Novel sulfonated polybenzimidazole copolymer, crosslinked membrane, preparation method and application thereof

A technology for sulfonating polybenzimidazole and polybenzimidazole, which is applied in the parts of fuel cells, renewable fuel cells, etc., can solve the problems of difficulty in precise control of crosslinking density, reduction in proton conductivity, and difficulty in popularization and application. Achieve the effects of excellent chemical stability, high mechanical strength and thermal stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

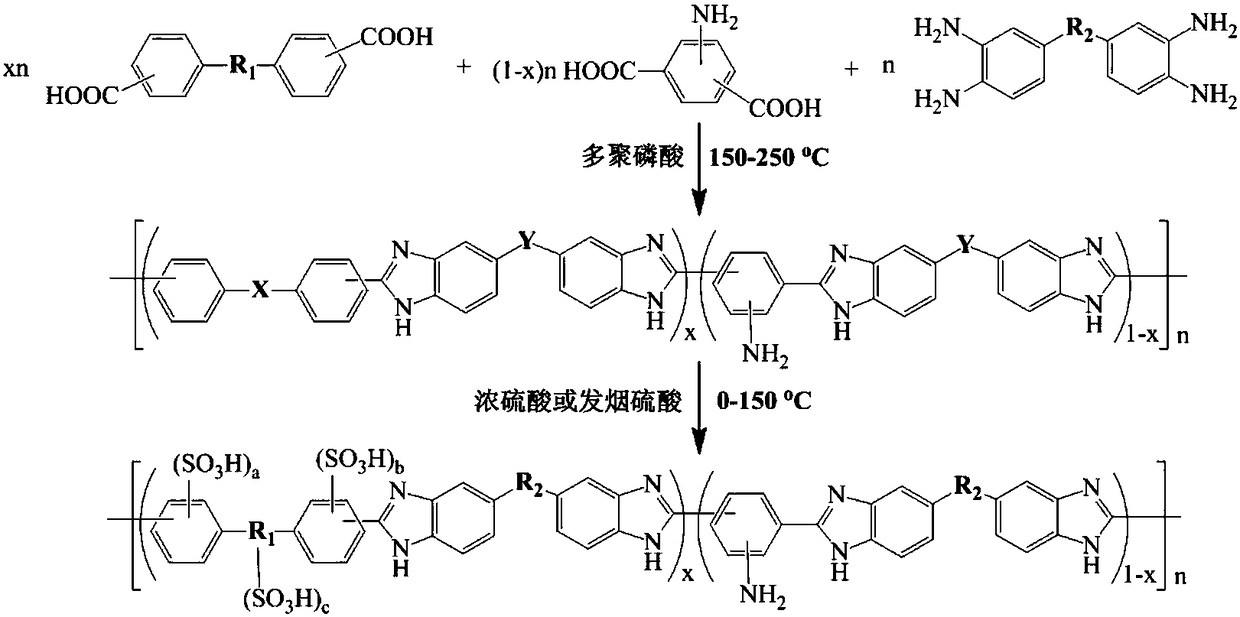

[0035] Example 1: A side sulfonated polybenzimidazole SOPBI-NH 2 Synthesis of (9 / 1)

[0036] first step:

[0037]Add 100g polyphosphoric acid, 2.14g (10mmol) 3,3'-diaminobenzidine (DAB), 2.3220g (9mmol) 4 , 4′-diphenyl ether dicarboxylic acid (DCDPE) and 0.1812g (1mmol) 5-aminoisophthalic acid (APTA), under a nitrogen atmosphere, first heat up to 150°C for 2h, then continue to heat up to 190°C for 20h . After the reaction, the polymer solution was poured into 300g of ice water, and the precipitated product was washed three times with deionized water, then soaked in 2wt% sodium bicarbonate solution for one day, filtered with suction, and the obtained solid product was washed with deionized water until neutral, and finally dried at 60°C under vacuum for 20h.

[0038] Step two:

