Acid and alkali resistant rubber material

A technology of rubber material and acid and alkali resistance, applied in the field of acid and alkali resistance rubber materials, can solve the problems of acid and alkali corrosion of pipelines and storage equipment, poor ozone aging resistance, waste of rubber resources, etc. The effect of improving corrosion resistance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

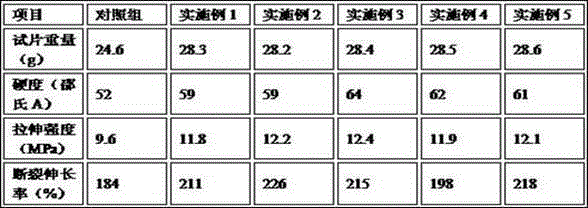

Examples

Embodiment 1

[0016] An acid and alkali resistant rubber material, made of the following raw materials in parts by weight: 15 parts of nitrile rubber, 30 parts of latex reclaimed rubber, 20 parts of porous powder quartz, 15 parts of N326 carbon black, 5 parts of titanate coupling agent 5 parts, 5 parts of silicone resin, 3 parts of sulfur, 5 parts of flow modifier, 2 parts of dibutyltin dilaurate.

Embodiment 2

[0018] An acid and alkali resistant rubber material, made of the following raw materials in parts by weight: 10 parts of silicone rubber, 10 parts of butyl reclaimed rubber, 28 parts of EPDM reclaimed rubber, 18 parts of porous powder quartz, 15 parts of N330 carbon black 4 parts, titanate coupling agent 4 parts, silicone resin 8 parts, sulfur 2 parts, flow modifier 3 parts, tert-butyl peroxybenzoate 2 parts.

Embodiment 3

[0020] An acid and alkali resistant rubber material, made of the following raw materials in parts by weight: 25 parts of chloroether rubber, 25 parts of nitrile reclaimed rubber, 15 parts of porous powder quartz, 15 parts of N234 carbon black, titanate coupling agent 5 parts, 8 parts of silicone resin, 3 parts of sulfur, 3 parts of flow modifier, 1 part of dibutyltin dilaurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com