Method for growing nanometer particles on substrate

A nanoparticle and nanoparticle technology, which is applied in the field of nanoparticle preparation, can solve the problems of increasing preparation cost and increasing process steps, and achieve uniform particle size, simplify the preparation process, and avoid agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Take 0.1 mmol of cobalt acetylacetonate and 10 ml of alcohol, dissolve cobalt acetylacetonate in alcohol, mix well with ultrasonic assistance, and let stand for 10 minutes to obtain cobalt acetylacetonate solution;

[0035] (2) drop the cobalt acetylacetonate solution onto a clean glass sheet, and let it stand still to evaporate the alcohol, so that the cobalt acetylacetonate is evenly dispersed on the surface of the glass sheet;

[0036] (3) Put the glass sheet into the constant temperature zone of the tube furnace, raise the temperature to 300°C at a rate of 10°C / min, calcinate in an oxygen atmosphere, and keep it for 5min to obtain Co 2 o 3 of nanoparticles.

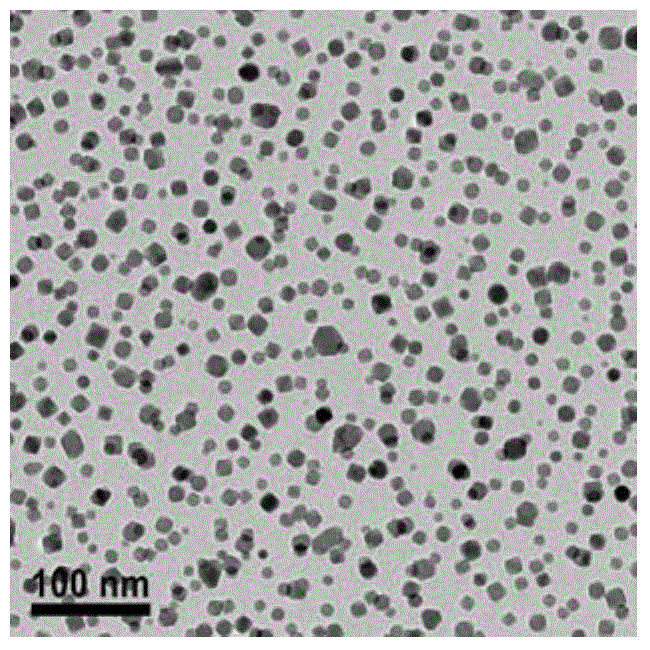

[0037] figure 1 is the Co obtained above 2 o 3 The TEM image of the nanoparticles, from which it can be seen that the nanoparticles are discretely distributed, uniformly dispersed, and uniform in particle size, with a particle size of 5-20nm.

Embodiment 2

[0039] (1) Take 0.1 mmol of cobalt acetylacetonate and platinum acetylacetonate, and 20 ml of alcohol, dissolve cobalt acetylacetonate and platinum acetylacetonate in alcohol, mix them uniformly with ultrasonic assistance, and let stand for 10 minutes to obtain a mixed solution;

[0040] (2) Take the mixed solution and drop it on a clean glass sheet, and let it stand still to evaporate the alcohol, so that cobalt acetylacetonate and platinum acetylacetonate are evenly dispersed on the surface of the glass sheet;

[0041] (3) put the glass piece into the constant temperature zone in the tube furnace for calcination, the calcination process is as follows: first feed inert gas N 2 , He or Ar to remove the air, and then inert gas and H 2 The mixed gas flow rate is 20ml / min, and then the temperature is raised to 500°C at a rate of 10°C / min, kept for 5min, and finally cooled to room temperature under the protection of the mixed atmosphere to obtain CoPt nanoparticles.

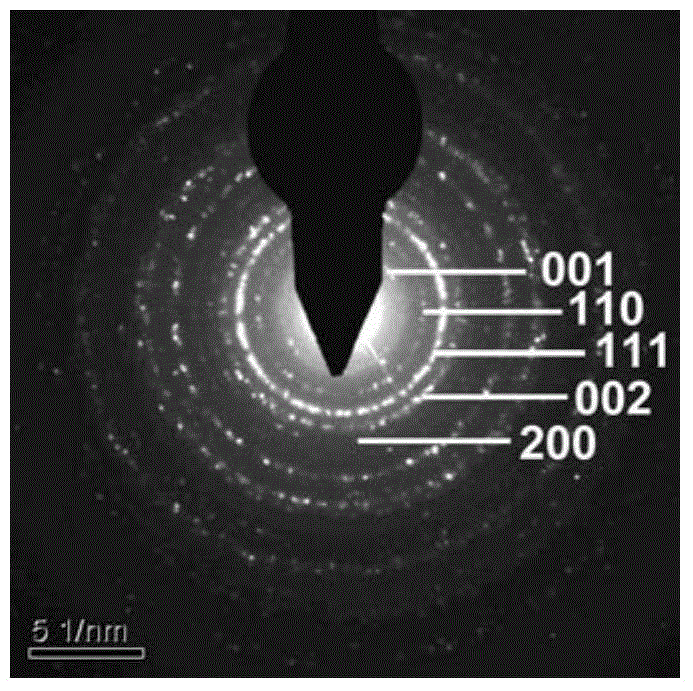

[0042] figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com