Health dry and comfortable sanitary towel with antisepsis, ventilating cool and refreshing surface

A cool, body-surface technology, applied in the field of sanitary products, can solve the problems of lightness, thinness, penetration and weak bonding points without theoretical guidance, and achieve a solid entanglement, not easy to absorb water, and good hygiene. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

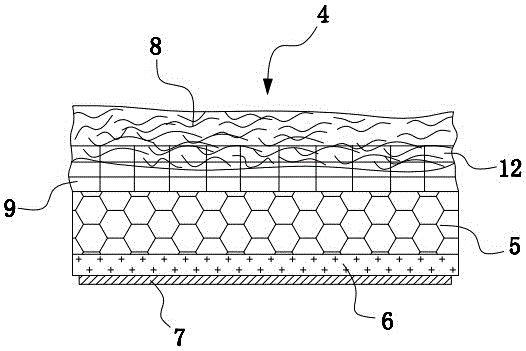

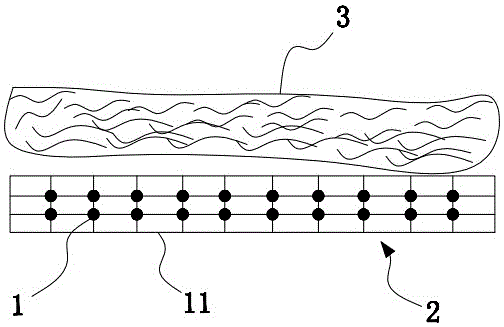

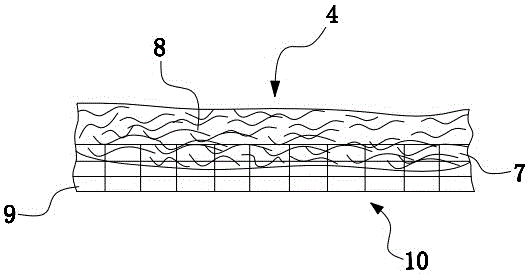

[0050] The preparation of false bonded spunbonded fiber web 2 is one of key points of the present invention, and false bonded spunbonded fiber web 2 refers to that when the bonding point 1 of the spunbonded fiber web is subjected to tensile force or impact force, the bonded Point 1 can be disassembled without fiber breakage. That is to say, the bonding force produced by the bonding point 1 to the fiber is smaller than the strength of the fiber itself. The main point of preparing the fiber web is that when the spun fiber web is hot-rolled, low-temperature and low-pressure hot-rolling is adopted, so that the fibers at the rolling point are not completely melted. Specifically, for polyester fiber webs, the hot-rolling temperature should be controlled at 180-200°C; for nylon fiber webs, the hot-rolling temperature should be controlled at 160-180°C; for polypropylene fiber webs, the hot-rolling temperature should be controlled at 80~110℃, the hot rolling pressure is 1 / 3~3 / 4 of the...

Embodiment 1

[0076] Firstly, 0.5% of the total weight of the polyester modulus-reducing masterbatch is evenly added to the polyester spinning chip, and then the screw spinning machine is heated, mixed, metered, and spun, and the surface of the polyester fiber filament is evenly attached to the hydrophilic by impregnation. The hydrophilic agent is a polyester or polyether compound solvent containing a hydrophilic group, and then stretched, separated, and laid to form a polyester spun fiber web, and the weight is controlled at 12 grams / m 2 . Then carry out low-temperature, low-pressure hot-rolling bonding to the spun fiber web, and the hot-rolling temperature should be controlled at 180° C.; the hot-rolling pressure is 0.9 MPa of conventional hot-rolling pressure. Simultaneously lay a carded fiber web 2 online, the composition is 80% viscose staple fiber, 10% chitosan fiber and 10% mint fiber, the specification is 1.5 denier × 51mm, and the gram weight is 20 g / m 2 , using cross-stacking. S...

Embodiment 2

[0078] First, 0.5% of the total weight of the polyester modulus-reducing masterbatch is evenly added to the polyester spinning chips. Then, it is heated, mixed, metered, and spun by a screw spinning machine, and the surface of the polyester fiber filament is evenly adhered to a hydrophilic agent by dipping. The hydrophilic agent is a polyester or polyether compound solvent containing a hydrophilic group, and then Stretching, splitting, and laying to form a polyester spinning fiber web, the weight is controlled at 15 grams / m 2 . Then carry out low-temperature, low-pressure hot-rolling bonding to the spun fiber web, and the hot-rolling temperature should be controlled at 200° C.; the hot-rolling pressure is 0.9 MPa of conventional hot-rolling pressure. Simultaneously lay a carded fiber web 2 online, the composition is 80% viscose staple fiber, 10% chitosan fiber and 10% mint fiber, the specification is 1.5 denier × 51mm, and the gram weight is 18 g / m 2 , using cross-stacking, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com