Method for manufacturing ultra-thin nanocrystalline metal strip

A technology of metal poles and nanocrystals, applied in the field of rolling, can solve problems such as difficult and low-cost production, limited research and application, and achieve the effects of continuous, uniform grain refinement, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

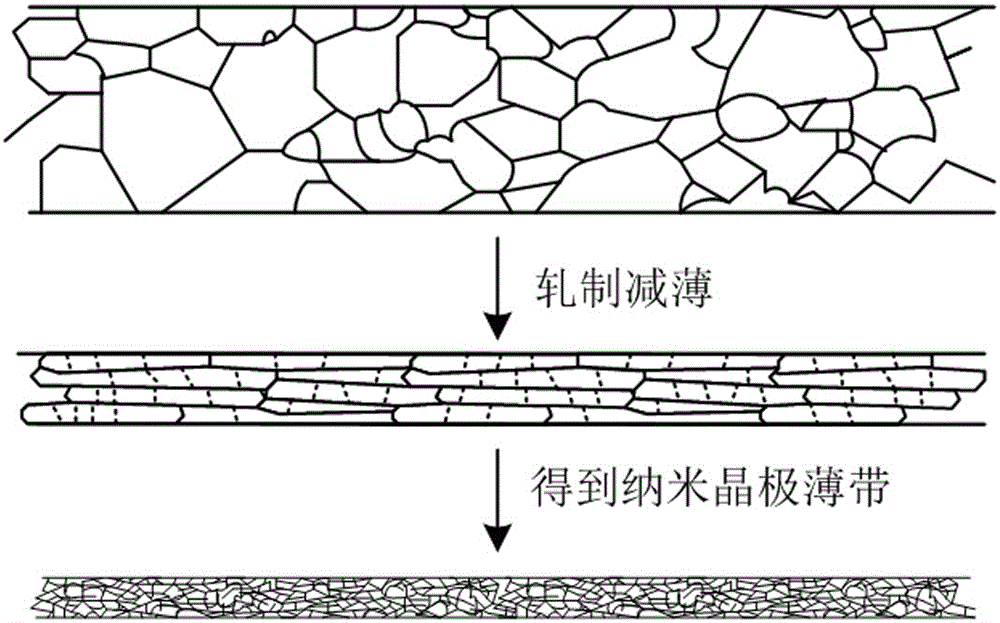

[0028] The cumulative reduction coefficient of the preparation method of the ultra-thin nanocrystalline metal strip of the present invention is greater than or equal to 40.0.

[0029] The transmission electron microscope used in the present invention is TecnaiG 2 20.

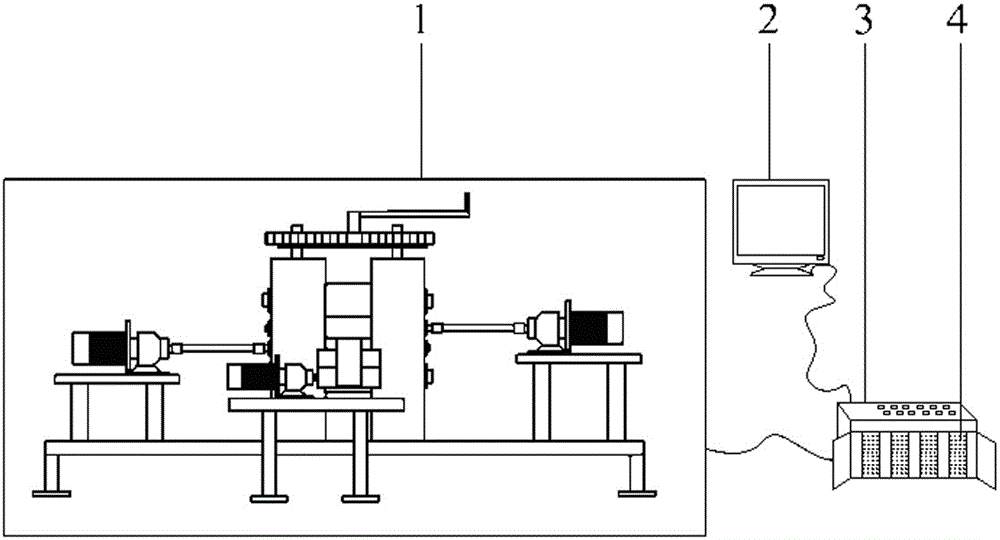

[0030] The structure of the preparation device of the nanocrystalline metal extremely thin strip of the present invention is as follows: figure 1 As shown, the asynchronous ultra-thin strip mill 1 sets the rolling speed, the variable speed ratio and the variable speed ratio adjustment step through the control system, and adjusts the variable speed ratio online through the control system; the control system includes a main control computer 2, PLC4 and console 3.

