Synthesis and application method of composite function resin for selectively removing nitrate and phosphate at same time

A technology with complex functions and synthetic methods, applied in chemical instruments and methods, water/sludge/sewage treatment, adsorption water/sewage treatment, etc., can solve problems such as little consideration of competitive adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

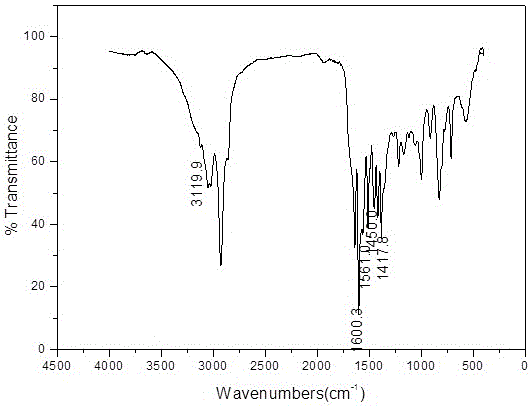

Image

Examples

Embodiment 1

[0025] Synthesis of Composite Functional Resin for Simultaneous and Selective Removal of Nitrate and Phosphate

[0026] (1) At room temperature, mix and dissolve 7g sodium chloride, 8g sodium carbonate, 2g sodium sulfate, 20g magnesium sulfate and 8g gelatin in 500mL water to make an aqueous phase;

[0027] (2) Mix 12g of chloromethylstyrene, 15g of 4-vinylpyridine, 3g of divinylbenzene, 18g of toluene, 14g of gasoline, 2g of liquid wax, 0.15g of benzoyl peroxide and 0.4g of azobisisobutyronitrile to obtain The organic phase of the polymerization reaction, that is, the oil phase;

[0028] (3) Add the water phase to a three-necked round-bottomed flask, heat up to 50°C and add 4 drops of methylene blue, then add the oil phase to the three-necked flask, stir to disperse the oil phase evenly, and continue at a heating rate of 5°C / min Heat up to 75°C for 2 hours, then raise the temperature to 80°C for 2 hours, stop the reaction, then cool down to room temperature, filter the reactio...

Embodiment 2

[0032] Synthesis of Composite Functional Resin for Simultaneous and Selective Removal of Nitrate and Phosphate

[0033] (1) At room temperature, mix and dissolve 10g of sodium chloride, 15g of sodium carbonate, 5g of sodium sulfate, 18g of magnesium sulfate and 8g of gelatin in 500mL of water to make an aqueous phase;

[0034] (2) Mix 13g of chloromethylstyrene, 14g of 4-vinylpyridine, 5g of divinylbenzene, 20g of toluene, 15g of gasoline, 2g of liquid wax, 0.35g of benzoyl peroxide and 0.20g of azobisisobutyronitrile to obtain The organic phase of the polymerization reaction, that is, the oil phase;

[0035] (3) Add the water phase to a three-necked round-bottomed flask, heat up to 50°C and add 5 drops of methylene blue, then add the oil phase to the three-necked flask, stir to disperse the oil phase evenly, and continue at a heating rate of 5°C / min Heat up to 75°C for 2 hours, then raise the temperature to 80°C for 2 hours, then stop the reaction, then cool down to room tem...

Embodiment 3

[0039] Synthesis of Composite Functional Resin for Simultaneous and Selective Removal of Nitrate and Phosphate

[0040] (1) At room temperature, mix and dissolve 15g of sodium chloride, 9g of sodium carbonate, 8g of sodium sulfate, 20g of magnesium sulfate and 10g of gelatin in 500mL of water to make an aqueous phase;

[0041] (2) Mix 10g of chloromethylstyrene, 9g of 4-vinylpyridine, 12g of divinylbenzene, 10g of toluene, 20g of gasoline, 2g of liquid wax, 0.20g of benzoyl peroxide and 0.32g of azobisisobutyronitrile to obtain The organic phase of the polymerization reaction, that is, the oil phase;

[0042] (3) Add the water phase to a three-necked round-bottom flask, heat up to 45°C and add 6 drops of methylene blue, then add the oil phase to the three-necked flask, stir to disperse the oil phase evenly, and continue at a heating rate of 5°C / min. Heat up to 75°C for 2 hours, then raise the temperature to 80°C for 2 hours, stop the reaction, then cool down to room temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com