Gas-phase antirust film containing microcapsules

A gas-phase anti-rust and gas-phase anti-rust agent technology, which is applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of human and animal injury, anti-rust agent toxicity, and insufficient anti-rust time, etc. Problems, achieve the effect of overcoming poor oxygen and water vapor barrier performance, strong puncture and tear resistance, and excellent timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: adopt the production equipment of free radical polymerization, drop into wall material styrene monomer 1kg, core material 2-methylimidazole and 2-ethyl-4-methylimidazole 5kg, emulsifier NP-10 in 20kg toluene 0.05kg of initiator 0.01kg, mechanically stirred for 3h after being heated to 80°C, vacuumized, filtered, and washed to obtain 3kg of microcapsules containing a gas-phase rust inhibitor with an average particle diameter of 29 μm. The polystyrene content of the microcapsules is 0.8 kg, and the content of 2-methylimidazole and 2-ethyl-4-methylimidazole is 2.2 kg.

Embodiment 2

[0022] Embodiment 2: adopt the production equipment of interfacial phase separation, drop into polyacrylonitrile 1kg, 4-(N,N-di-n-butyl)-amine-methylmorpholine 7kg, emulsifier in 20kg butanone and toluene mixed solution Sodium dodecylbenzenesulfonate 0.1kg, after stirring for 4h, vacuumize, filter and wash to obtain 2.3kg of microcapsules containing gas-phase rust inhibitor with an average particle diameter of 0.5 μm. The content of polyacrylonitrile in the microcapsule is 0.5 kg, and the content of 4-(N,N-di-n-butyl)-amine-methylmorpholine is 1.8 kg.

Embodiment 3-8

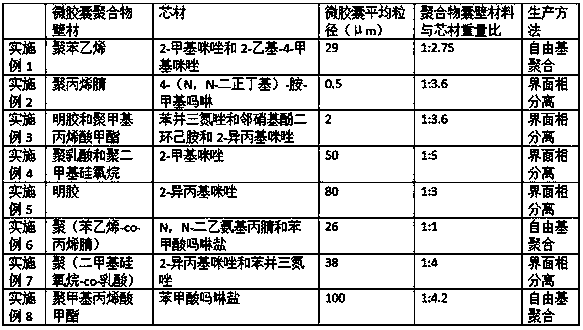

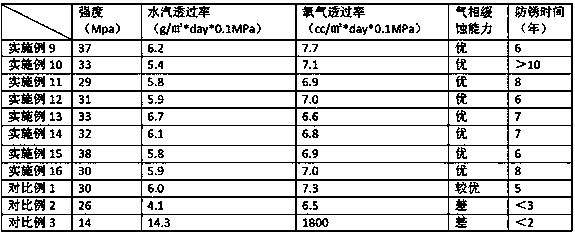

[0023] Examples 3-8, with reference to the preparation method of Example 1 or 2, adjust the wall material and core material of the microcapsule polymer to obtain microcapsules with different average diameters and different ratios of wall material and core material. The specific parameters are shown in Table 1 .

[0024] Table I

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com