A kind of nano-titanium oxide modified organic silicon adhesive and preparation method thereof

A technology of nano-titanium oxide and silicone, applied in adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve problems such as poor self-cleaning performance and poor weather resistance of silicone adhesives. achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

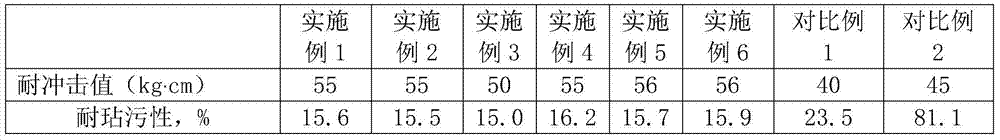

Examples

Embodiment 1

[0034] A nano-titanium oxide modified silicone adhesive, in parts by weight, comprises the following components:

[0035] 30 parts of silicone resin, 5 parts of polyimide,

[0036] 3 parts of silicone oil, 1.5 parts of nano-titanium oxide,

[0037] 0.5 parts of basalt fiber, 2 parts of polyethylene wax,

[0038] 1 part silicone adhesion promoter.

[0039] Its preparation method comprises the following steps:

[0040] (1) Mix and stir nano-titanium oxide, basalt fiber, silicone oil, and polyethylene wax evenly, transfer to an autoclave, and process at 150° C. for 2 hours to obtain a mixed slurry A;

[0041] (2) Mix silicone resin, polyimide, silicone adhesion promoter and the mixed slurry A obtained in step (1), ultrasonicate for 2 hours at a power of 500W, and then ball mill for 10 hours to obtain nano-titanium oxide modified Silicone adhesive.

Embodiment 2

[0043] A nano-titanium oxide modified silicone adhesive, in parts by weight, comprises the following components:

[0044] 50 parts of silicone resin, 8 parts of polyimide,

[0045] 6 parts of silicone oil, 3 parts of nano-titanium oxide,

[0046] 1 part of basalt fiber, 5 parts of polyethylene wax,

[0047] Silicone adhesion promoter 2 parts.

[0048] Its preparation method comprises the following steps:

[0049] (1) Mix and stir nano-titanium oxide, basalt fiber, silicone oil, and polyethylene wax evenly, transfer to an autoclave, and process at 180° C. for 5 hours to obtain a mixed slurry A;

[0050] (2) Mix silicone resin, polyimide, silicone adhesion promoter and the mixed slurry A obtained in step (1), ultrasonicate for 5 hours at a power of 1000W, and then ball mill for 20 hours to obtain nano-titanium oxide modified Silicone adhesive.

Embodiment 3

[0052] A nano-titanium oxide modified silicone adhesive, in parts by weight, comprises the following components:

[0053] 35 parts of silicone resin, 6 parts of polyimide,

[0054] 4 parts of silicone oil, 2 parts of nano-titanium oxide,

[0055] 0.6 parts of basalt fiber, 3 parts of polyethylene wax,

[0056] 1.2 parts of silicone adhesion promoter.

[0057] Its preparation method comprises the following steps:

[0058] (1) Mix and stir nano-titanium oxide, basalt fiber, silicone oil, and polyethylene wax evenly, transfer to an autoclave, and process at 160° C. for 3 hours to obtain a mixed slurry A;

[0059] (2) Mix silicone resin, polyimide, silicone adhesion promoter and the mixed slurry A obtained in step (1), ultrasonicate for 3 hours at a power of 600W, and then ball mill for 12 hours to obtain nano-titanium oxide modified Silicone adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com