High-air-barrier-property multilayer-co-extrusion packaging film

A gas barrier, multi-layer co-extrusion technology, used in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of high manufacturing cost and poor gas barrier properties, reduce production costs, improve gas barrier performance, and improve market competition. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

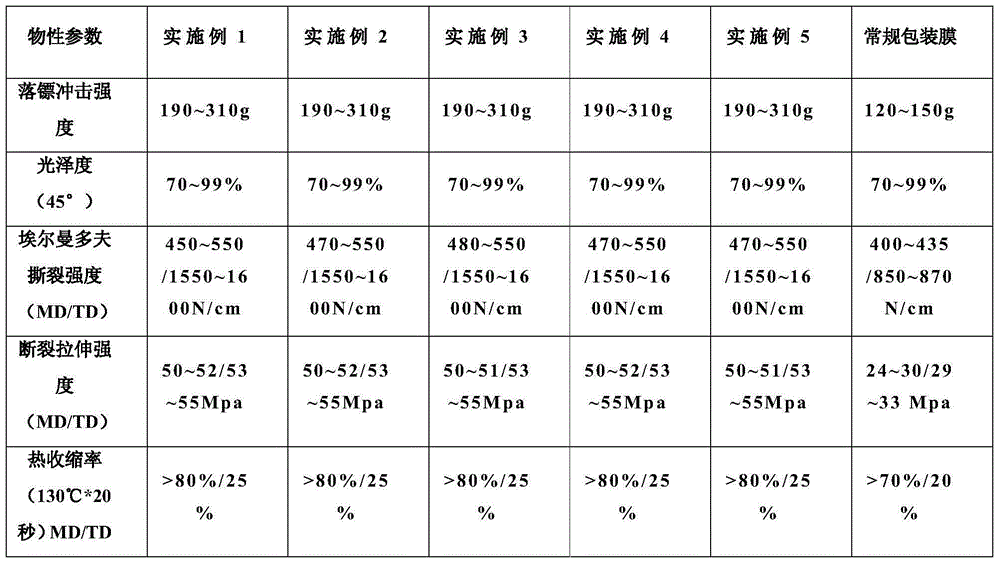

Examples

Embodiment 1

[0028] combine figure 1As shown, in the high gas barrier multilayer co-extruded packaging film of this embodiment, the thickness of the surface layer 1: 8 microns, the thickness of the inner layer 5 is 19 microns, the first core layer 2, the second core layer 3 and the third core layer 4 The thicknesses are all 3 microns, and the thickness of the adhesive layer 6 is 3 microns.

[0029] Raw materials for each layer, surface layer 1: polyamide 80kg; first core layer 2: polyamide 50kg; second core layer 3: ethylene-vinyl alcohol copolymer layer 100kg; third core layer 4: 98kg vinylidene chloride-malay Anhydride copolymer (melting point 150°C, density 1.7g / cm 3 ) and 2kg of epoxy soybean oil; inner layer 5: linear low density polyethylene 50kg, density 0.90g / cm 3 , the melt index is 0.35g / 10min; the raw materials of the adhesive layer 6 of each layer are the same, all are 5kg ethylene-vinyl acetate copolymer, and the density is 0.93g / cm 3 .

[0030] The raw materials of each l...

Embodiment 2

[0032] see figure 1 As shown, in the high gas barrier multilayer co-extruded packaging film of this embodiment, the thickness of the surface layer 1 is 9 microns, the thickness of the inner layer 5 is 20 microns, the thickness of the first core layer 2 is 3 microns, and the thickness of the second core layer 3 is 5 microns. The thickness of the third core layer 4 is 4 microns, and the thickness of the adhesive layer 6 is 4 microns.

[0033] Raw materials for each layer, surface layer 1: polyolefin 100kg in total, specifically 60kg ethylene-alpha olefin copolymer (alpha olefin is propylene), density is 0.88g / cm 3 , and 40kg of ethylene-methacrylic acid copolymer;

[0034] The first core layer 2: polyamide 40kg; the second core layer 3: ethylene-vinyl alcohol copolymer layer 80kg; the third core layer 4: 98kg vinylidene chloride-maleic anhydride copolymer (melting point 150 ° C, density 1.7 g / cm 3 ) and 2kg of epoxidized soybean oil; inner layer 5: a mixture of 40kg of linear...

Embodiment 3

[0037] see figure 1 As shown, in the high gas barrier multilayer co-extruded packaging film of this embodiment, the thickness of the surface layer 1: 10 microns, the thickness of the inner layer 5 is 24 microns, the first core layer 2, the second core layer 3 and the third core layer 4 The thicknesses are all 5 microns, and the thickness of the adhesive layer 6 is 5 microns.

[0038] Raw materials for each layer, surface layer 1: 40kg of polyamide, 40kg of polyolefin, 60kg of polyester (polyethylene terephthalate), wherein the polyolefin is specifically 10kg of ethylene-α-olefin copolymer (α-olefin is hexene-1) , with a density of 0.90g / cm 3 , and 30kg of ethylene-vinyl acetate copolymer;

[0039] The first core layer 2: polyamide 50kg; the second core layer 3: ethylene-vinyl alcohol copolymer layer 100kg; the third core layer 4: 98kg vinylidene chloride-maleic anhydride copolymer (melting point 150 ° C, density 1.7 g / cm 3 ) and 2kg of epoxidized soybean oil; inner layer 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com