Rapid analysis method of lead in gold mud

A rapid analysis and gold mud technology, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problems of high valence state of gold ions, difficult separation, encapsulation and adsorption, etc. , to achieve the effects of improving detection efficiency, quick and easy operation, and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment further illustrate the present invention.

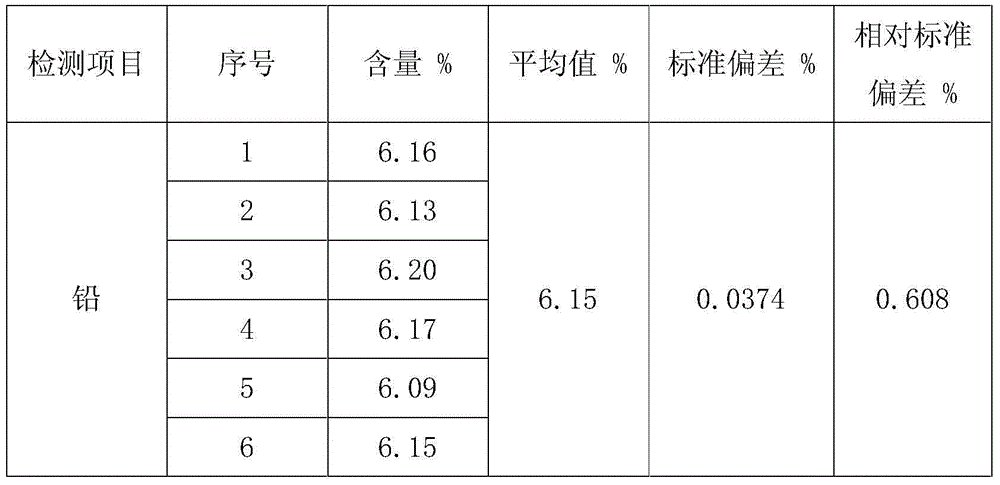

[0030] 1. Examples of analysis methods.

[0031] Main reagents: Reagents and standard solutions are basically the same as the requirements in GB / T7739.5, and the different parts will be explained separately.

[0032] Sample pretreatment: Put the prepared gold mud sample (hereinafter referred to as the sample) into a constant temperature drying oven, set the temperature at 105-110°C, and after drying to a constant weight, take it out and put it in a desiccator to cool to room temperature for later use. This process is mainly used to remove the moisture in the sample to ensure the accuracy of the capacity analysis results.

[0033] Analysis steps:

[0034] 1. Sample dissolution: Accurately weigh 0.2000g ~ 1.0000g sample into a 300mL beaker, moisten it with a little water, add 15mL nitric acid (1+1), cover with a watch glass, and heat to a slight boil on a hot plate. When there is no red-br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com