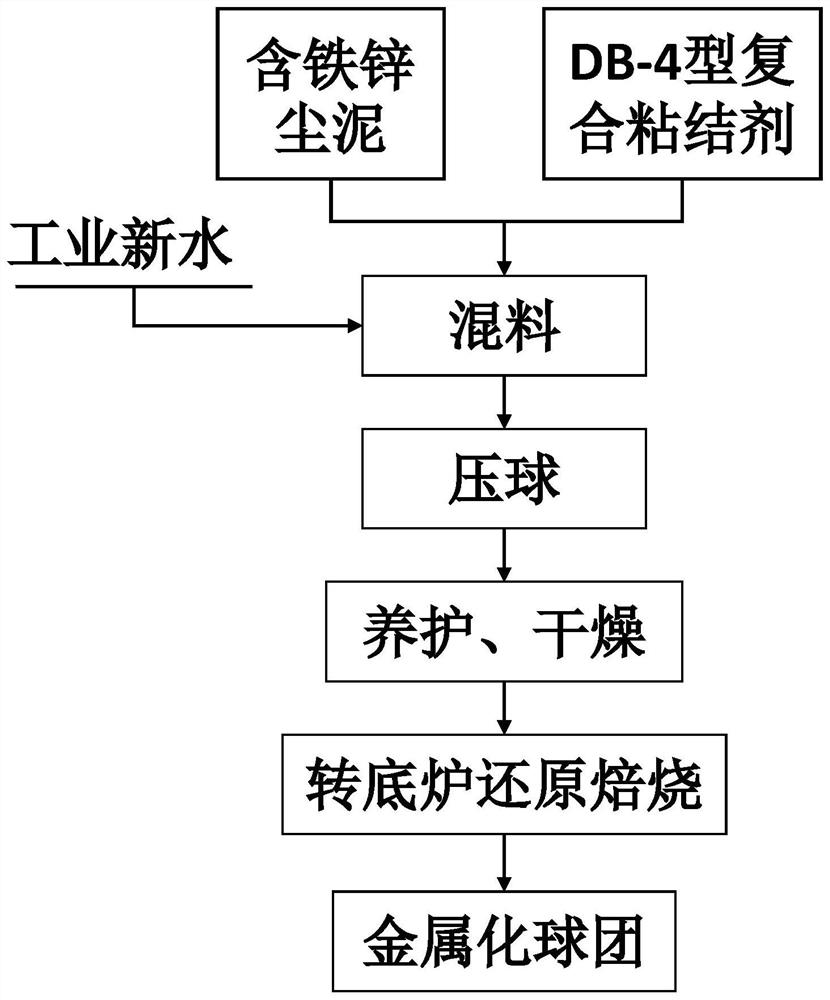

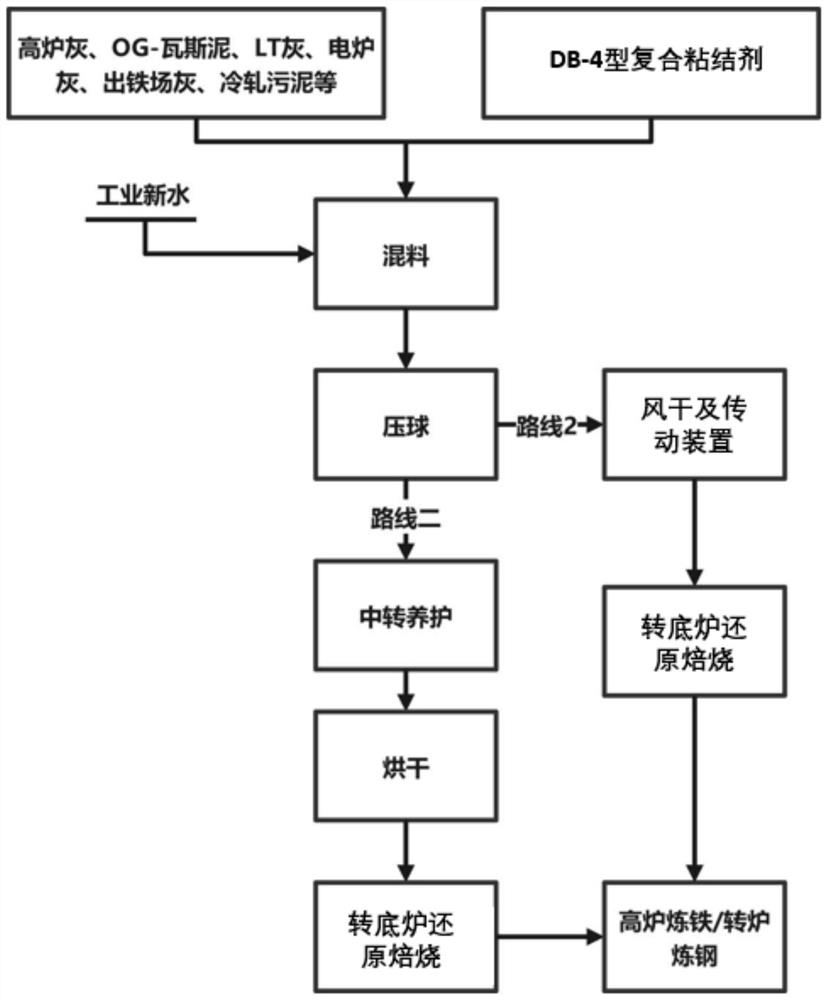

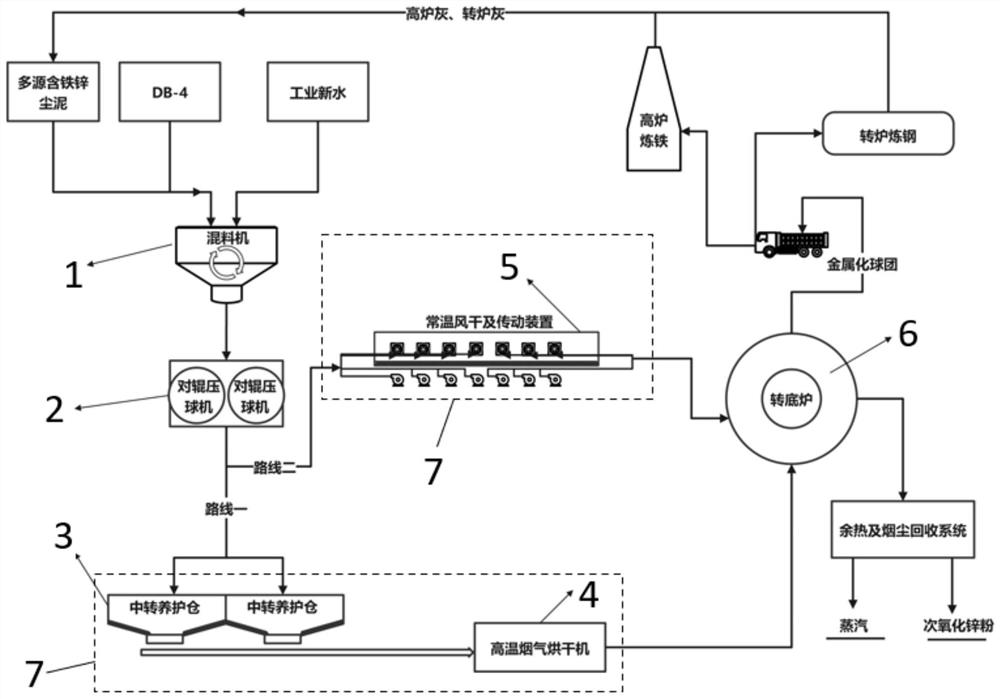

[0069] In this embodiment, the iron-containing zinc dust sludge resource utilization system of the present invention is used to process the iron-containing zinc dust sludge, wherein the maintenance and drying equipment adopts Figure 4 Transit curing bin and dryer shown.

[0070] As shown in Table 1, 14.7wt% of blast furnace ironmaking bag ash (blast furnace ash) in A steel plant, 30.5wt% of OG-LT mixed ash of converter steelmaking, 32.3wt% of OG-electric furnace mixed ash of electric furnace steelmaking, 5.5wt% of internal dust, 1.8wt% of cold rolling mud, 3.7wt% of coking plant dust removal raw material (CDQ powder), 2.3wt% of DB-4 type composite binder as binder. In DB-4 type composite binder, sodium-based bentonite is 30wt%, pregelatinized starch is 40wt%, and DB-X type base material is 30wt%; the pregelatinized starch can be pregelatinized corn starch or pregelatinized tapioca starch; DB-X type base material is mainly composed of sodium humate, solid sodium silicate, car...

Embodiment 2

[0081] In this embodiment, the iron-containing zinc dust sludge resource utilization system of the present invention is used to process the iron-containing zinc dust sludge, wherein the maintenance and drying equipment adopts Figure 4 Transit curing bin and dryer shown.

