Carbon material for using as catalyst carrier

A technology of catalyst carrier and carbon material, applied in the direction of catalyst carrier, catalyst activation/preparation, physical/chemical process catalyst, etc., can solve problems such as difficulty in use, and achieve the effects of accelerating popularization, reducing usage, and excellent durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

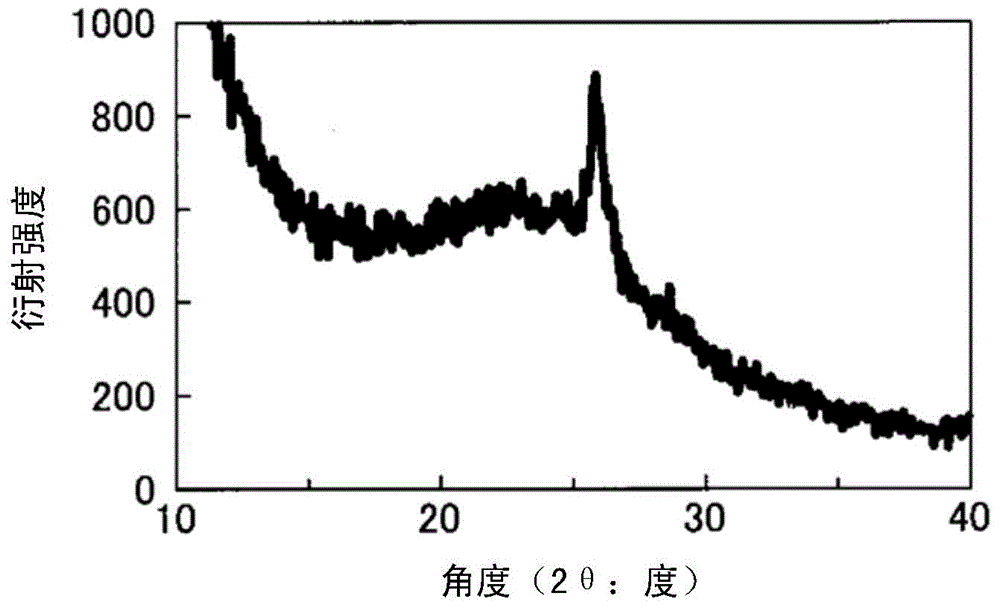

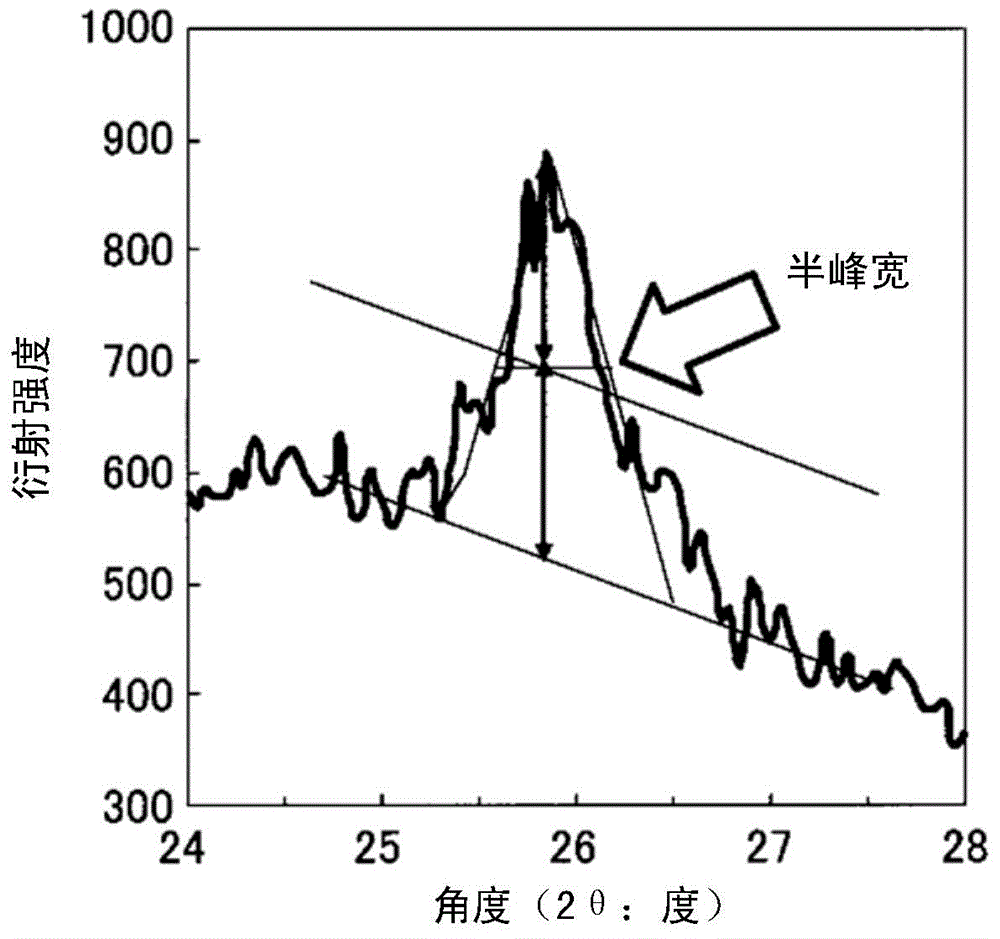

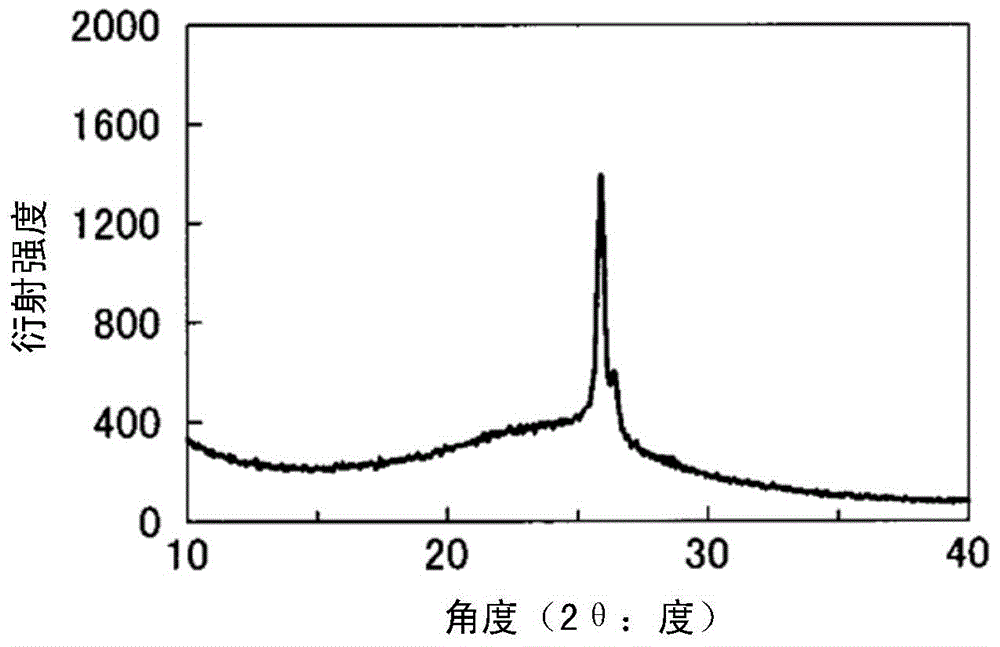

Image

Examples

Embodiment 1

[0064] First, 150 mL of an ammonia solution (1.9%) containing silver nitrate at a concentration of 1.1 mol% was prepared in a flask, and residual oxygen was removed with an inert gas such as argon or dry nitrogen. The solution was stirred, and acetylene gas was blown into the solution at a flow rate of 25 mL / min for about 4 minutes while the ultrasonic vibrator was immersed in the liquid to impart vibration.

[0065] A solid substance of silver acetylene is produced in the solution, and after the silver acetylide is completely precipitated, the precipitate is filtered with a membrane filter. When filtering, the precipitate was washed with methanol and some ethanol was added to impregnate the precipitate with the methanol. The silver acetylene precipitate immersed in methanol was rapidly heated to a temperature of 160° C. to 200° C. in a vacuum dryer, and kept at a constant temperature for 20 minutes (first heat treatment). During holding, a nanoscale explosive reaction occurs...

Embodiment 2

[0068] Except having set the temperature of the 2nd heat treatment to 1800 degreeC, it processed similarly to Example 1, and obtained the carbon material.

Embodiment 3

[0070] A carbon material was obtained in the same manner as in Example 1 except that the temperature of the second heat treatment was set to 2000° C. and the treatment time was set to 0.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com