Method for producing thermostable type tin indium oxide in low resistance ratio

A technology of indium tin oxide film and low resistance, applied in the manufacture of circuits, electrical components, semiconductors/solid devices, etc. Changes and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, preferred embodiments of the present invention are listed and described in detail with accompanying drawings.

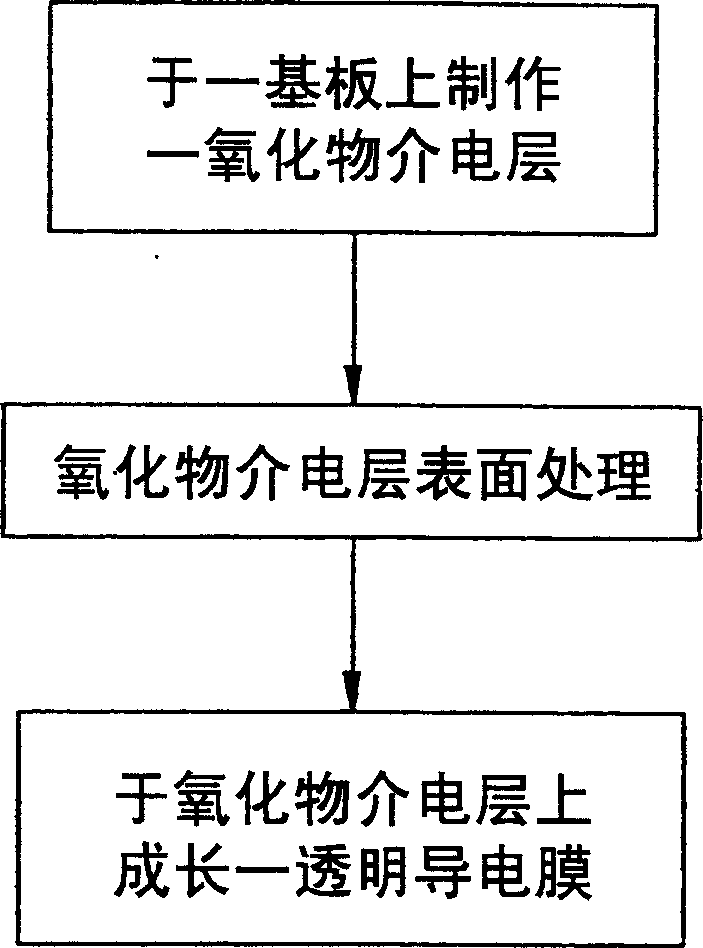

[0021] see figure 1 , 2 As shown, the thermally stable and low-resistance ratio indium tin oxide film manufacturing method of the present invention comprises the following steps:

[0022] a. Making an oxide dielectric layer:

[0023] First place a substrate 10 in a vacuum reaction chamber (not shown) of a sputtering system. The substrate 10 used in this embodiment consists of a transparent body 11 and a hard film 12 arranged on one side of the body 11. Composition (refer to figure 2 a), the aforementioned body 11 is made of plastic material, such as polyethylene terephthalate (PET), and the other side of the body 11 constitutes the surface 10a of the substrate 10; in addition, The substrate can also be composed of a hard film on both sides of the transparent body, and the surface of one of the hard films constitutes the surface of the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com