Heat treatment technology for 7-series high-strength aluminum alloy

An aluminum alloy, high-strength technology, applied in the heat treatment process of 7-series high-strength aluminum alloys, can solve the problem that the comprehensive mechanical properties of the material are not significantly improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A heat treatment process for a 7-series high-strength aluminum alloy, taking 7075 alloy as an example, the steps are as follows:

[0030] Table 17 Chemical composition of materials (mass fraction, %)

[0031]

[0032] Solution treatment

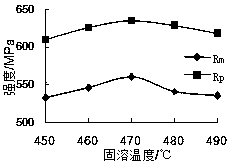

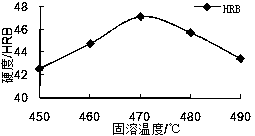

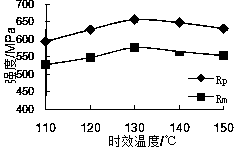

[0033] The solid solution is carried out in the box-type resistance furnace SX2-12-10. The furnace is installed at room temperature and the heating method is raised with the temperature of the furnace, and a thermocouple is introduced for temperature monitoring. At 470°C and holding for 60 minutes, the peak value appeared, and the tensile strength, yield strength and hardness reached 635MPa, 560MPa and 46.5HRB respectively. The strength and microhardness variation curve of the alloy at the solution temperature, such as figure 1 , figure 2 shown, where R m is the yield strength, R p is the tensile strength. After solution treatment, the sample was placed in 0.32wt% polyethylether aqueous solution and rapidly cooled to room tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com