[0031] The maximum rolling speed of the asynchronous ultra-thin strip mill used in the embodiment of the present invention is 130mm / s, and the maximum rolling force is 500kN.

Embodiment 1

[0033] 1. The raw material used is a Q195 steel strip with a thickness of 350 μm and a width of 80 mm. The composition is C0.06~0.12%, Mn0.25~0.50%, Si≤0.30%, S≤0.05%, P≤0.045% by weight, The rest is Fe, the grain size is 12μm, and the yield strength of the raw material is 195MPa; start the power supply of the rolling mill system, and pass the Q195 steel strip through the gap between the upper and lower work rolls, and roll it onto the two reels;

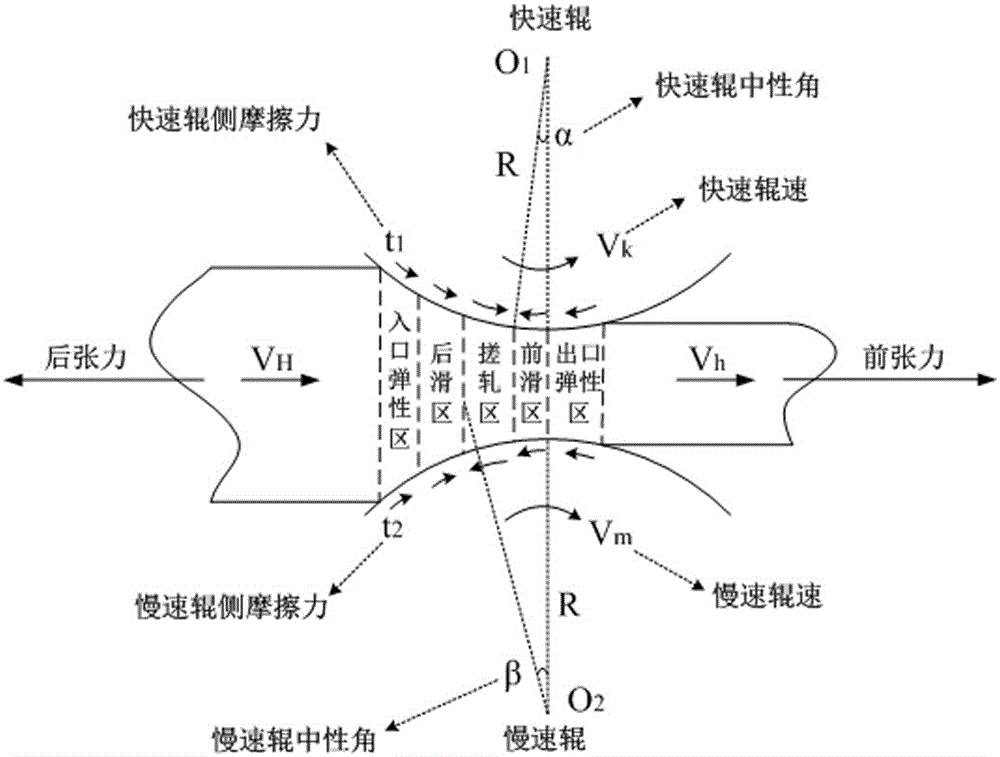

[0034] 2. Set the rolling speed, variable speed ratio, variable speed ratio adjustment step, pre-compression force and front and rear tensile stress of the asynchronous ultra-thin strip rolling mill; the rolling speed is 50mm / s, which is 38.5% of the maximum rolling speed of the rolling mill , the variable speed ratio is 1.0, and the variable speed ratio adjustment step is 0.01; the front and rear tensile stress is 70MPa, which is 35.9% of the yield strength of the rolled piece raw material, and the pre-compression force is 100kN, wh...

Embodiment 2

[0040] Method is with embodiment 1, and difference is:

[0041] (1) The raw material used is a copper strip with a thickness of 1000μm and a width of 50mm, the grade is T2, and the composition contains Cu99.90%, Ag0.022%, Bi0.0005%, Sb0.001%, As0.002%, by weight percentage, Fe0.002%, Ni0.009%, Pb0.005%, Sn0.002%, S0.005%, Zn0.008%, O0.025%, the grain size is 14μm, and the yield strength of the raw material is 70MPa;

[0042] (2) Set the rolling speed to 120mm / s, which is 92.3% of the maximum rolling speed of the rolling mill, the variable speed ratio to 1.2, and the variable speed ratio adjustment step to 0.02; the front and rear tensile stress is 40MPa, which is the yield strength of the rolled piece raw material 57.1%, the pre-compression force is 130kN, which is 26.0% of the maximum rolling force of the rolling mill;

[0043] (3) After one pass of rolling, reset the rolling speed to 120mm / s, which is 92.3% of the maximum rolling speed of the rolling mill, the different spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com