Heat-shrinkable bag for packaging marine product

A heat-shrinking, seafood technology, used in packaging, wrapping paper, layered products, etc., can solve the problems of low shrinkage, large shrinkage force, and poor barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

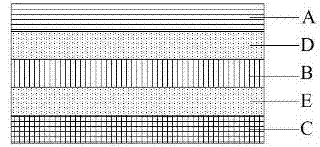

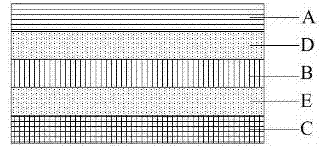

[0022] First prepare the raw materials of each layer, core layer B: 49kg of VDC-MA copolymer and 1kg of epoxidized soybean oil. Surface layer A: 40kg of ethylene-octene-1 copolymer and 60kg of ethylene-vinyl acetate copolymer, the density of ethylene-octene-1 copolymer is 0.90g / cm 3 , the density of ethylene-vinyl acetate copolymer is 0.935 g / cm 3 . Heat seal layer C: 70kg of ethylene-octene-1 copolymer and 29kg of LLDPE, the density of ethylene-octene-1 is 0.89g / cm 3 , the density of LLDPE is 0.917g / cm 3 , 1kg processing aid; adhesive layer D and adhesive layer E: 12kg of EVA, density 0.935g / cm 3 .

[0023] The raw materials of each layer are added to the extruder of each layer to melt and plasticize, and then enter a multi-layer co-extrusion circular die to distribute the melt to form a multi-layer circular melt tube; The body tube blank is cooled and formed by vacuum sizing, and then enters the hot water tank to be heated to a suitable blowing temperature, and the com...

Embodiment 2

[0025] Prepare the raw materials of each layer first, core layer B: 49kg of VDC-MA copolymer and 1kg of epoxy soybean oil. Surface layer A: 40kg of ethylene-hexene-1 copolymer and 60kg of ethylene-vinyl acetate copolymer, the density of ethylene-hexene-1 copolymer is 0.91g / cm 3 , the density of ethylene-vinyl acetate copolymer is 0.935 g / cm 3 . Heat seal layer C: 70kg of ethylene-hexene-1 copolymer and 29kg of LLDPE, the density of ethylene-hexene-1 is 0.91g / cm 3 , the density of LLDPE is 0.917g / cm 3 , 1kg processing aid; adhesive layer D and adhesive layer E: 12kg of EVA, density 0.935g / cm 3 .

[0026] Other methods and structures are the same as in Example 1.

Embodiment 3

[0028] Prepare the raw materials of each layer first, core layer B: 49kg of VDC-MA copolymer and 1kg of epoxy soybean oil. Surface layer A: 40kg of ethylene-octene-1 copolymer and 60kg of ethylene-vinyl acetate copolymer, the density of ethylene-octene-1 copolymer is 0.90g / cm 3 , the density of ethylene-vinyl acetate copolymer is 0.935 g / cm 3 . Heat seal layer C: 70kg of ethylene-octene-1 copolymer and 29kg of VLDPE, the density of ethylene-octene-1 is 0.89g / cm 3 , the density of VLDPE is 0.905g / cm 3 , 1kg processing aid; adhesive layer D and adhesive layer E: 12kg of EVA, density 0.935g / cm 3 .

[0029] Other methods and structures are the same as in Example 1.

[0030] After testing, the main performance indicators of the heat-shrinkable bag for seafood packaging obtained by adopting the technical solution of the present invention are shown in Table 1.

[0031] Table 1

[0032] Test items Example 1 Example 2 Example 3 Longitudinal and tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com