[0082] As shown in Table 3, with 26wt% blast furnace ironmaking bag ash (blast furnace secondary ash), 51.9wt% converter steelmaking OG mud, 20wt% internal dust removal ash (environmental ash) in B steel plant, 1.9% DB-4 type composite binder is an additive. The DB-4 type composite binder contains 40wt% sodium bentonite, 40wt% pregelatinized starch and 20wt% DB-X type base material; the pregelatinized starch can be pregelatinized corn starch or pregelatinized tapioca starch; DB-X type base material is mainly composed of sodium humate, solid sodium silicate, carboxymethyl cellulose and sodium polyacrylate. The raw materials are digested, dried and other pretreatments, mixed with DB-4 type composite binder, ...

Embodiment 3

[0093] In the present embodiment, the iron-containing zinc dust sludge resource utilization system of the present invention is used to process the iron-containing zinc dust sludge, wherein the maintenance and drying equipment adopts such as Figure 5 Air drying and turning unit shown.

[0094] As shown in Table 5, with 14wt% blast furnace ironmaking bag ash (blast furnace ash), 66.2wt% converter steelmaking OG-LT mixed ash, 16wt% internal dust removal ash (environmental ash), 2wt% Coking plant dust removal raw material (CDQ), with 1.8wt% DB-4 type composite binder as additive. The DB-4 type composite binder contains 40wt% sodium bentonite, 50wt% pregelatinized starch and 10wt% DB-X type base material; the pregelatinized starch can be pregelatinized corn starch or pregelatinized tapioca starch; DB-X type base material is mainly composed of sodium humate, solid sodium silicate, carboxymethyl cellulose and sodium polyacrylate. The raw materials are fully mixed with DB-4 type co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com