Effective sapphire fine grinding method and fine grinding solution

A sapphire and fine grinding technology, which is applied in the direction of grinding machine tools, grinding devices, polishing compositions containing abrasives, etc., can solve the problems of short service life and low grinding efficiency, so as to improve service life, avoid hard contact, and excellent penetration and cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

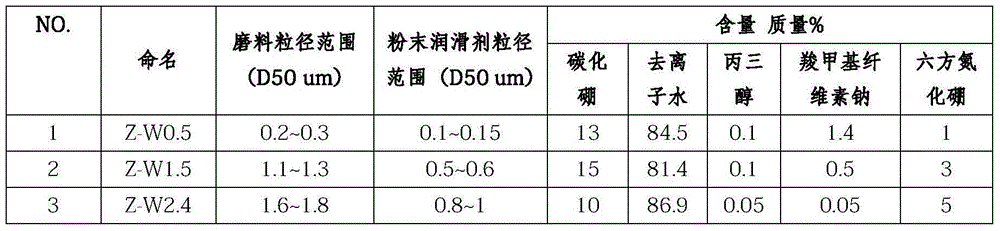

[0020] 1. Formula

[0021] In this embodiment, the sapphire fine grinding fluid includes ultra-fine high-hardness micropowder, powder lubricant, dispersant and deionized water. Among them, the ultra-fine high-hardness micropowder is preferably boron carbide as the abrasive of the fine grinding fluid, and the particle size is preferably W2.4, W1.5 and W0.5 standard micropowder, that is, the median particle size D50 is 1.6-1.8um, respectively. 0.5~0.6um and 1.1~1.3um. Configure according to the formula listed in Table 1.

[0022] Table 1. The formula of refined grinding liquid provided by the present invention

[0023]

[0024] 2. Grinding method

[0025] Refined liquid is used as it is without the addition of water or aqueous solution for dilution. The fine grinding fluid is transported into the grinder, so that the grinding disc is in contact with the surface to be ground, and the surface to be ground and the grinding disc move relatively. The export port of the fine g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com