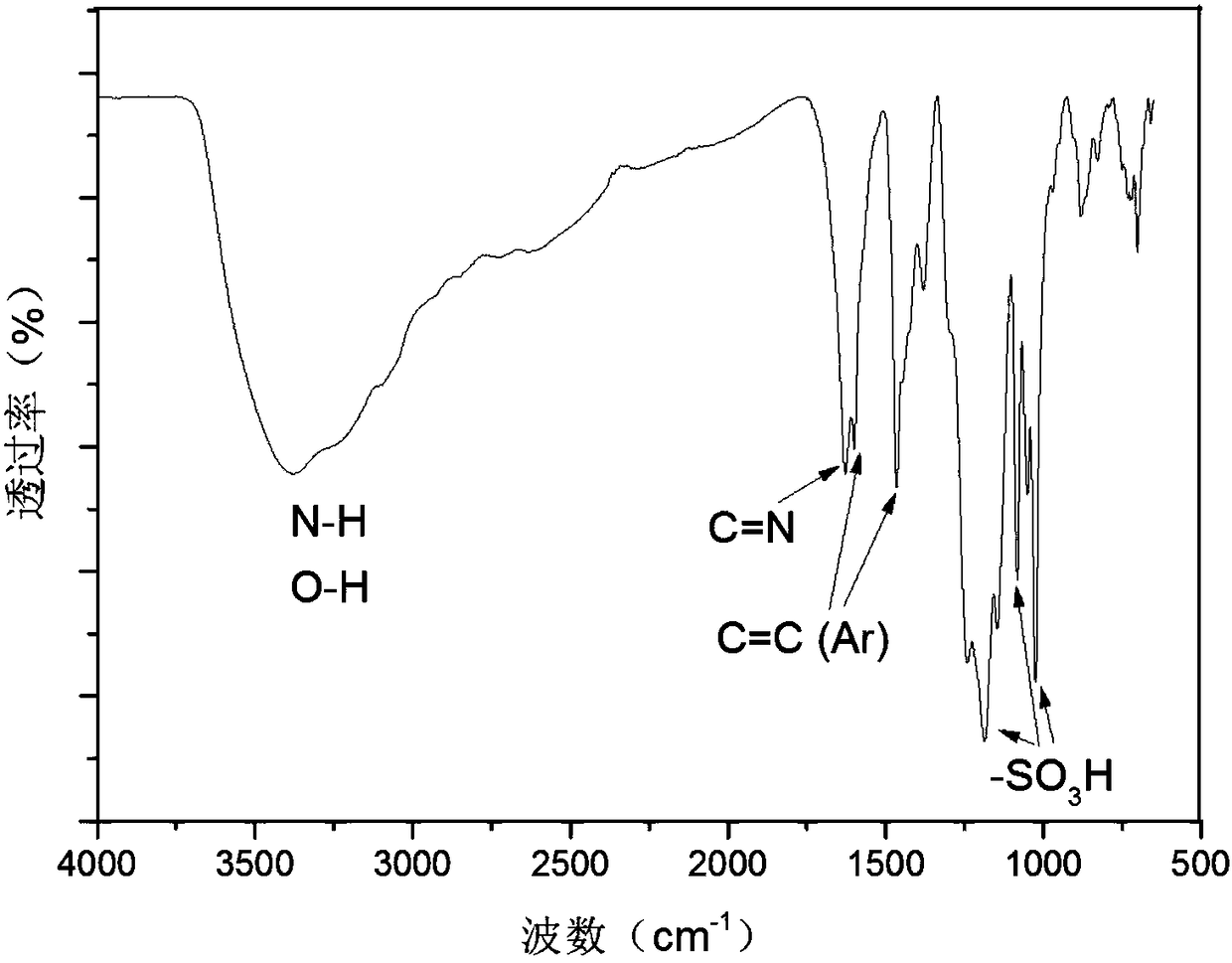

[0039] Under ice bath and nitrogen protection, 2 g of the product prepared by the first step reaction and 20 mL of fuming sulfuric acid (20% SO 3 ), stirred for 0.5 hours. The ice bath was removed...

Embodiment 2

[0041] Example 2: A side sulfonated polybenzimidazole SOPBI-NH 2 Synthesis of (5 / 1)

[0042] Control the molar ratio of 4,4'-diphenyl ether dicarboxylic acid (DCDPE) to 5-aminoisophthalic acid (APTA) to be 5:1, and the rest of the operating steps and conditions are exactly the same as in Example 1 to obtain DCDPE and APTA Sulfonated polybenzimidazole copolymer SOPBI-NH with a unit ratio of 5:1 2 (5 / 1). Its ion exchange capacity was measured by titration method to be 2.87meq / g.

Embodiment 3

[0043] Example 3: A polybenzimidazole SOPBI-NH containing side amino groups 2 Synthesis of (4 / 1)

[0044] Control the molar ratio of 4,4'-diphenyl ether dicarboxylic acid (DCDPE) to 5-aminoisophthalic acid (APTA) to be 4:1, and the rest of the operating steps and conditions are exactly the same as in Example 1 to obtain DCDPE and APTA Sulfonated polybenzimidazole copolymer SOPBI-NH with a unit ratio of 4:1 2 (4 / 1). Its ion exchange capacity was measured by titration method to be 2.76meq / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com