Preparation method and application of dna double helical carbon nanofiber and preparation method of lithium ion battery negative electrode material

A lithium-ion battery, nano-carbon fiber technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve problems such as application limitations, stay in the research stage, etc., to improve the ability to resist damage and improve the effect of comprehensive electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific embodiments.

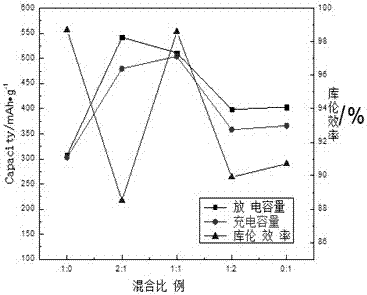

[0030] The application of the DNA double-helix nano-carbon fiber in the lithium ion battery of the present invention is to apply the DNA double-helix nano-carbon fiber as the negative electrode material of the lithium-ion battery to the lithium-ion battery.

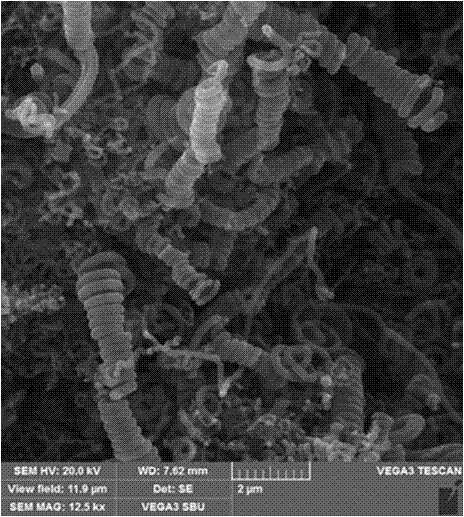

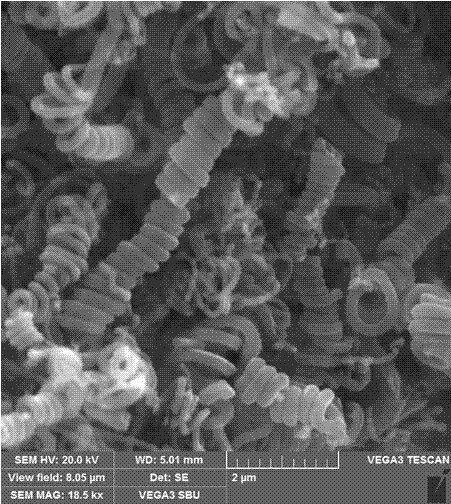

[0031] 1. The present invention prepares DNA double helical carbon nanofibers by the following method:

[0032] 1) Take an appropriate amount of catalyst precursor copper tartrate in a porcelain boat, then place the porcelain boat in a quartz tube with good airtightness, and inject Ar gas into the quartz tube at a speed of 60mL / min to exhaust the Air;

[0033] 2) Heat the quartz tube from room temperature to 210°C, and then keep it at this temperature for 30 minutes;

[0034] 3) After the heat preservation in step 2), raise the temperature of the quartz tube to 580°C, and then heat it at this temperature fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com