Preparation method of high-solid-content ester polycarboxylic acid water reducing agent

A technology of ester polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of increasing production cost, increasing concentration and separation steps, etc., and achieves the effects of cost saving, improving conversion rate and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

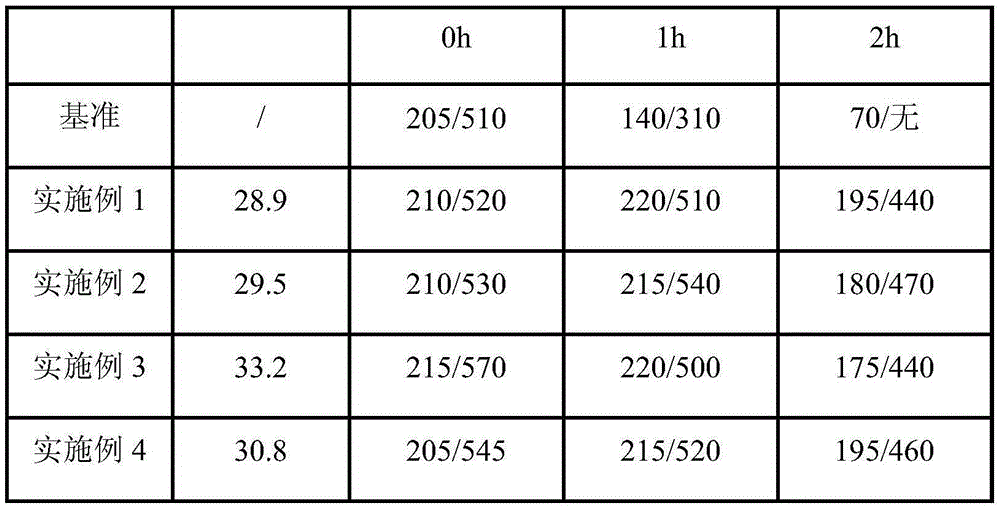

Embodiment 1

[0024] (1) Esterification and amidation reaction: in parts by weight, 120 parts of molecular weight are 1200 polyethylene glycol monomethyl ether and 50 parts of molecular weight are 2000 polyethylene glycol monomethyl ether, 7 parts of molecular weight are 500 Amino-terminated polyoxypropylene ether, 16 parts of methacrylic acid, 8.5 parts of methanesulfonic acid and 0.4 parts of mixed polymerization inhibitor were added to reactor A equipped with a condensing device, and kept at a constant temperature of 95°C under nitrogen protection React for 5 hours to obtain the first mixture containing polyethylene glycol monomethyl ether methacrylate, isoacryloyl polyoxypropylene ether amine monomer, and methacrylic acid; wherein: the mixed polymerization inhibitor is by weight Calculated as hydroquinone:p-hydroxyanisole=2:1, the following embodiments can also be the same.

[0025] (2) Copolymerization reaction: in parts by weight, place 80 parts of the first mixture obtained in step (...

Embodiment 2

[0028] (1) Esterification and amidation reaction: in parts by weight, 120 parts of molecular weight are 1200 polyethylene glycol monomethyl ether and 50 parts of molecular weight are 2000 polyethylene glycol monomethyl ether, 7 parts of molecular weight are 1200 Add amino-terminated polyoxypropylene ether, 50 parts of methacrylic acid, 11 parts of methanesulfonic acid and 1 part of mixed polymerization inhibitor into reactor A equipped with a condensing device, and keep the temperature at 120°C under the protection of nitrogen After reacting for 7 hours, the first mixture containing polyethylene glycol monomethyl ether methacrylate, isoacryloyl polyoxypropylene ether amine monomer and methacrylic acid was obtained.

[0029] (2) Copolymerization reaction: in parts by weight, place 80 parts of the first mixture obtained in step (1) in the reactor B; 70 parts of the first mixture are placed in the dripping device B1, and then add 3 parts of methyl methacrylate, 4 parts of hydroxy...

Embodiment 3

[0032] (1) Esterification and amidation reaction: in parts by weight, 120 parts of molecular weight are 2000 polyethylene glycol monomethyl ether and 50 parts of molecular weight are 3000 polyethylene glycol monomethyl ether, 7 parts of molecular weight are 500 Amino-terminated polyoxypropylene ether, 23 parts of methacrylic acid, 11 parts of p-toluenesulfonic acid and 0.8 parts of mixed polymerization inhibitor were added to reactor A equipped with a condensing device, under the protection of nitrogen, at 100 ° C After constant temperature reaction for 6 hours, the first mixture containing polyethylene glycol monomethyl ether methacrylate, isoacryloyl polyoxypropylene ether amine monomer and methacrylic acid was obtained.

[0033](2) Copolymerization reaction: in parts by weight, place 80 parts of the first mixture obtained in step (1) in the reactor B; 70 parts of the first mixture are placed in the dripping device B1, and then add 3 parts of hydroxypropyl acrylate, 3 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com